Monster Mash

Well-Known Member

The only drawback is flame control. If you see a boil over coming on there is little you can do about it.

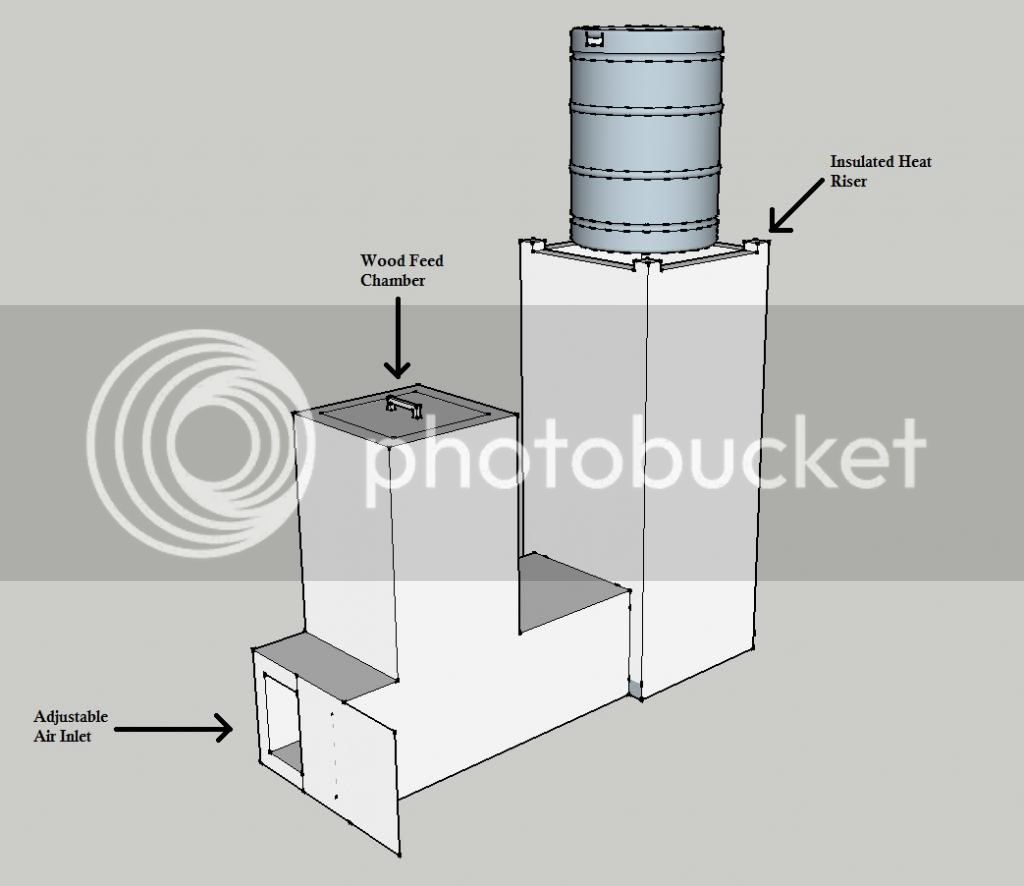

As a general rule of thumb it seems like a horizontal chamber diameter of half of the burn chamber diameter is the sweet spot, with a heat riser diameter as large or larger than the burn chamber.

I guess the one improvement that everybody says is necessary is temperature control.

But it is good to know that if the world goes to sh!t we can still brew beer, just camp out near a grain silo

Yeah I am with both of you on that. I am thinking this would be no problem to be the boil kettle. My worry would be that for an HLT it would be too difficult to hit target temperature without an under/overshoot for your mash...