Over the past few years I've made friends with the head brewer/co-owner of a local brewery. Sometimes I bring in some bottles of HB for feedback. One in particular that he liked was a Grodziskie I brewed 2 summers ago.

This summer, he asked if I wanted to do an autumn pro/am brew at the brewery after they finish their run of O-fest, and he made it clear he wanted to do that Grodziskie. He's been intrigued with the style and thinks it would be a good seller. He wanted a tweak: bump it up in ABV, as he doesn't think a 3% beer would sell. Apparently, he's not too risk-averse, as this is kind of a niche style. However, he thinks it will sit well for a refreshing autumn beer, especially if it's not too smoky like a rauchbier.

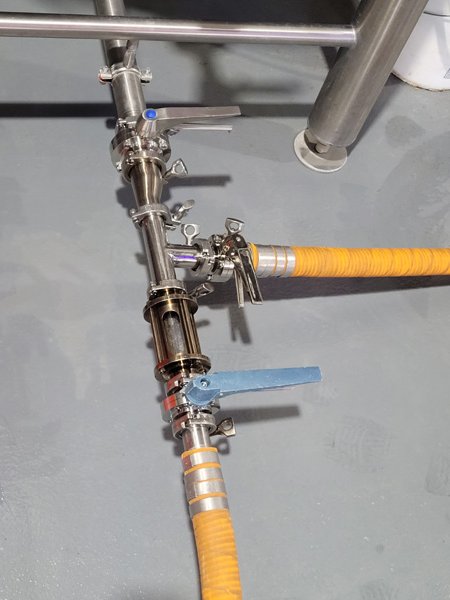

In August, I brewed a 5-gal test batch, and brought some bottles in for him and his coworkers to try last week. It is 5.1% ABV, so more in line with the strength he's looking for. He liked the test batch and wants to move forward on this! This is a 15 bbl brewery, so in mid-late Oct we will brew 450-ish gallons of smoked wheat beer. I get to come in for the entire brew day--something like 7 or 8 hours. I'll probably be lugging some sacks of grain, etc. But I'm excited to learn about how a real brewery works, first-hand, as I have never done this before.

Then the brewery will do a roll out, probably early Nov, so it will be fun to be there for the unveiling of this brew. AFAIK, no one has brewed a Grodziskie/Graetzer in this area. We have to brainstorm a way to promote it. He asked me to think of a name. They like to do pop music references for some of their beer names so I thought of "Smoke From a Distant Fire." (The song was a one-hit wonder. Hopefully, the beer won't be.) Maybe someone here has an idea for a name...I'm open to suggestions.

My recipe is not true-to-form for a historical Grodziskie. Per the style it's all Weyermann oak-smoked wheat, with a little acid malt for pH adjustment. But I bittered with Perle, and pitched US-05. He liked the flavor and aroma, but thought that it may need a bit of color, so we could add a little melanoidin or toasted wheat.

This summer, he asked if I wanted to do an autumn pro/am brew at the brewery after they finish their run of O-fest, and he made it clear he wanted to do that Grodziskie. He's been intrigued with the style and thinks it would be a good seller. He wanted a tweak: bump it up in ABV, as he doesn't think a 3% beer would sell. Apparently, he's not too risk-averse, as this is kind of a niche style. However, he thinks it will sit well for a refreshing autumn beer, especially if it's not too smoky like a rauchbier.

In August, I brewed a 5-gal test batch, and brought some bottles in for him and his coworkers to try last week. It is 5.1% ABV, so more in line with the strength he's looking for. He liked the test batch and wants to move forward on this! This is a 15 bbl brewery, so in mid-late Oct we will brew 450-ish gallons of smoked wheat beer. I get to come in for the entire brew day--something like 7 or 8 hours. I'll probably be lugging some sacks of grain, etc. But I'm excited to learn about how a real brewery works, first-hand, as I have never done this before.

Then the brewery will do a roll out, probably early Nov, so it will be fun to be there for the unveiling of this brew. AFAIK, no one has brewed a Grodziskie/Graetzer in this area. We have to brainstorm a way to promote it. He asked me to think of a name. They like to do pop music references for some of their beer names so I thought of "Smoke From a Distant Fire." (The song was a one-hit wonder. Hopefully, the beer won't be.) Maybe someone here has an idea for a name...I'm open to suggestions.

My recipe is not true-to-form for a historical Grodziskie. Per the style it's all Weyermann oak-smoked wheat, with a little acid malt for pH adjustment. But I bittered with Perle, and pitched US-05. He liked the flavor and aroma, but thought that it may need a bit of color, so we could add a little melanoidin or toasted wheat.

Last edited: