BlichmannEngineering

Well-Known Member

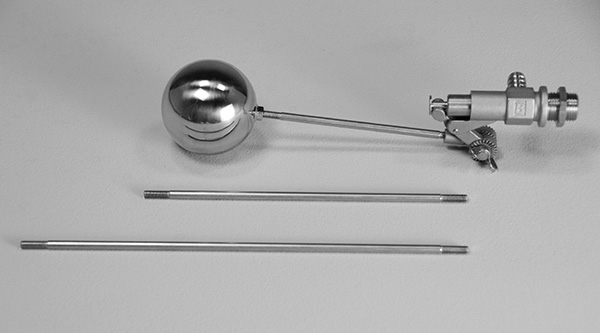

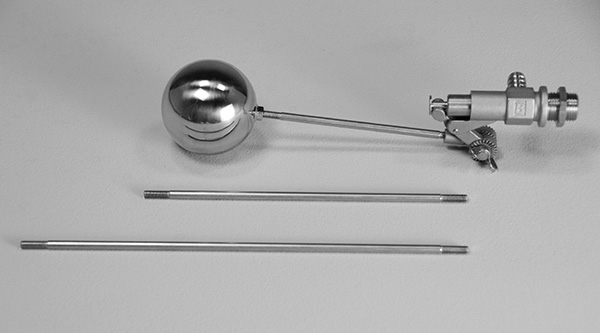

Just added an updated product to our web page - the redesigned AutoSparge. We had a lot of feedback from brewers wanting an all stainless valve body and hose float ball. We've worked with our suppliers to implement it at a $20 price increase. $70 for the complete assembly. We've improved the mounting threads with a hybrid - NPT on the first half and straight where it mounts to the pot/cooler for better mounting and flexibility of hose connectors and fitting types. We've also closed up the clearances of the shaft a bit to reduce bypass flow. Not sure that many people know, but we've added two longer float arms this past summer to increase the operational range for larger pots.

All of these were things we heard through our feedback page so thanks for the input!

John B

Here is a link to the page: http://www.blichmannengineering.com/products/autosparge™

All of these were things we heard through our feedback page so thanks for the input!

John B

Here is a link to the page: http://www.blichmannengineering.com/products/autosparge™

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)