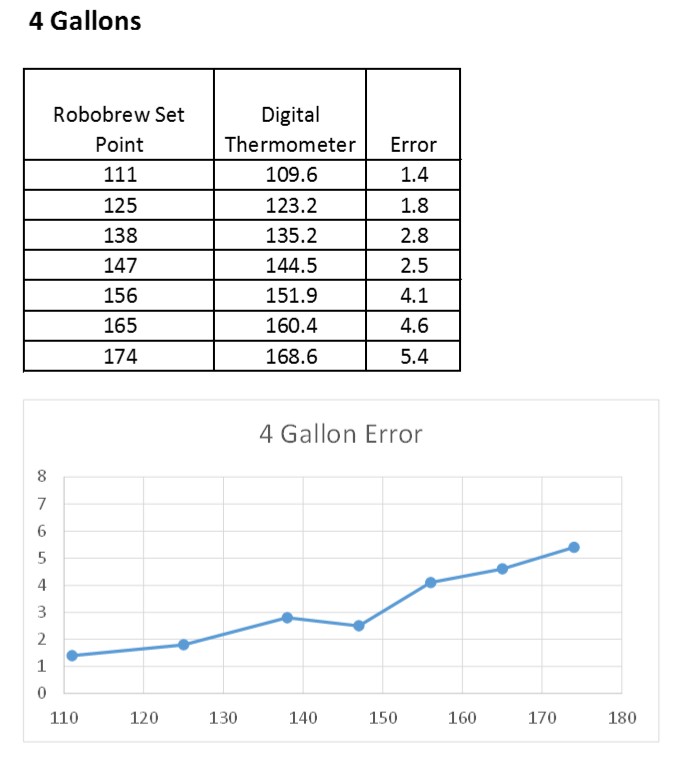

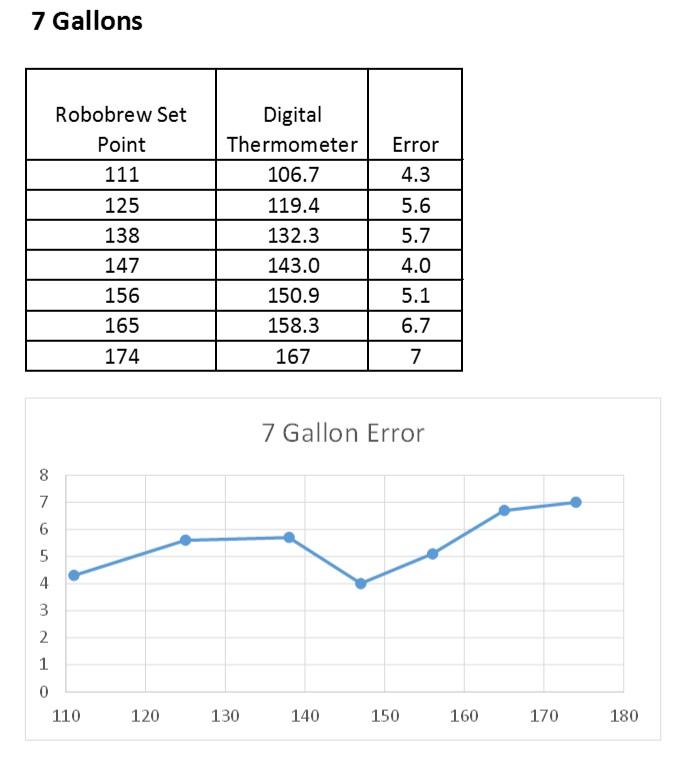

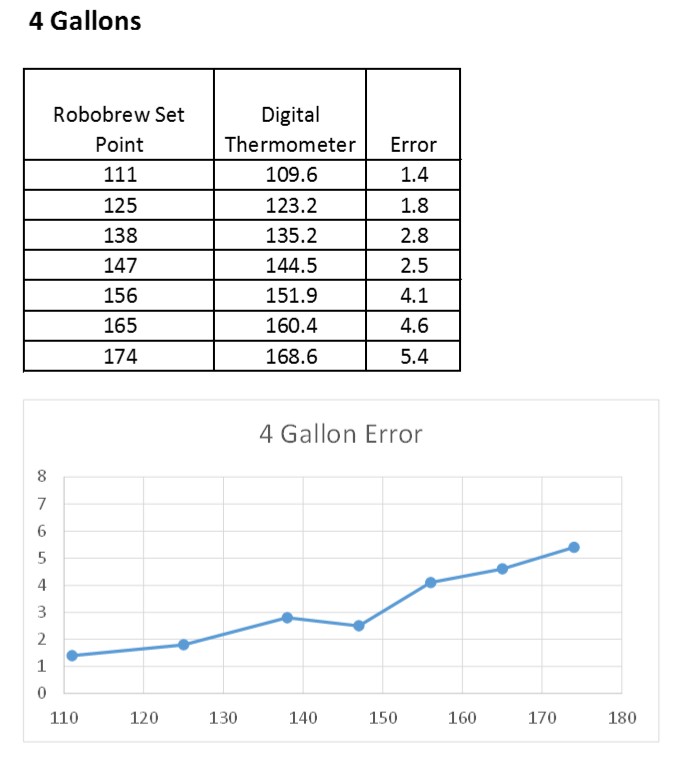

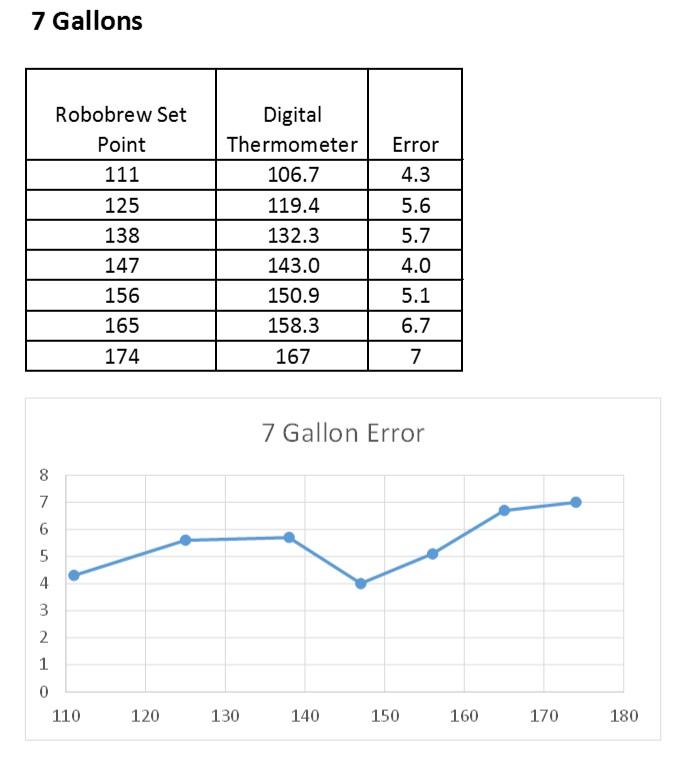

I recently spent some time with a Robobrew electric unit, trying it out. I made 2 batches of beer and found some significant temperature discrepancies between what the unit was reading and what I measured with my lollipop digital thermometer. So I did a couple of experiments heating strike water to different temperatures and I recorded the temperature with my thermometer and compared it to what the Robobrew was reading.

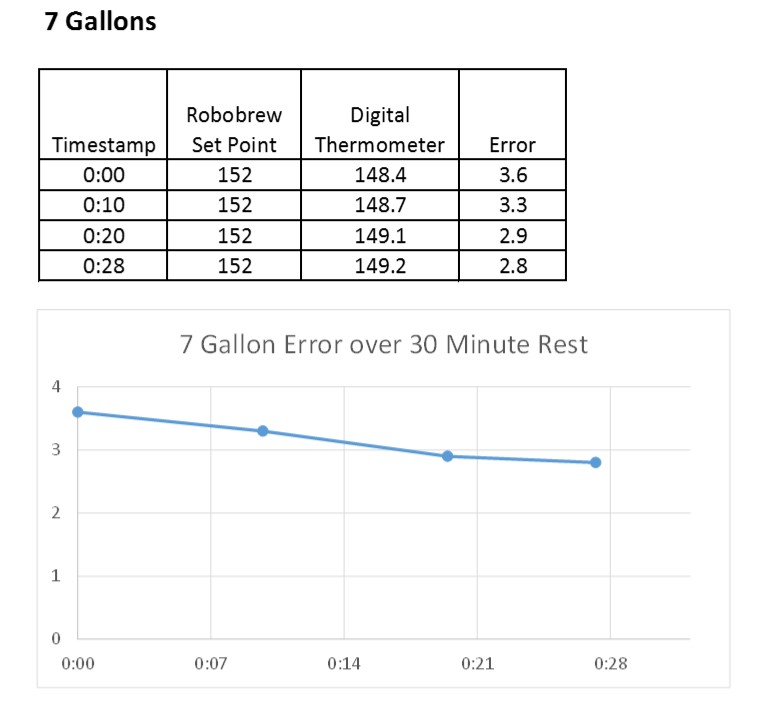

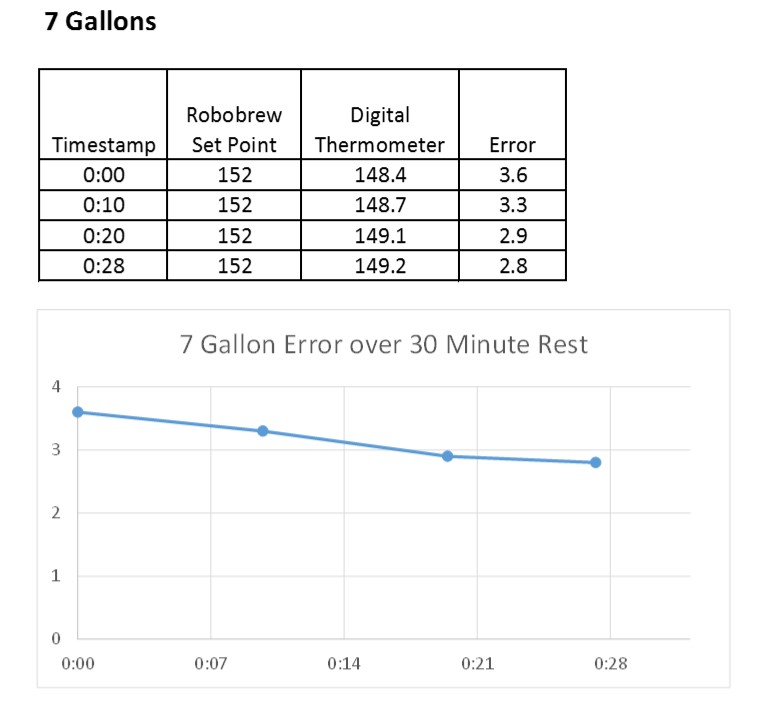

I found that there were some significant differences, but the unit held temperature very steady at a set point. The controller was intelligent enough to just turn on the 500W element, even though the switch was on allowing it to use either the 1000W, 500W, or both combined. So it had gradual temperature control as I kept in recirculation (with the recirc pipe valve 1/2 open).

With these kind of numbers, although I'd have to do some mental math and adjust set the controller to a higher set point than what I wanted in the rest of the mash, I could still use the system and controller as they were to provide good control. I'm not sure I'd even bother with insulation either since the level of temperature control while recirculating was pretty impressive (within 1 degree and very stable).

Have any other Robobrew users done any similar temperature measurements or messed around with insulation?

Full review is here: http://www.homebrewfinds.com/2017/10/hands-on-review-robobrew-all-grain-brewing-system.html

I found that there were some significant differences, but the unit held temperature very steady at a set point. The controller was intelligent enough to just turn on the 500W element, even though the switch was on allowing it to use either the 1000W, 500W, or both combined. So it had gradual temperature control as I kept in recirculation (with the recirc pipe valve 1/2 open).

With these kind of numbers, although I'd have to do some mental math and adjust set the controller to a higher set point than what I wanted in the rest of the mash, I could still use the system and controller as they were to provide good control. I'm not sure I'd even bother with insulation either since the level of temperature control while recirculating was pretty impressive (within 1 degree and very stable).

Have any other Robobrew users done any similar temperature measurements or messed around with insulation?

Full review is here: http://www.homebrewfinds.com/2017/10/hands-on-review-robobrew-all-grain-brewing-system.html

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)