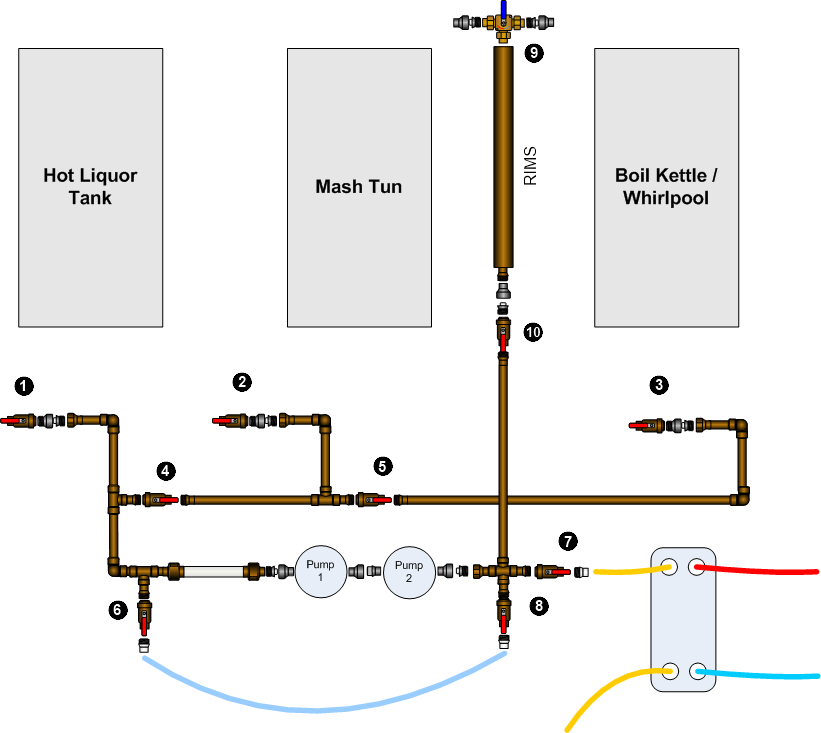

Well we have decided to upgrade our system from 1/2 quick disconnects to hard plumbed system with camlocks and 1/2 copper. The design will allow us to simplify our brew day by opening & closing valves. For cleanup the camlocks will unlock and allow easy cleaning and the mash tun will be on a tippy so we can dump the grains during the boil.

All valves are 1/2 standard ball valves except 9 which is a 3 way to allow flow out of the rims to the mash tun or boil kettle during whirlpool.

Here is the valve positions during the brew day:

Fill Mashtun

1) Open

2) Close

3) Close

4) Close

5) Close

6) Close

7) Close

8) Close

9) Open to Mashtun

10) Open

Mashing - Pump 1 On Rims on when temp needs to be raised

1) Close

2) Open

3) Close

4) Open

5) Close

6) Open - Bypass loop

7) Close

8) Open - Bypass loop

9) Open to Mashtun

10) Open part way to keep 1/2" wort above grain.

Transfer 1st Runnings

1) Close

2) Open

3) Close

4) Open

5) Close

6) Close

7) Close

8) Close

9) Open to Kettle

10) Open Full

Batch Sparge (same as fill mashtun process)

Transfer 2nd Runnings (same as Transfer 1st Runnings)

Whirlpool - Pumps 1 & 2 on

1) Close

2) Close

3) Open

4) Open

5) Open

6) Close

7) Close

8) Close

9) Open to Kettle

10) Open Full

Transfer to Chiller - all wort in system drained from 6 & 8 for starter or add to the batch.

1) Close

2) Close

3) Open

4) Open

5) Open

6) Close

7) Open

8) Close

9) Open to Kettle

10) Close

What do you guys think?

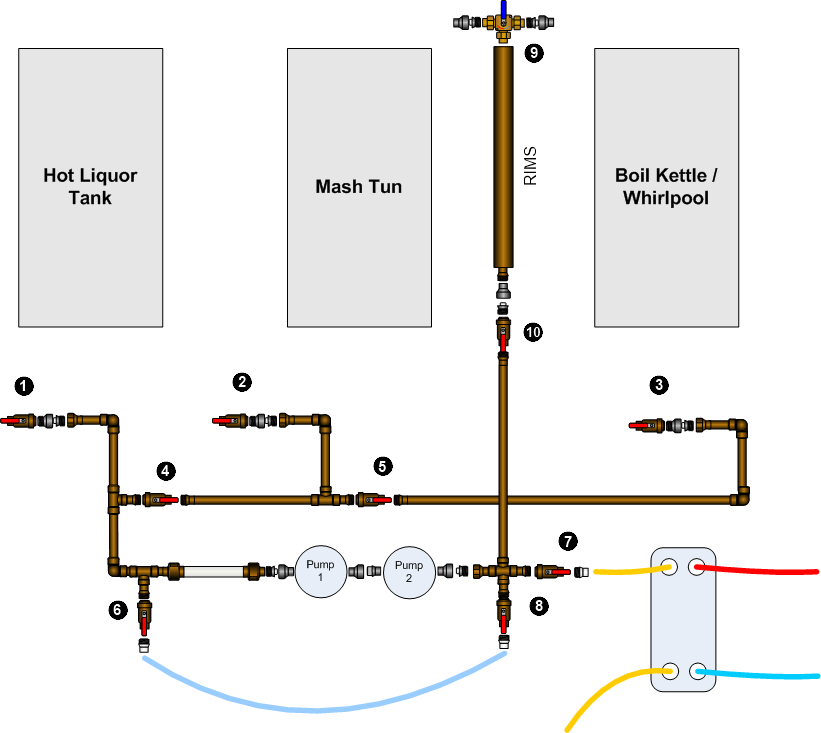

All valves are 1/2 standard ball valves except 9 which is a 3 way to allow flow out of the rims to the mash tun or boil kettle during whirlpool.

Here is the valve positions during the brew day:

Fill Mashtun

1) Open

2) Close

3) Close

4) Close

5) Close

6) Close

7) Close

8) Close

9) Open to Mashtun

10) Open

Mashing - Pump 1 On Rims on when temp needs to be raised

1) Close

2) Open

3) Close

4) Open

5) Close

6) Open - Bypass loop

7) Close

8) Open - Bypass loop

9) Open to Mashtun

10) Open part way to keep 1/2" wort above grain.

Transfer 1st Runnings

1) Close

2) Open

3) Close

4) Open

5) Close

6) Close

7) Close

8) Close

9) Open to Kettle

10) Open Full

Batch Sparge (same as fill mashtun process)

Transfer 2nd Runnings (same as Transfer 1st Runnings)

Whirlpool - Pumps 1 & 2 on

1) Close

2) Close

3) Open

4) Open

5) Open

6) Close

7) Close

8) Close

9) Open to Kettle

10) Open Full

Transfer to Chiller - all wort in system drained from 6 & 8 for starter or add to the batch.

1) Close

2) Close

3) Open

4) Open

5) Open

6) Close

7) Open

8) Close

9) Open to Kettle

10) Close

What do you guys think?