DKHopGrowers

Member

- Joined

- Dec 19, 2013

- Messages

- 6

- Reaction score

- 0

First Off, thank you to all the great people on this forum. I am just finishing up a DIY single tier automated system and this is the first question that I have not been able to find the answer to through the search.

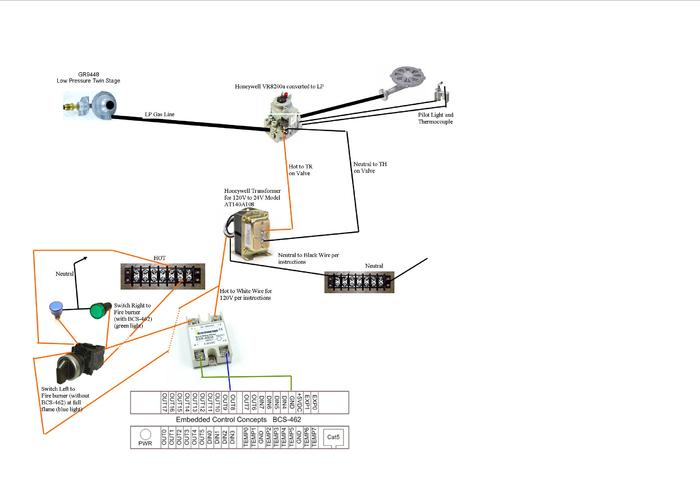

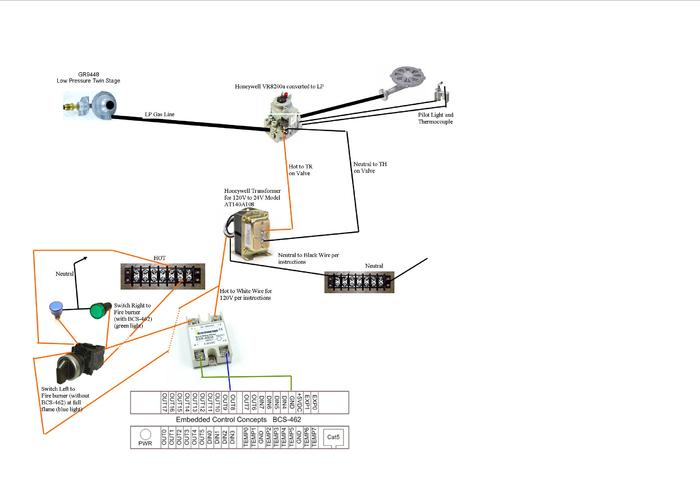

I am having some issues with my Honeywell VR8200a Valves (everything converted for Low Pressure LP). I believe it has to do with my wiring, please see simplified wiring diagram attached. I burnt up one of the 120v to 24v honeywell transformers tonight.

As you can see on the attached diagram, my goal is to click the switch to the left and the burner come on a full LP (ie Manual). I want to click the switch to the right and run the burner from my BCS-462 (ie Auto).

Problems: I get a click sound from the honeywells when I move the switch to the left (manual). Gas then starts being released however it is a very small amount (1/8" of blue flame out of the banjo burner and can not get more gas to push out of valve). Then, when I move the switch to the right (Auto Mode) and try to turn the honeywell on with my computer via the BCS it clicks the honeywell on and in under a second it turns right back off.

Any advice will be much appreciated. I also included the LP Valve info on the attachment and how I have the valves connected to the transformers to TH or TR on the valves.

Better Quality Diagram can be seen here: https://drive.google.com/file/d/0ByfSRTDKhqvya0s4ZEpiMlh6ZEE/edit?usp=sharing

Silas

I am having some issues with my Honeywell VR8200a Valves (everything converted for Low Pressure LP). I believe it has to do with my wiring, please see simplified wiring diagram attached. I burnt up one of the 120v to 24v honeywell transformers tonight.

As you can see on the attached diagram, my goal is to click the switch to the left and the burner come on a full LP (ie Manual). I want to click the switch to the right and run the burner from my BCS-462 (ie Auto).

Problems: I get a click sound from the honeywells when I move the switch to the left (manual). Gas then starts being released however it is a very small amount (1/8" of blue flame out of the banjo burner and can not get more gas to push out of valve). Then, when I move the switch to the right (Auto Mode) and try to turn the honeywell on with my computer via the BCS it clicks the honeywell on and in under a second it turns right back off.

Any advice will be much appreciated. I also included the LP Valve info on the attachment and how I have the valves connected to the transformers to TH or TR on the valves.

Better Quality Diagram can be seen here: https://drive.google.com/file/d/0ByfSRTDKhqvya0s4ZEpiMlh6ZEE/edit?usp=sharing

Silas

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)