bakins

Well-Known Member

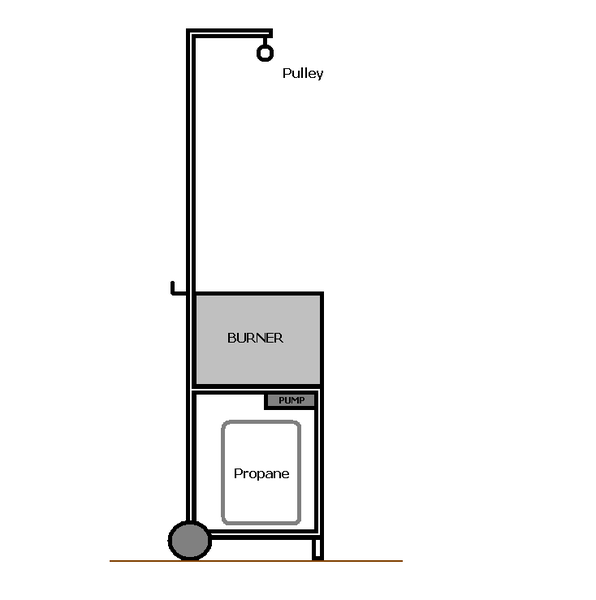

I think I am leaning toward part duex just for the cool factor. For an easy and pretty cheap upgrade, you could add a pump and a PID for a RIMS... wow, this could be epic.

Yeah, just pump from bottom back to the top of the kettle with the PID controlling the element.

For the bag lift, use a handwinch and a pulley.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)