Hello all,

I have been searching the forum for pump mounting hardware options and having a heck of a time finding a thread that talks about the hardware options for pump mounting.

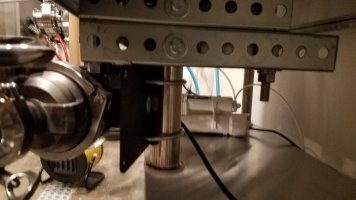

I currently have 2 different types of mounts employed in the brewery. The old fashioned U bolts, and some pipe standoffs. In each of these instances the pumps are mounted to a leg.

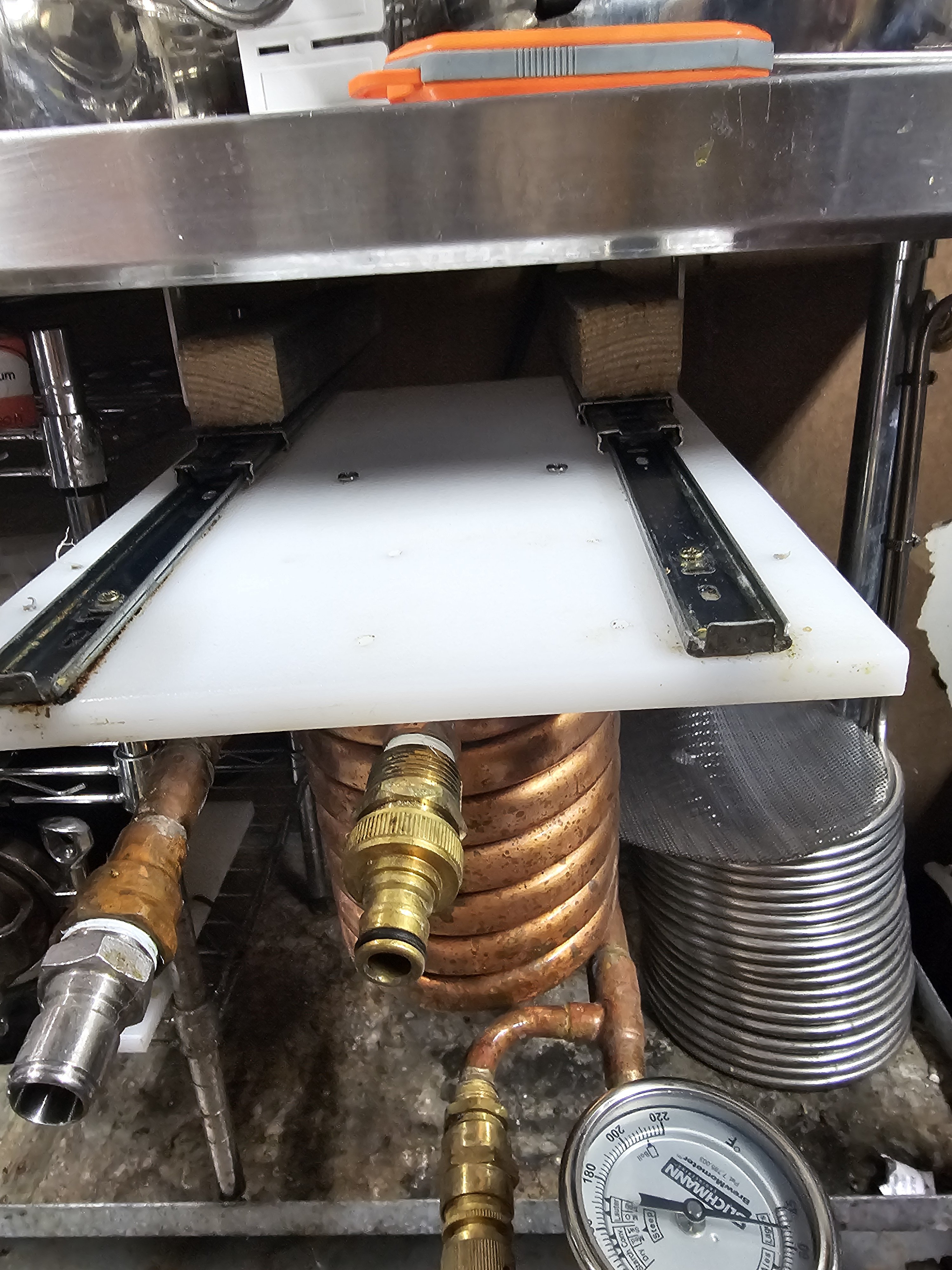

I am looking for another option for the underside of my brew table. I run a third pump so that each vessel has its own deicated pump. The table looks like this. Originally it just sat on the lower shelf, but i would like a way to mount it to the underside of the talbe, possibley with a little bit of a stand off. I can drill through the table but it doesnt keep it Low enough to bring it out from under the table a bit for the out flow. The pump i am trying to mount is a spike flow.

I am hoping for other suggestions, or suggested options. I look forward to what the forum can suggest, or being politly pointed to an existing thread i missed.

thanks you all for the help

I have been searching the forum for pump mounting hardware options and having a heck of a time finding a thread that talks about the hardware options for pump mounting.

I currently have 2 different types of mounts employed in the brewery. The old fashioned U bolts, and some pipe standoffs. In each of these instances the pumps are mounted to a leg.

I am looking for another option for the underside of my brew table. I run a third pump so that each vessel has its own deicated pump. The table looks like this. Originally it just sat on the lower shelf, but i would like a way to mount it to the underside of the talbe, possibley with a little bit of a stand off. I can drill through the table but it doesnt keep it Low enough to bring it out from under the table a bit for the out flow. The pump i am trying to mount is a spike flow.

I am hoping for other suggestions, or suggested options. I look forward to what the forum can suggest, or being politly pointed to an existing thread i missed.

thanks you all for the help