Lumpyyyyy

Well-Known Member

I am working on putting together a build that will allow me to run a BIAB off a single element. The requirements that I have given myself are as follows:

1. 240V (Access to current 240V supply through laundry outlet and panel in basement when basement room refinished)

2. Single element

3. All items purchased should be expandable to 3 vessel setup (with exception of enclosure)

4. Use PID controller

5. Switches to turn on and off elements/pumps rather than push button illuminated LEDs

6. RTD Elements

7. Single Pump

In doing my work, I came across the following kit on eBrew Supply:

http://www.ebrewsupply.com/shop/ebrew-kits/ebrew-pid-kits/1-pid-30a-biab-kit.html

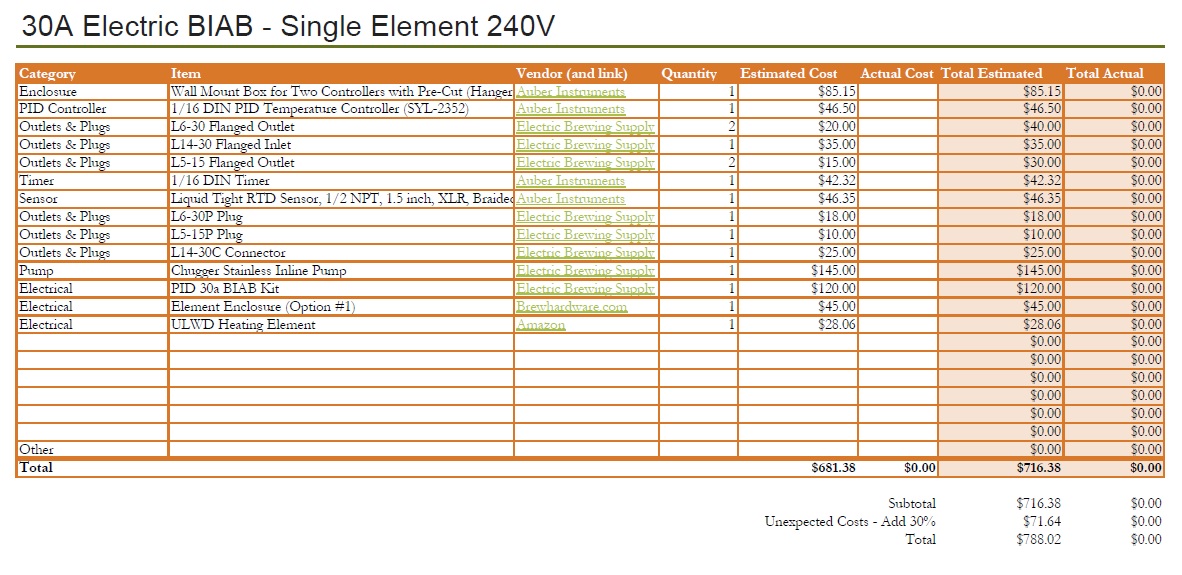

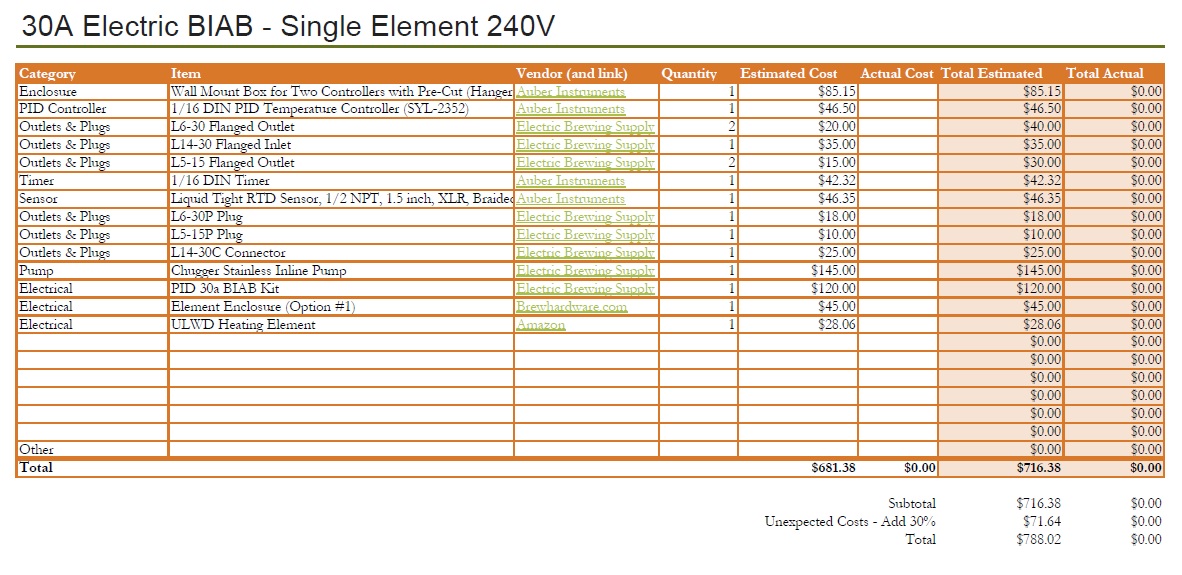

It contains (seemingly) the majority of the items I needed to put together my system. I have the following items to purchase extra:

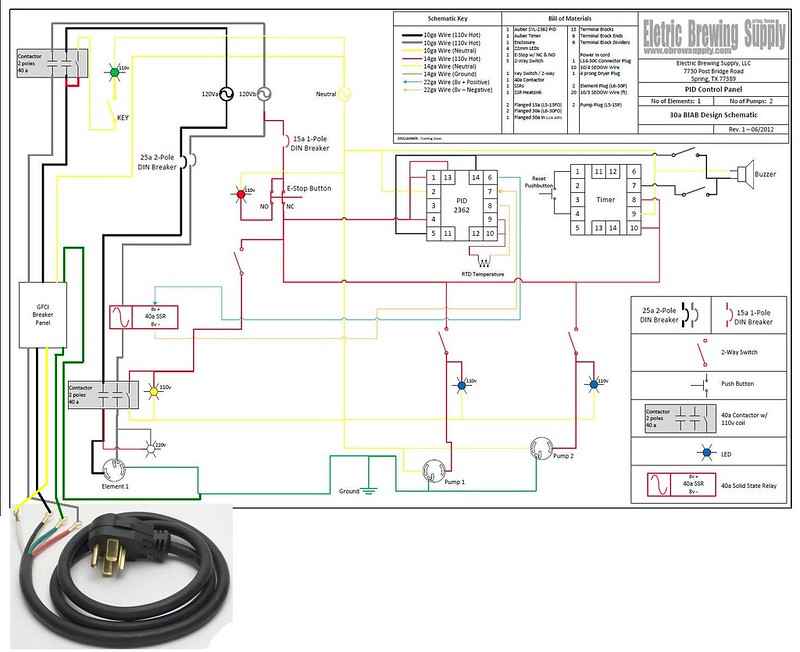

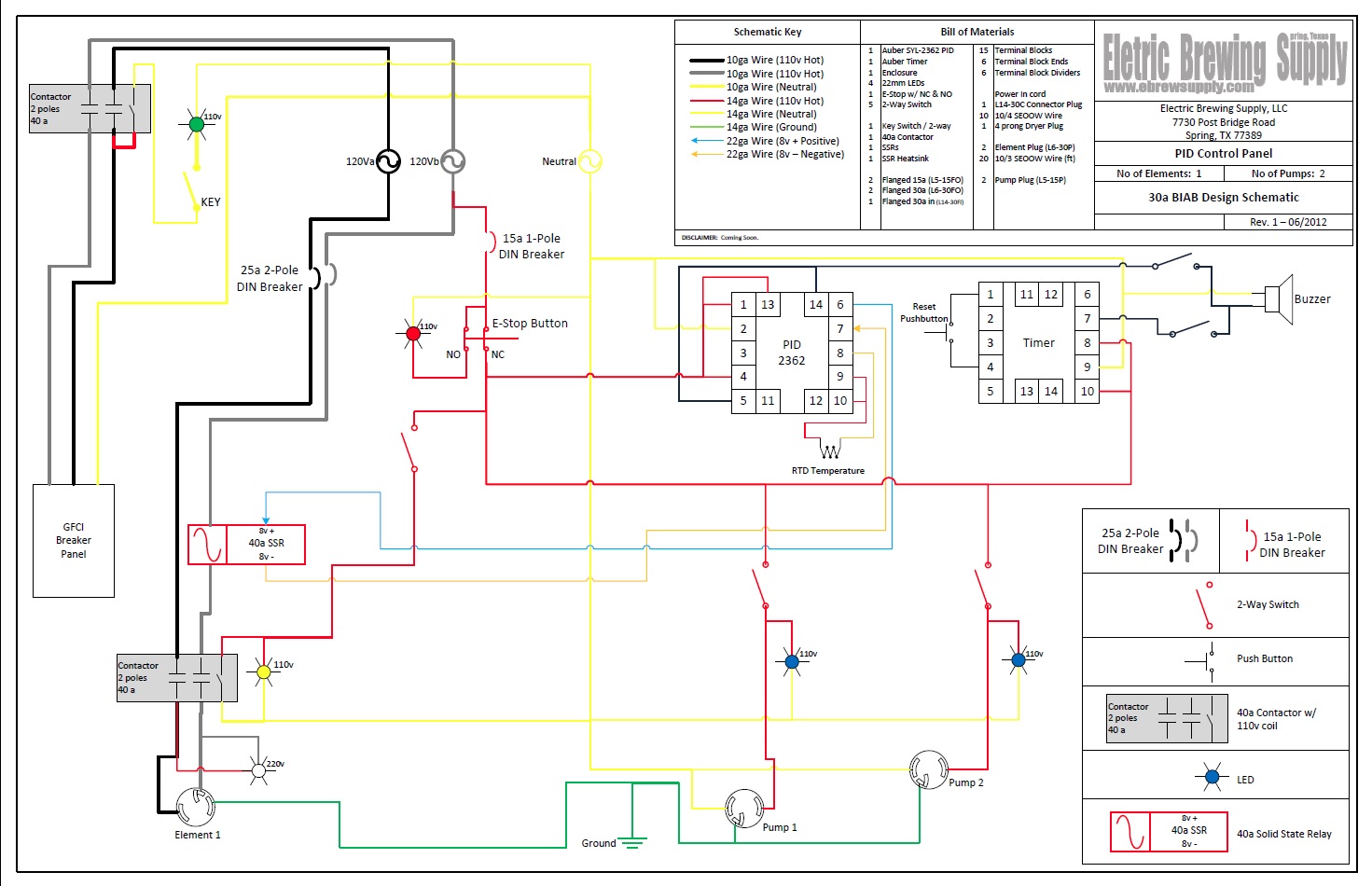

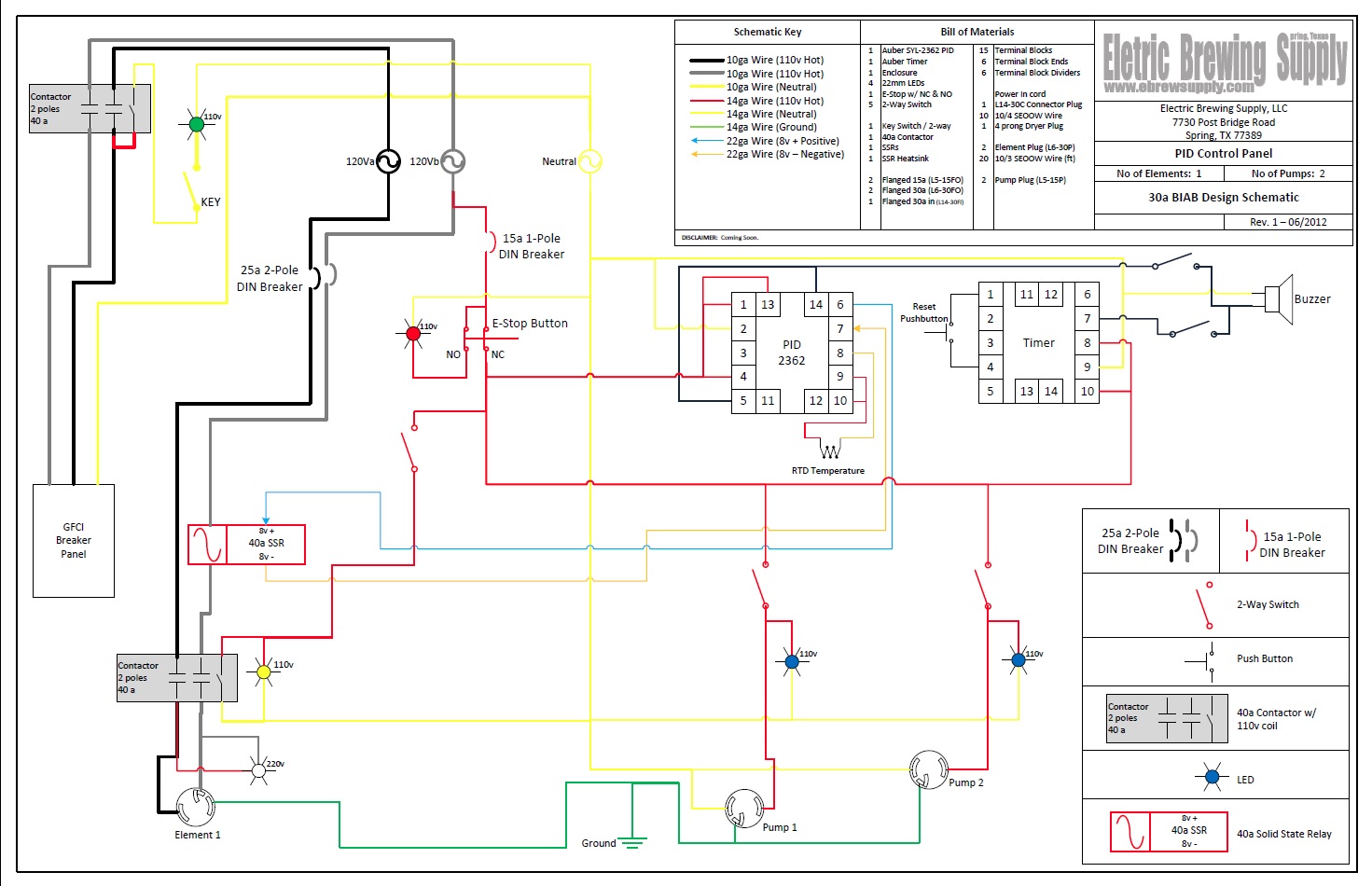

And here is the wiring schematic I am going to follow:

My questions are as follows:

The outlet near my dryer is 4 pins while the wiring diagram only shows 3 in. Can someone explain this to me?

Does anyone see anything I missed out on in my BOM? Other than kettle which I will already have.

If anyone has any constructive criticism, I'm all for it. Please let me know. Minus the pump, I'm around 600 which seems pretty reasonable for this type of setup.

1. 240V (Access to current 240V supply through laundry outlet and panel in basement when basement room refinished)

2. Single element

3. All items purchased should be expandable to 3 vessel setup (with exception of enclosure)

4. Use PID controller

5. Switches to turn on and off elements/pumps rather than push button illuminated LEDs

6. RTD Elements

7. Single Pump

In doing my work, I came across the following kit on eBrew Supply:

http://www.ebrewsupply.com/shop/ebrew-kits/ebrew-pid-kits/1-pid-30a-biab-kit.html

It contains (seemingly) the majority of the items I needed to put together my system. I have the following items to purchase extra:

And here is the wiring schematic I am going to follow:

My questions are as follows:

The outlet near my dryer is 4 pins while the wiring diagram only shows 3 in. Can someone explain this to me?

Does anyone see anything I missed out on in my BOM? Other than kettle which I will already have.

If anyone has any constructive criticism, I'm all for it. Please let me know. Minus the pump, I'm around 600 which seems pretty reasonable for this type of setup.