Alright fellow Robobrew and Brewzilla friends its story time from your favorite (or not) Brewzilla 65 L brewer!

Today was a momentous day at Big Three Brewing Co (my garage brewery). As i said in a previous post I pulled the trigger on a Brew Bag BIAB with some birthday money!

I awoke at 5:30 AM turned on the lights to the garage and found my strike water ready to go. Added my water salts, mixed and turned on the pump for absolutely no reason.

I then went to the basement grabbed my assorted grain weighed everything out (19 lbs) and milled it into the brew bag. I crushed super fine and completely forgot to wet the grain before milling but oh well I knew the BIAB could handle it.

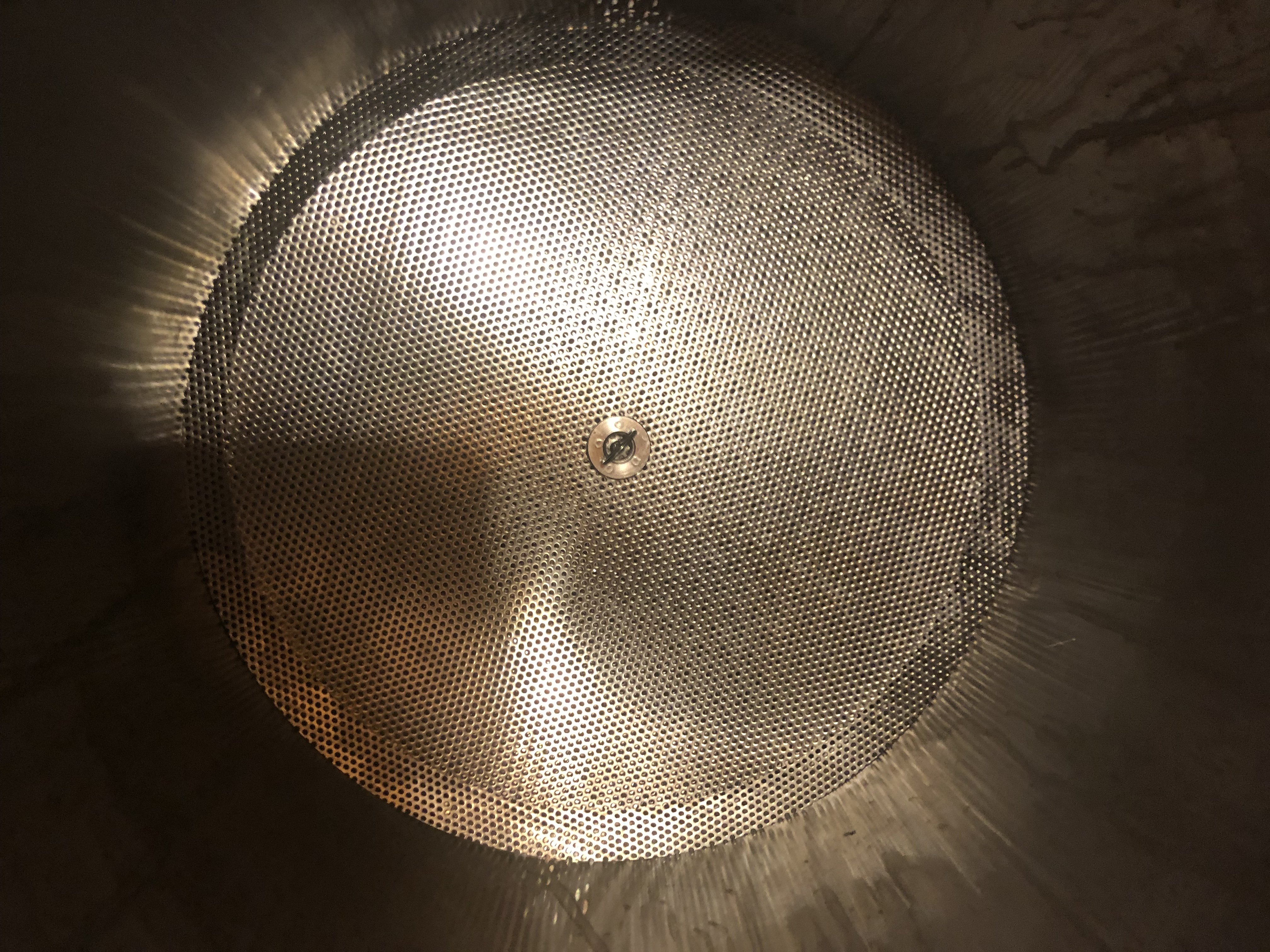

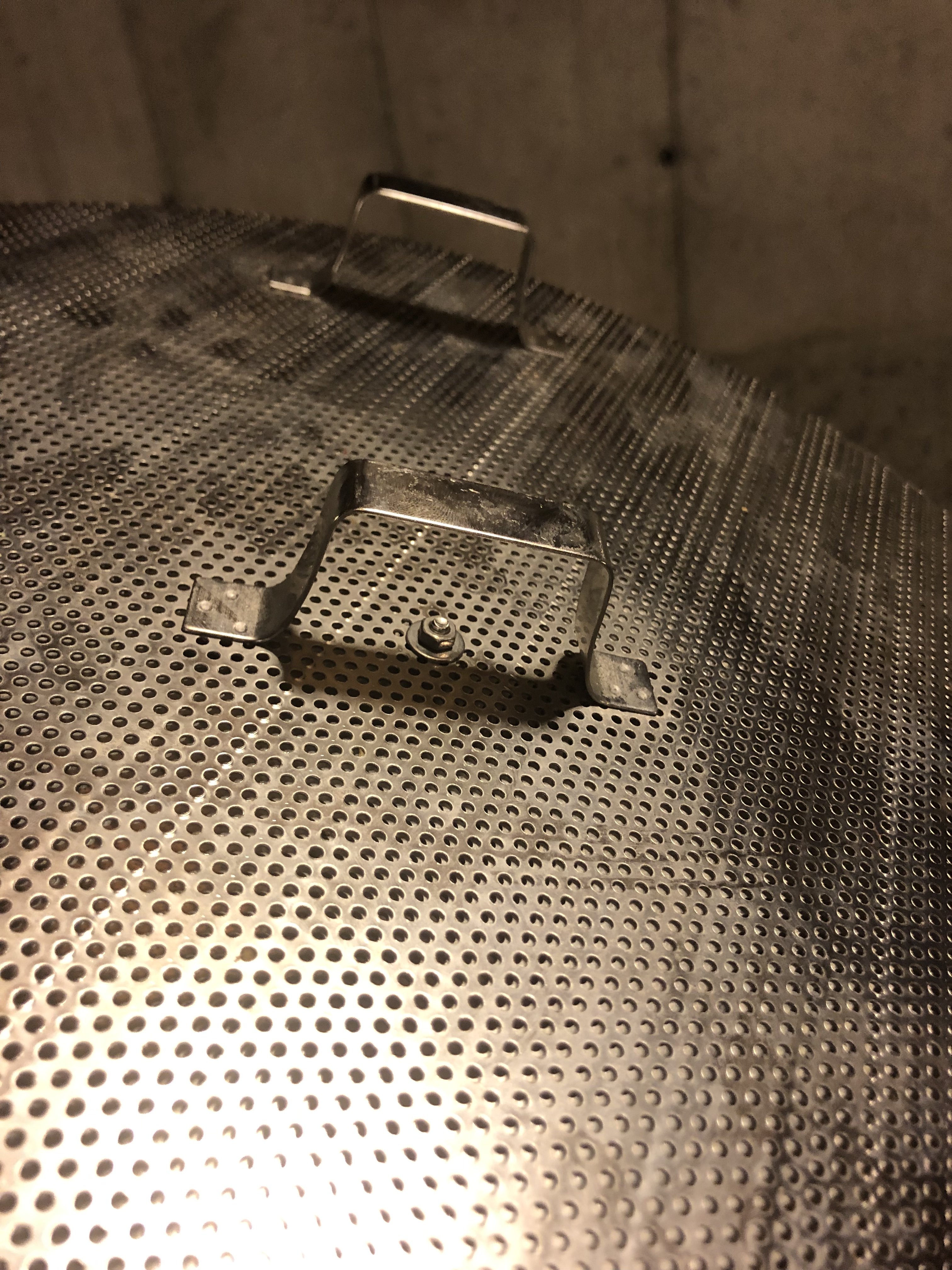

What comes next may shock you...after reading that two of you had issues without the malt pipe using a bag I said to myself how can I reinforce the hop blocker false bottom? Well as a man with two Masters Degrees (None of which are in engineering) I decided to add the false bottom of the malt pipe on top of the hop blocker and connected it with the bolt and nut. I said to myself, Sammy, this is either genius or really stupid but F it lets give it a go.

So i put my bag on the pulley lifted it up and slowly dropped it down into the strike water...no issues.

Did my normal multi-step mash at 144 and 162 ( thanks

@bracconiere) and slowly lifted the bag out and squeezed the heck out of it!

I then sparged from my Digiboil using my new pump (another birthday gift to myself and went about the boil.

Threw hops in as usual, whirlpooled and chilled using a CFC as usual and got everything into the two fermentors missing a half gallon because I forgot to update my profile in Brewers Friend...o thee well.

Happy to report the hop blocker false bottom didn't budge! Was completely flat as usual! Was it a little more pain in the butt to clean up with some hop material in between the two metal sheets...sure but it worked!

So fellow brewers, the moral of the story is you can use a bag in the Brewzilla 65 L without it concaving!

Thank you for coming to my Ted Talk.

Edit: 92% Efficiency 85% BH

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)