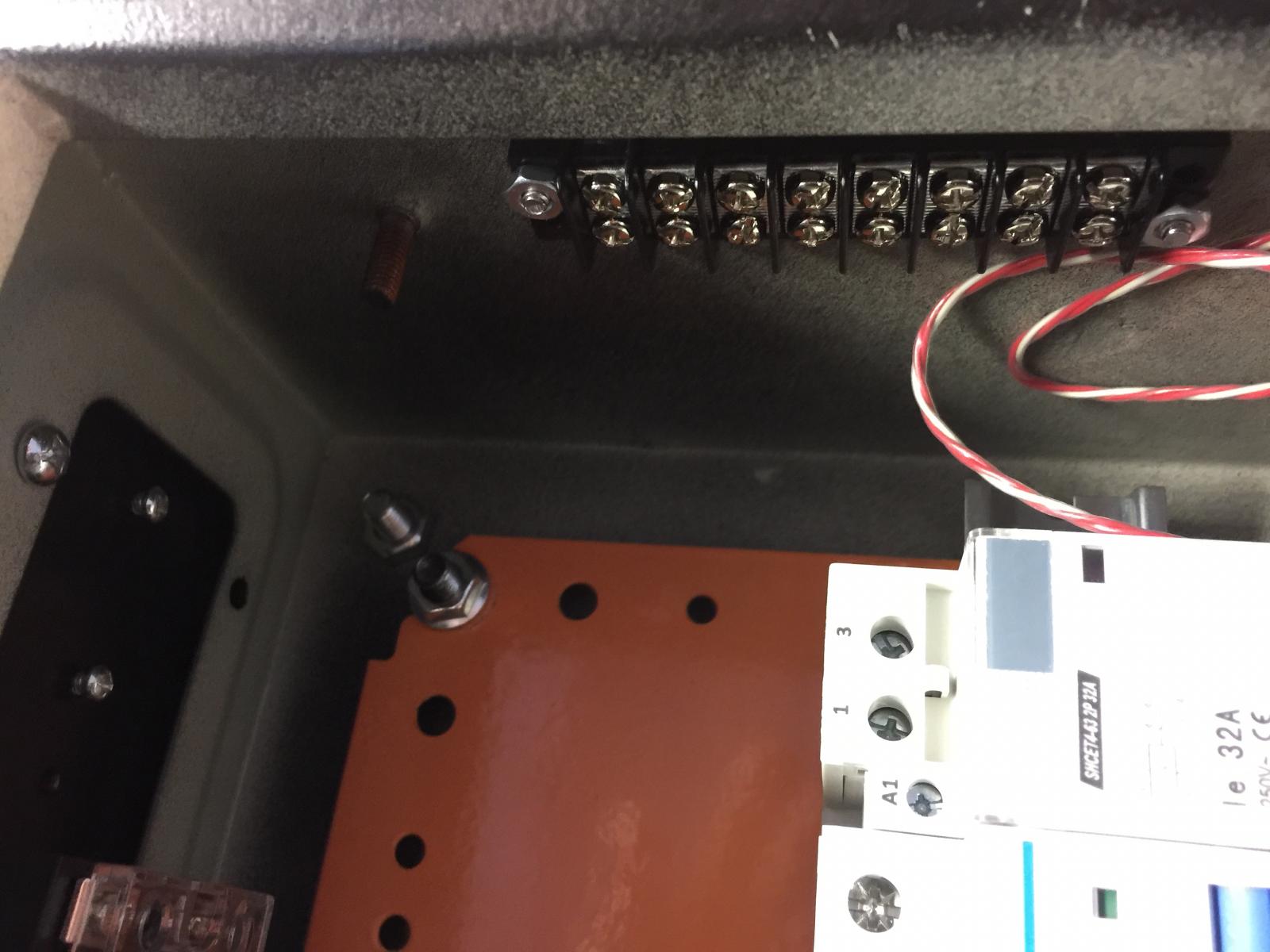

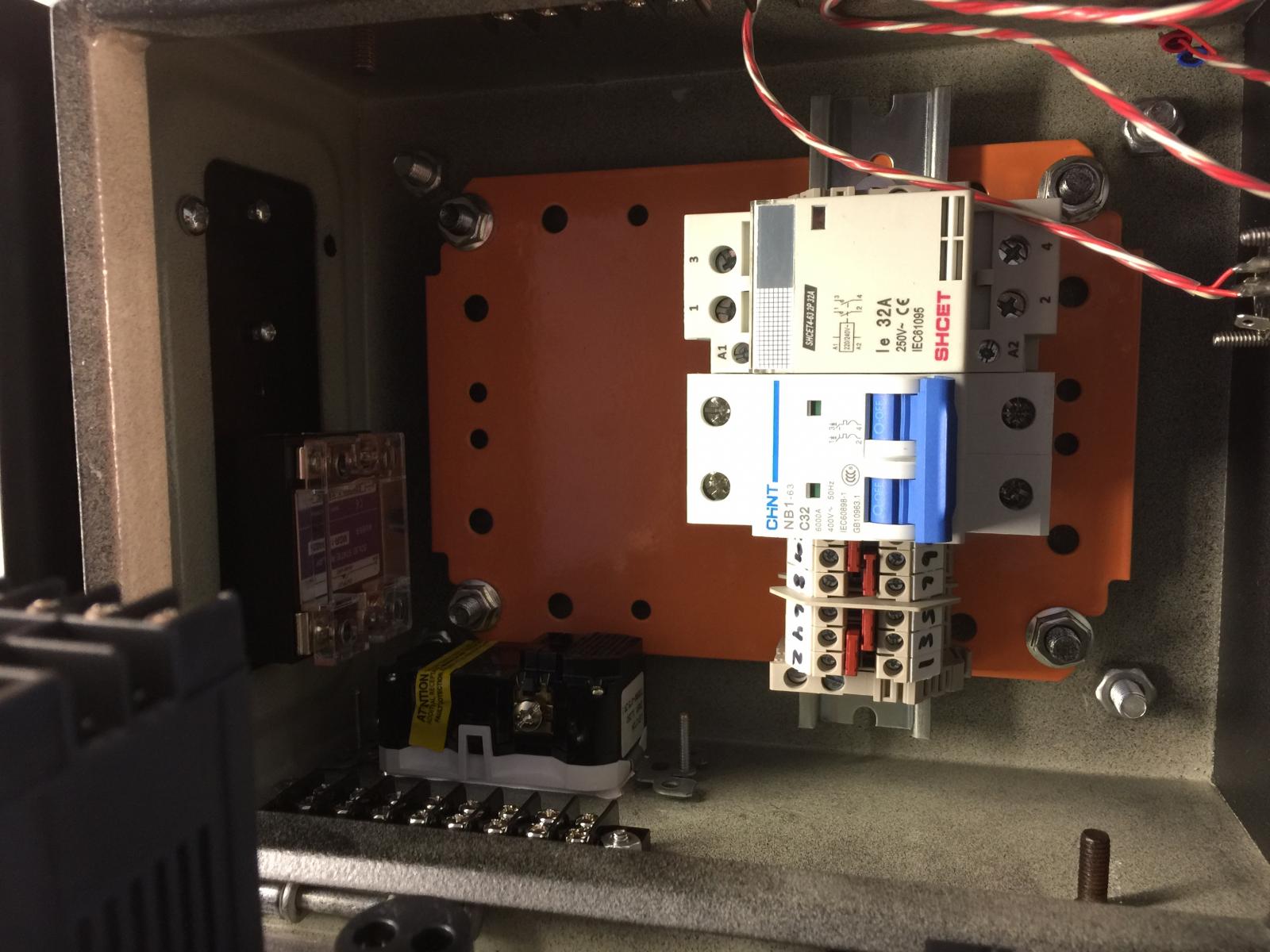

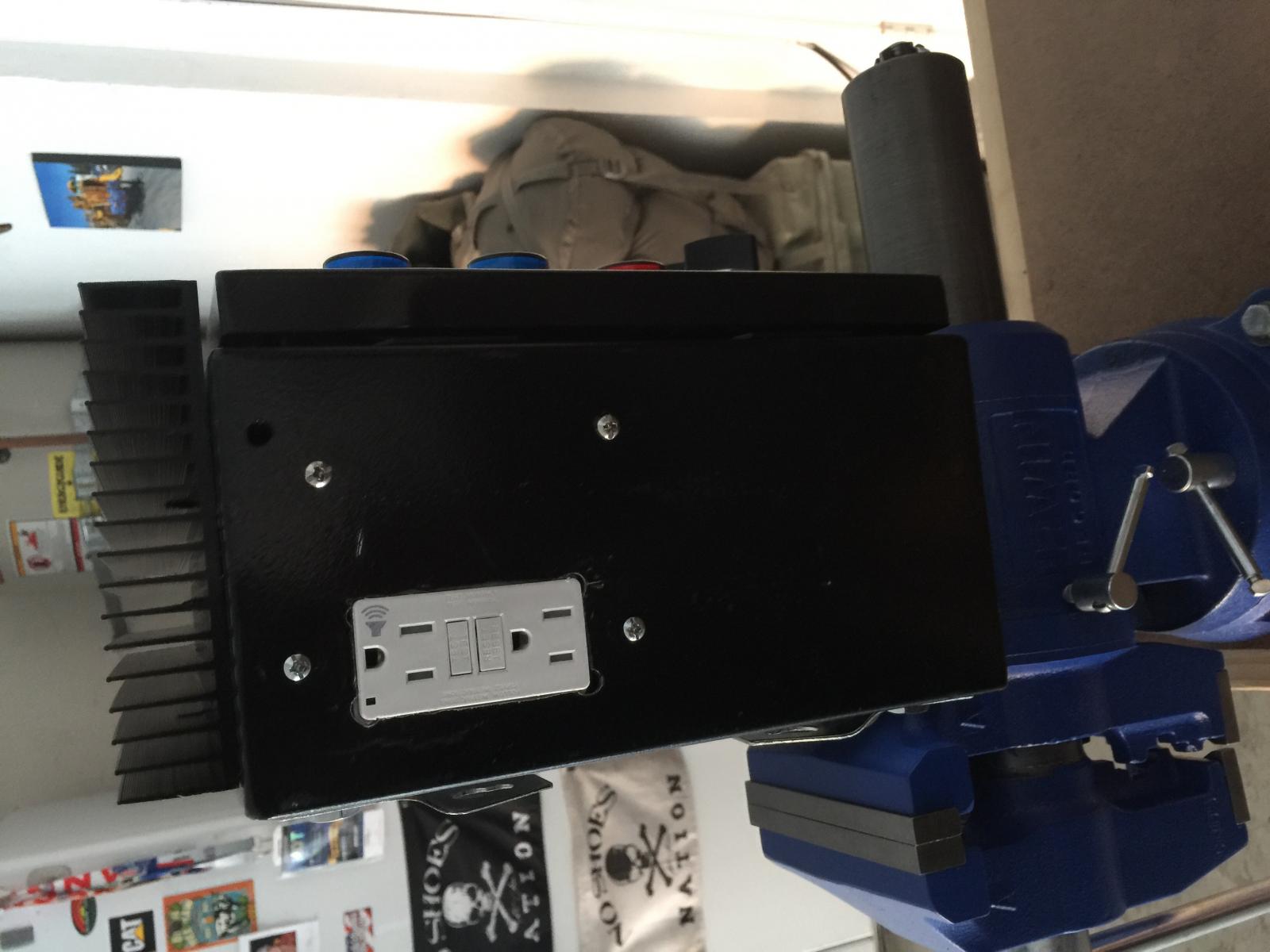

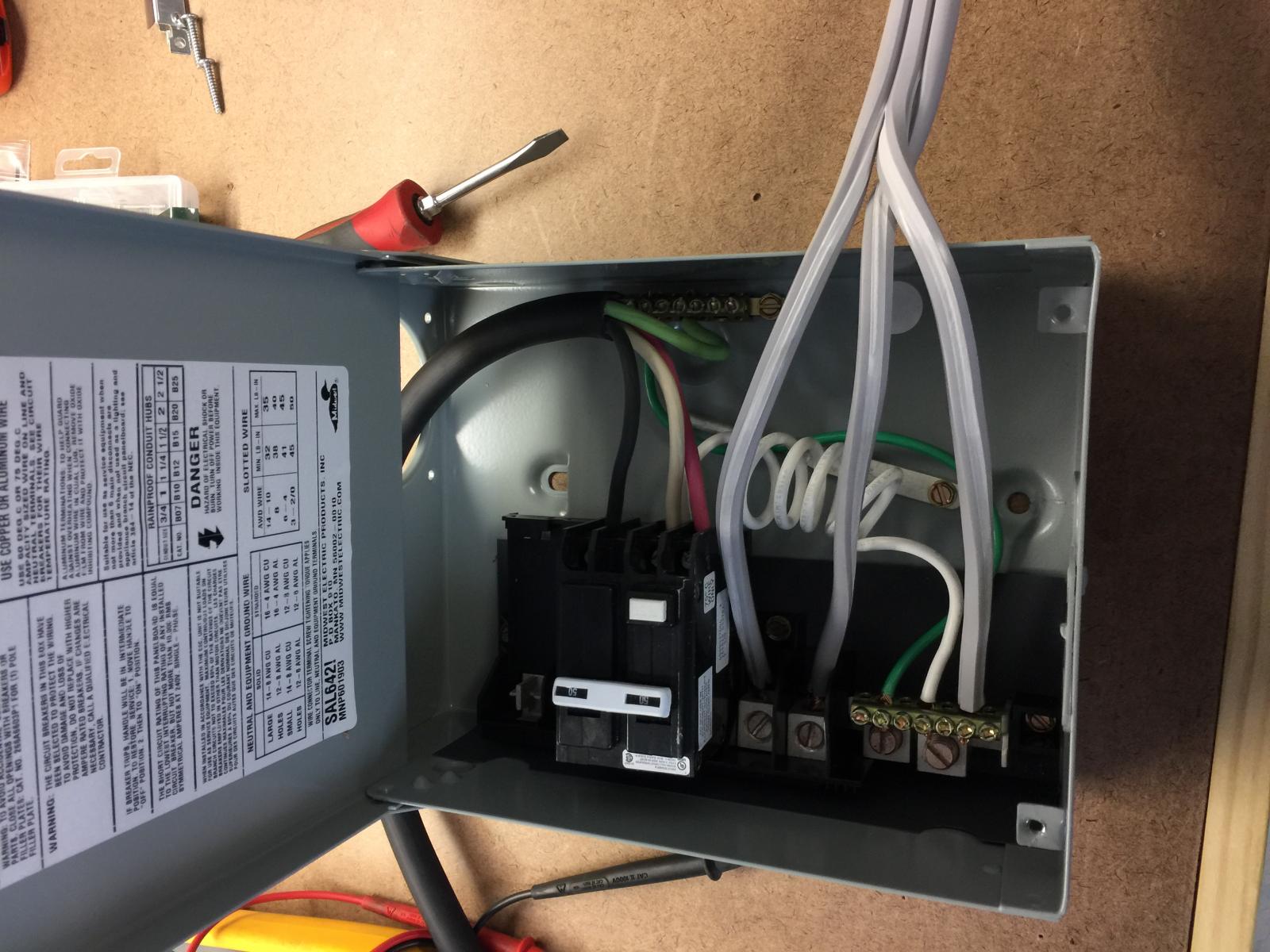

I was thinking power comes in through the contacts and splits into separate legs in the box. Basically everything in the box is powered by 120v except the heating element. I was trying to figure out if I can use 120v on the PID and low voltage/amperage side of the SSR and 240v on the high side?

Power comes in split as two 120V legs. The contactor just switches both legs, so that when the contactor coil is not energized, not current or voltage is on the load side of the contactor. Nothing splits after the contactor. You can use one of the 120V legs and neutral to power any 120V device. As said previously, if you use a 4 wire feed derived from a 3 wire feed (via a spa panel) you should balance the current draw of the 120V devices between the two 120V hot legs. If you don't understand how to do this, you really should get some local help with electrical expertise.

Do you have a circuit drawing of the design you are using?

Brew on

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)