weathejx

Well-Known Member

I've been perusing the forums, checked out Kal's site, some instructables, etc. I think I have a pretty solid plan that I want to run by the experts and make sure I'm not crazy. I also need some help with the electrical, seeing as my experience there is limited to minor projects, simple house wiring, etc. I also have no skills with sketch-up, so I'm working with Paint :rockin:

I've been doing all grain for a year or so, but we moved into a condo, so I have no space for all my gear. Also, I only have an electric stove, so going eBIAB seems like the way to go. I'm planing on recirculating the mash, but I haven't done that before, so a lot of this is going to be new to me.

The goal is to end up with something like this: High Gravity BIAB, but with some more control over things (and shiny stuff), without the SWMBO killing me.

A few questions:

1. I was looking at MoreBeer's Ultimate Sparge Arm, which looks super cool, but I've never recirculated before, so I dont know if that's any better (or necessary) than a sprayer or another type of sparge arm. Or should I just try to whirlpool it with an angled pickup/outlet?

2. I have what I'm calling a "Temperature Tee" which is a stainless steel tee with a temp probe in the middle with camlocks on the ends. I plan on using this to get the temp of the mash at the point of recirculation, rather than down by the element. I was also going to use it on the outlet of my plate chiller. Is this overkill and/or stupid?

3. I'm planning on using the E-Stop switch as an on/off switch. I don't see the point of having an on/off and an e-stop. And I like the e-stop because it looks cool :cross: - any problems with this?

4. GFI. Yes, I realize that this is important and should be implemented (but I haven't designed that yet). It looks like the cheapest and most popular route is to use a spa panel. Is there anything stopping me from buying a 240v GFI breaker and installing it directly in my tool box? If I can do that, I assume it should be the first thing the power touches in the box.

I think that's all I can think of right now. Please let me know what you think, where I've messed up, etc.

EDIT: Added better images, removed crappy ones, using my equipment list.

This is the album of my designs.

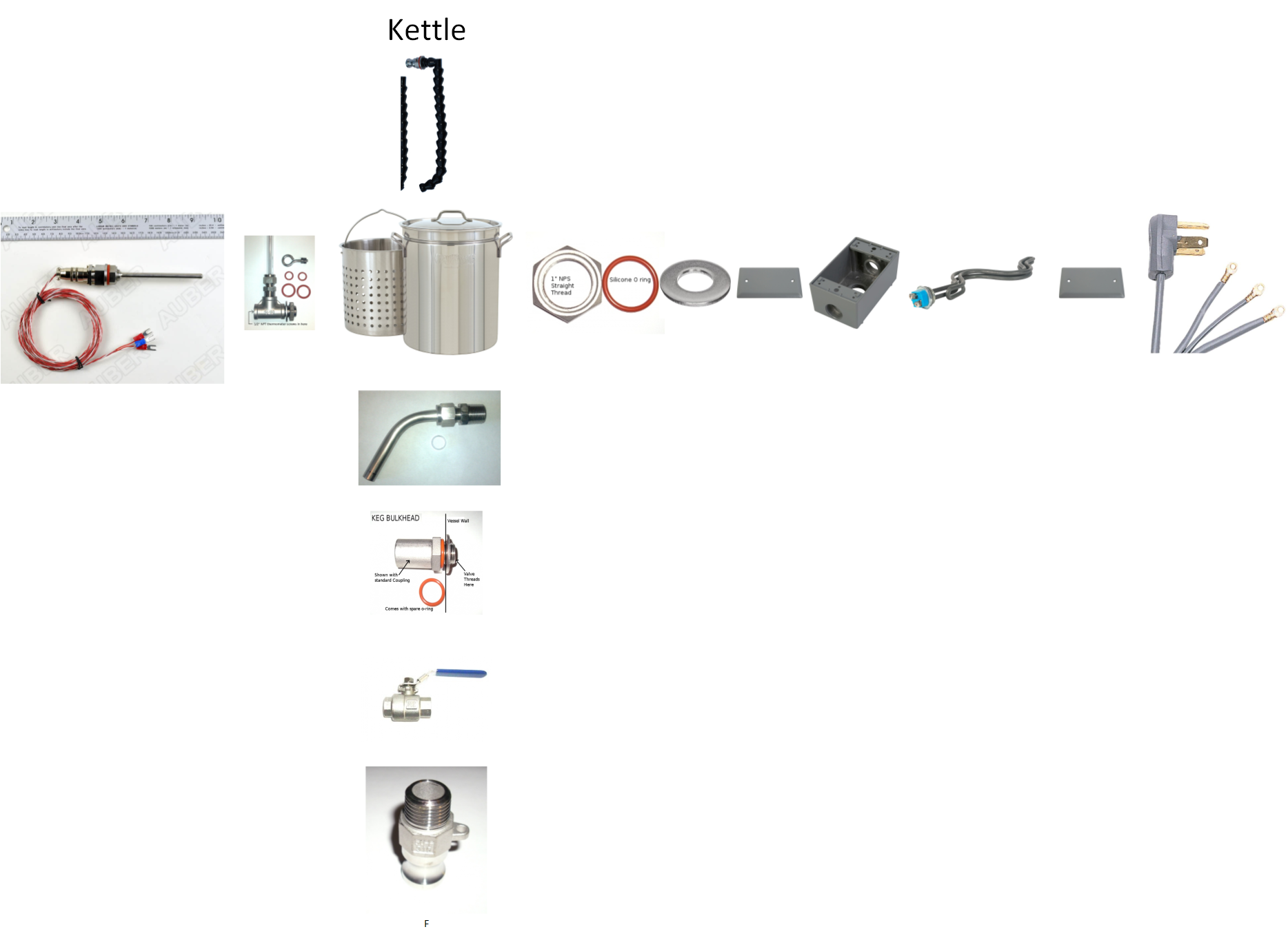

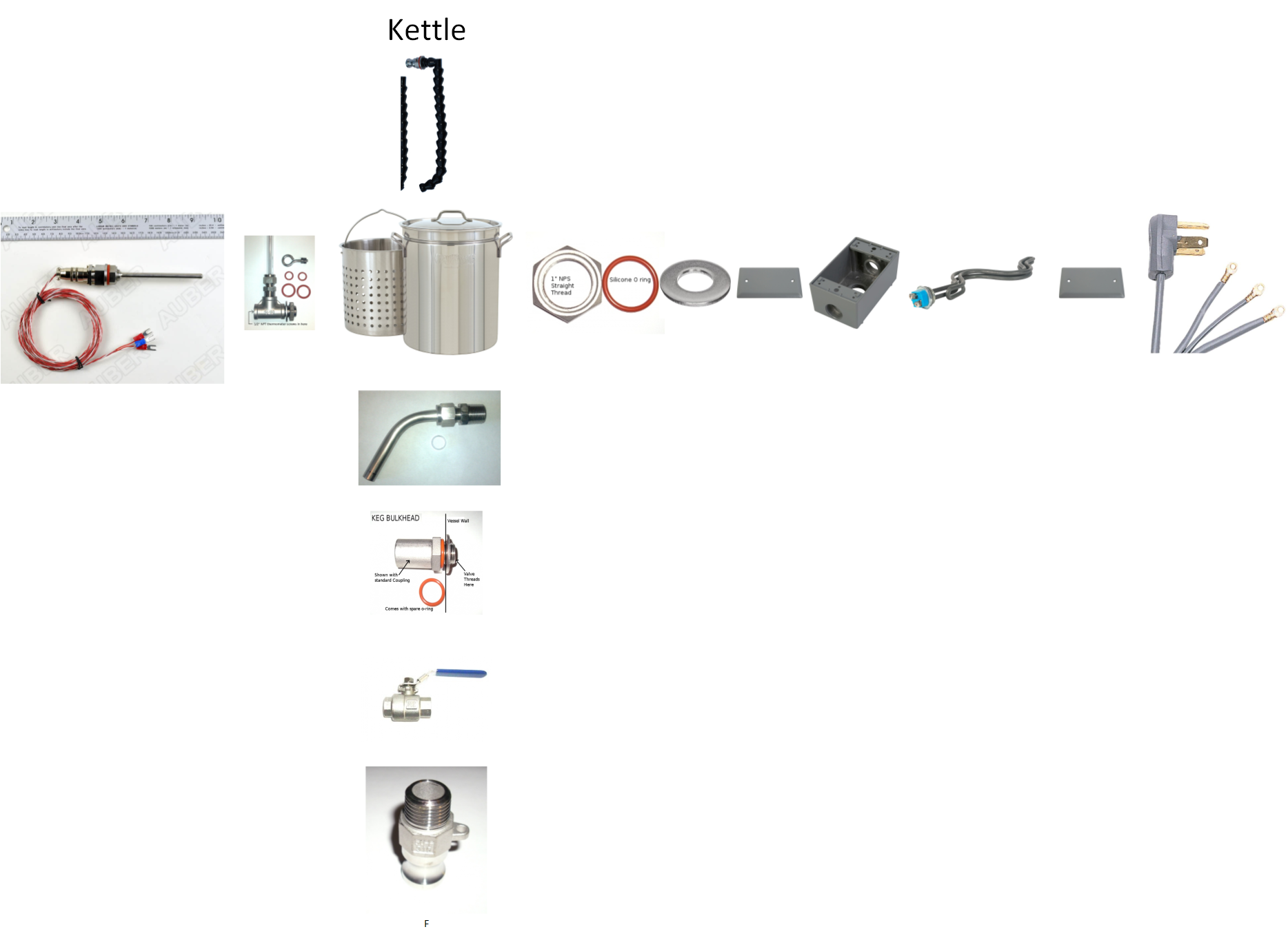

Kettle Design:

Transfer Design:

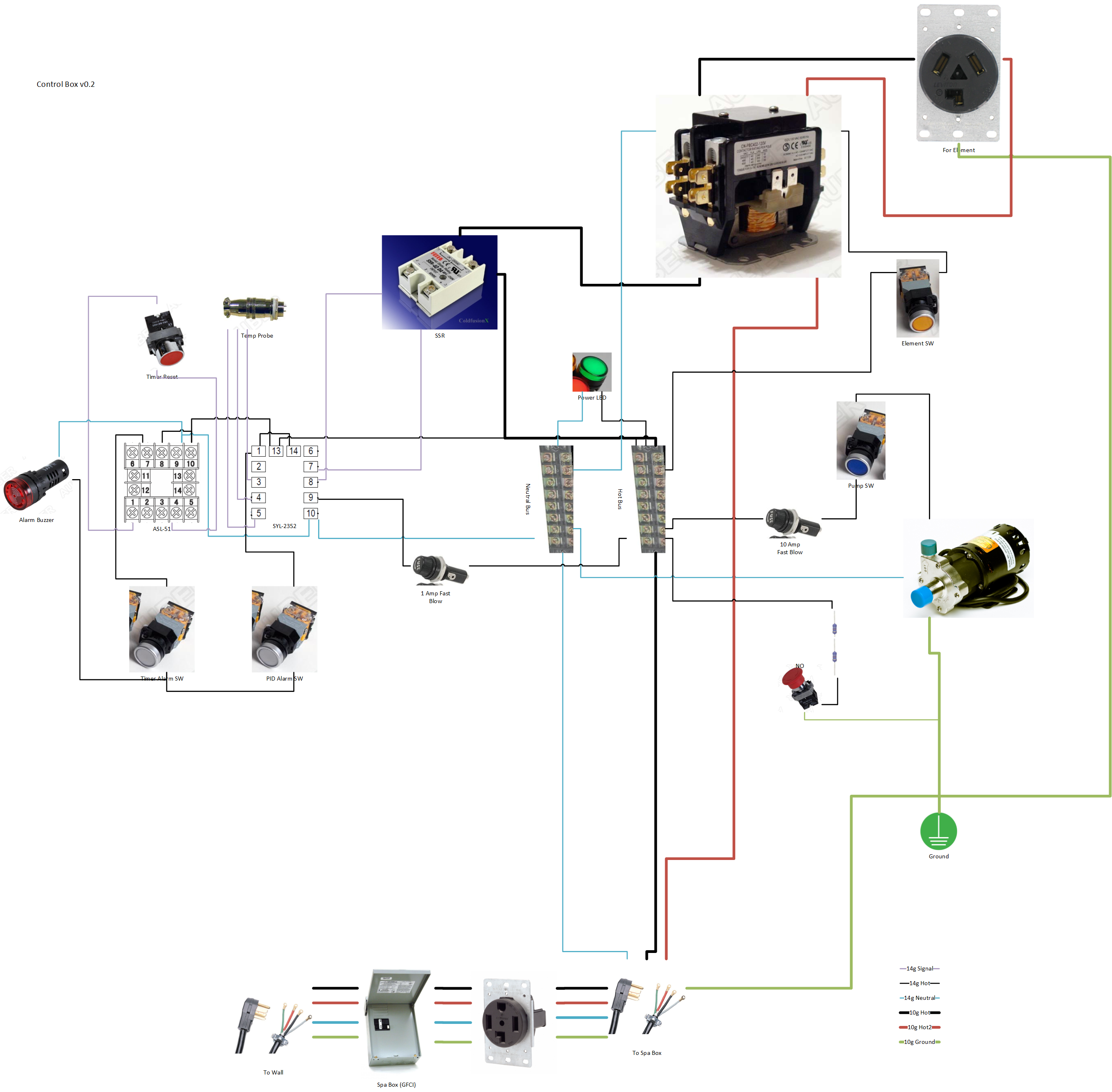

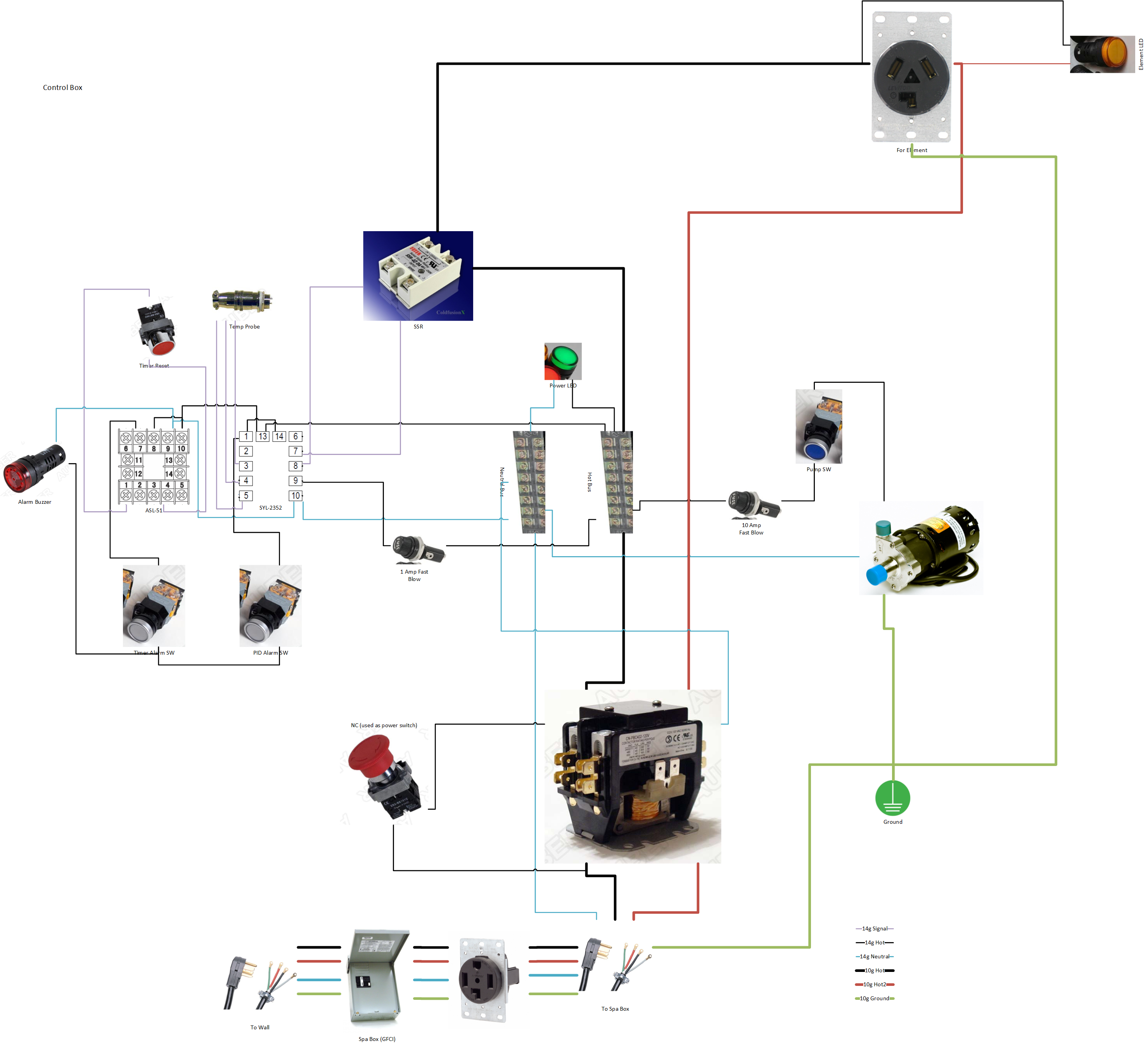

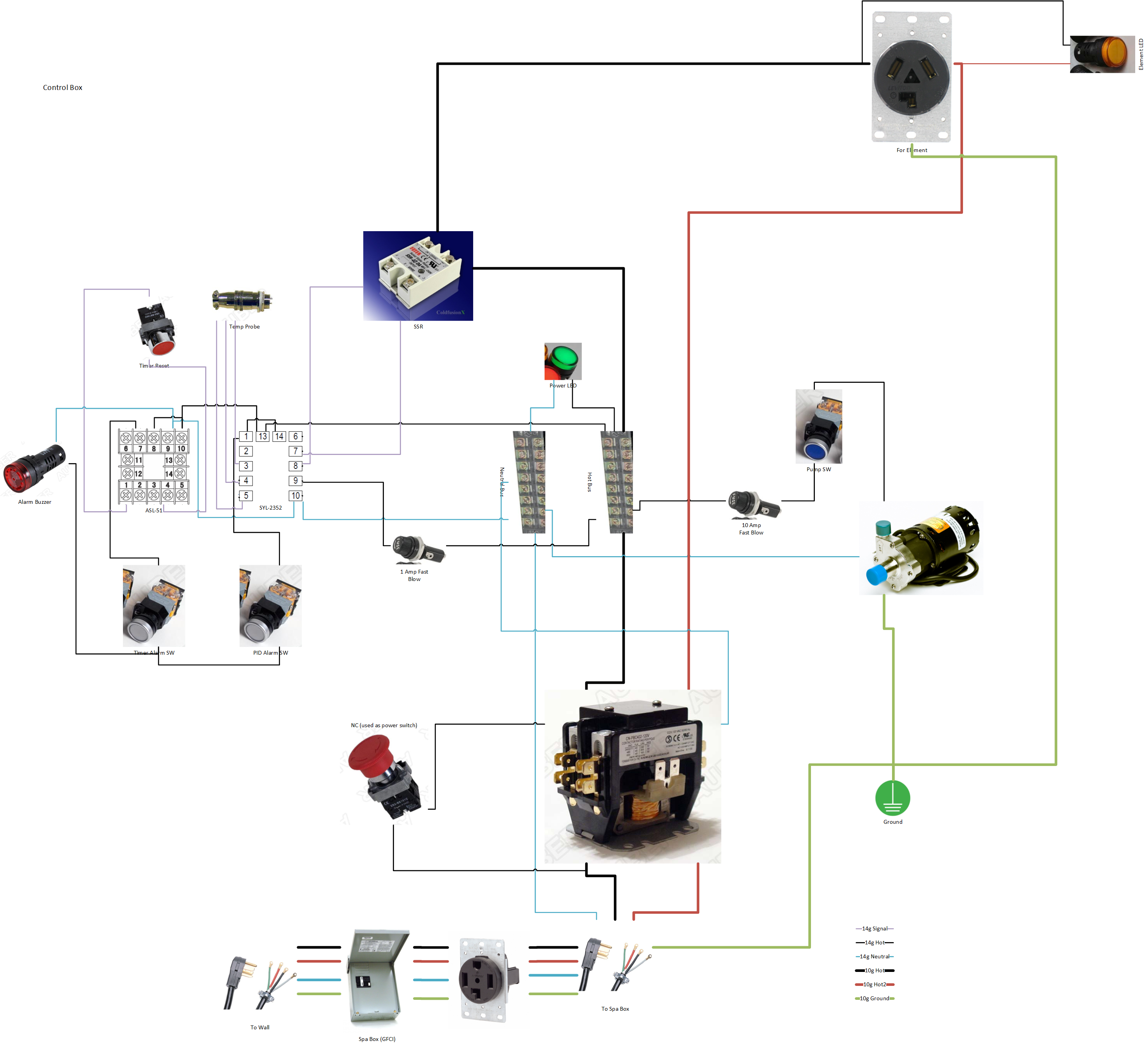

Control Box Wiring:

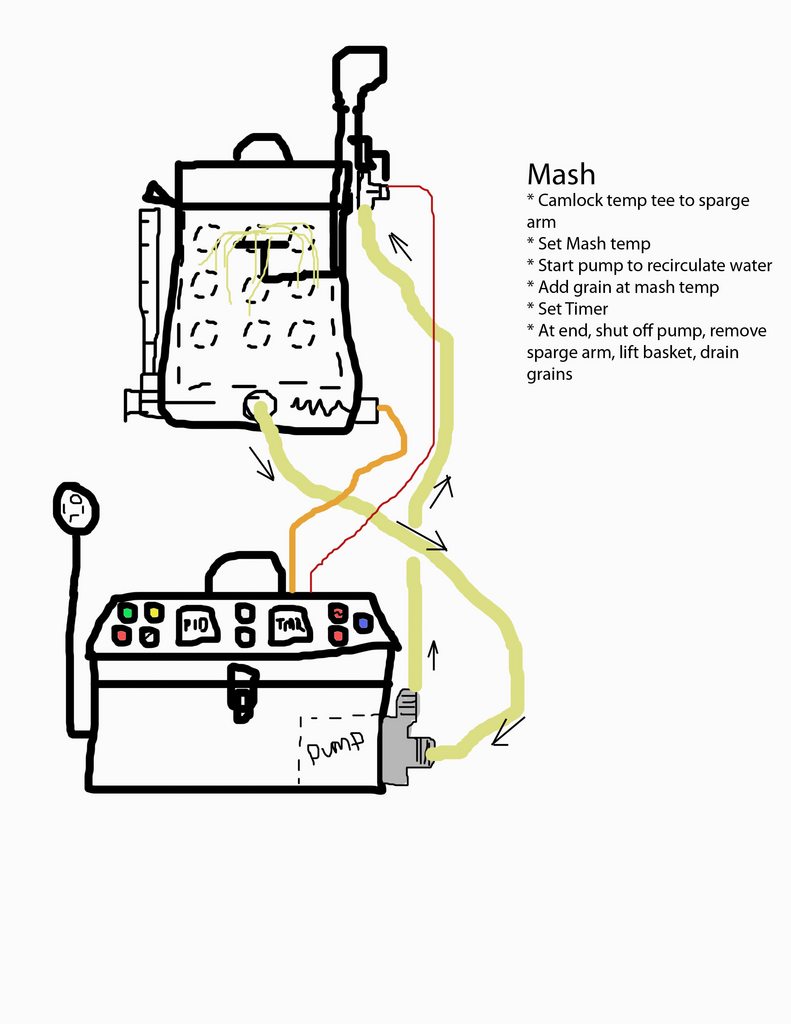

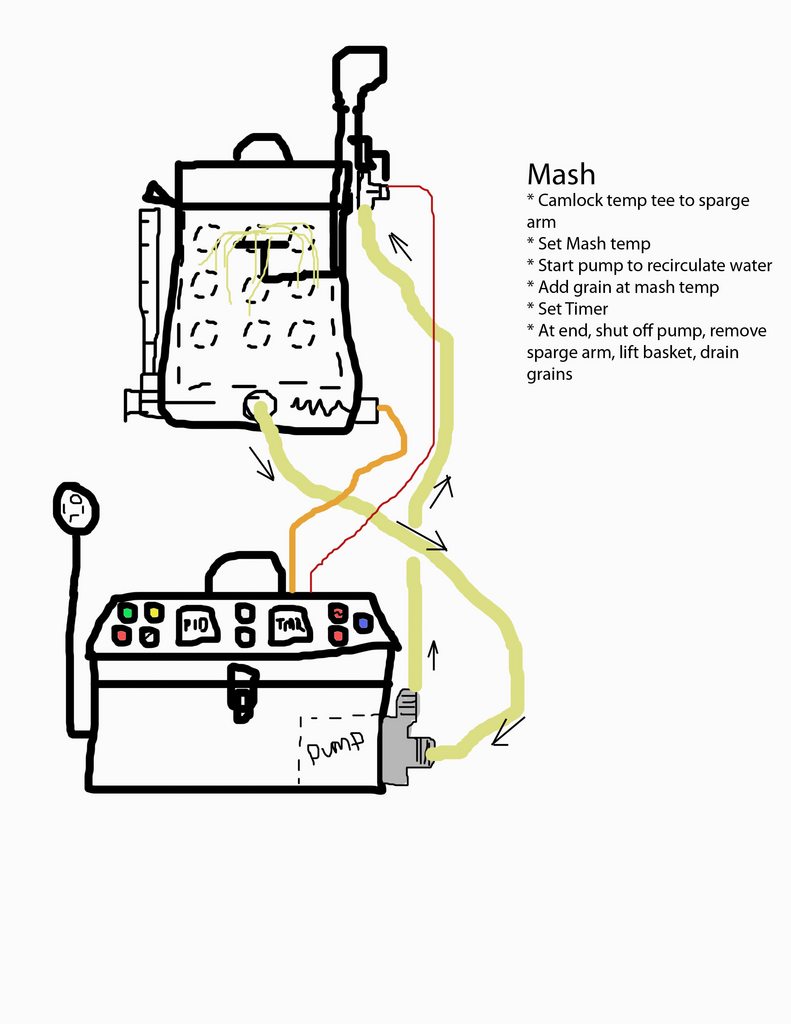

Mash:

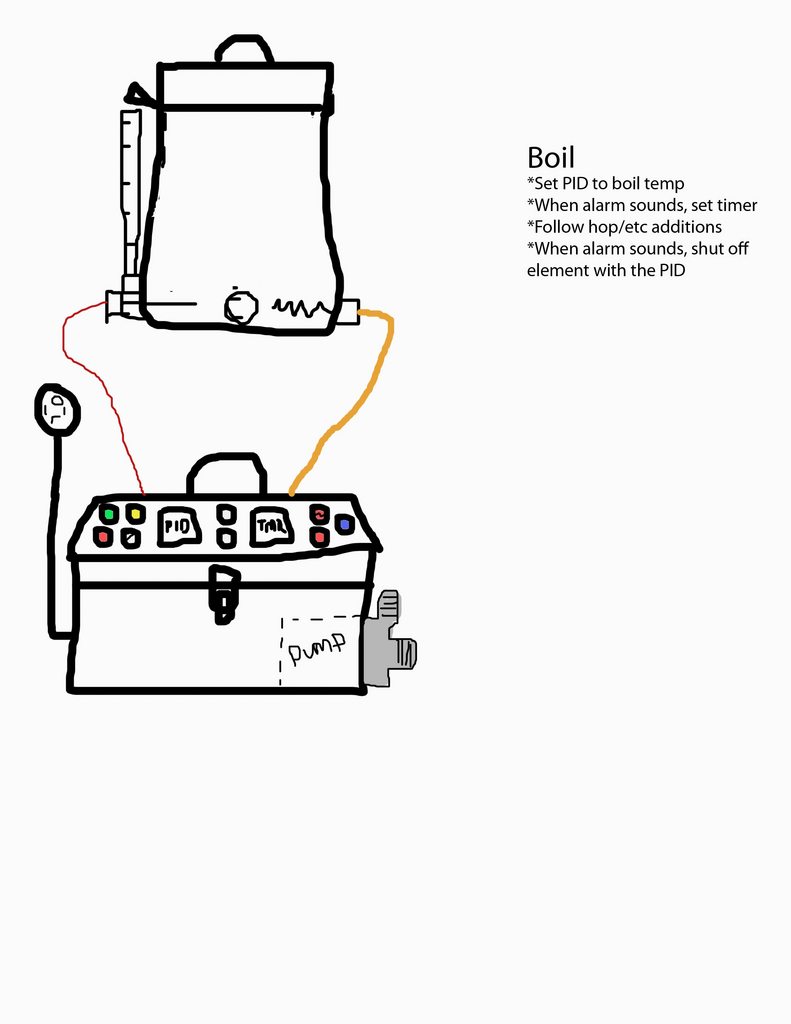

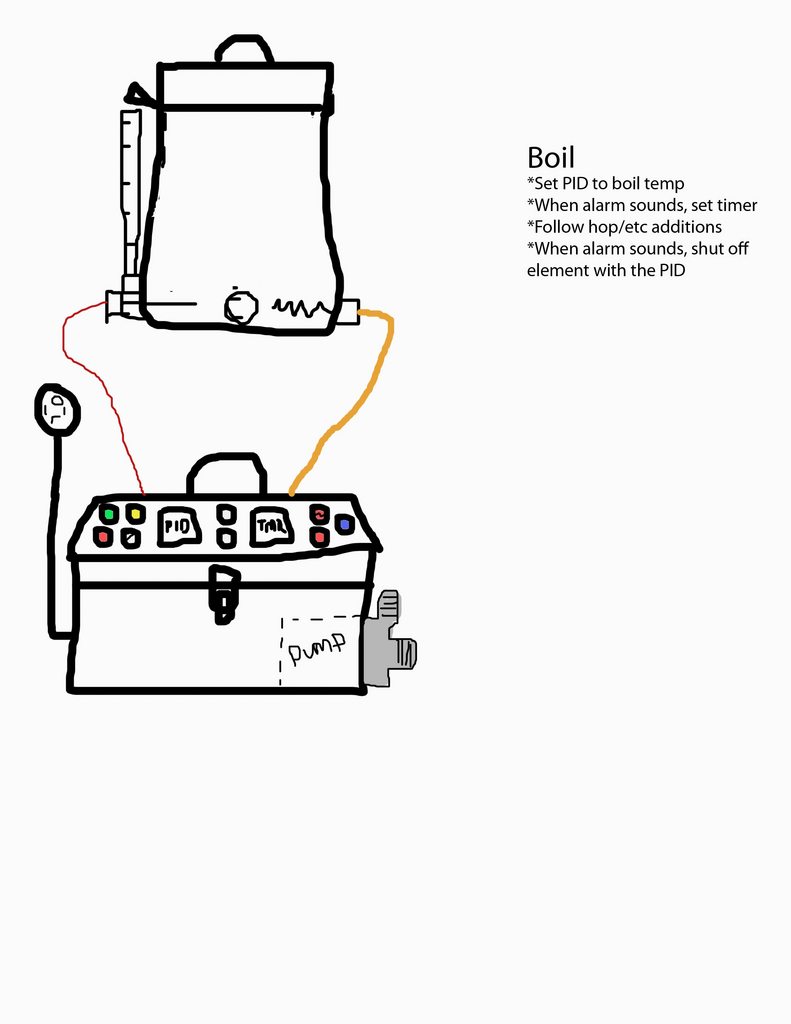

Boil:

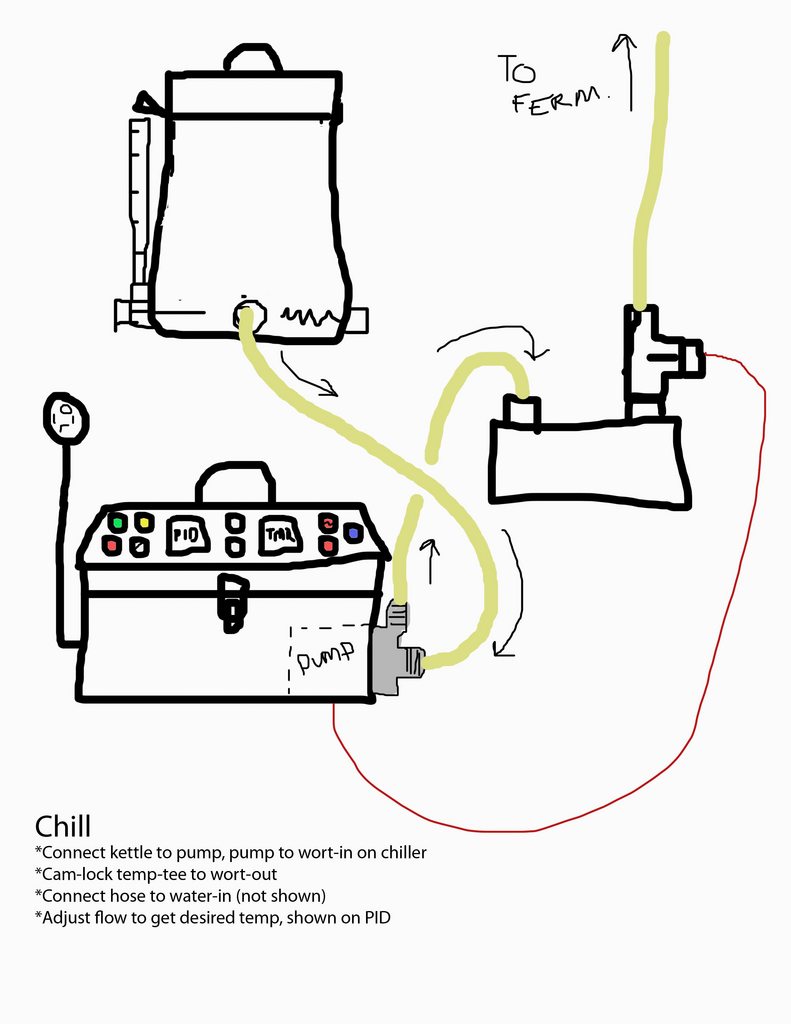

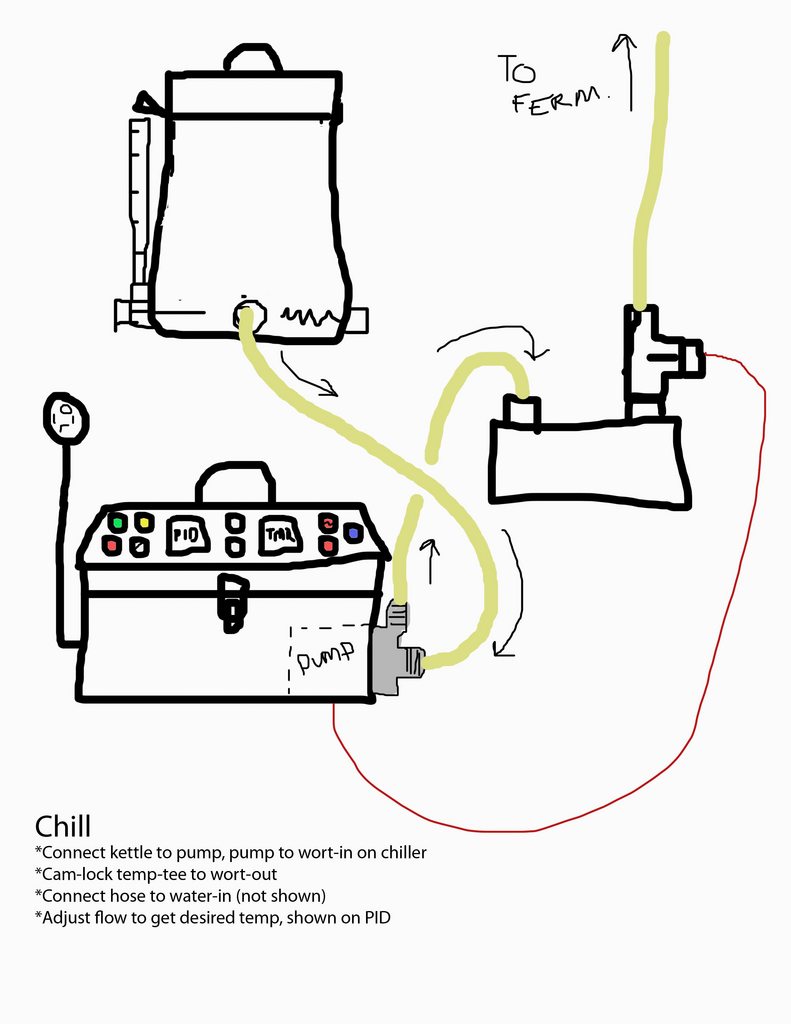

Chill:

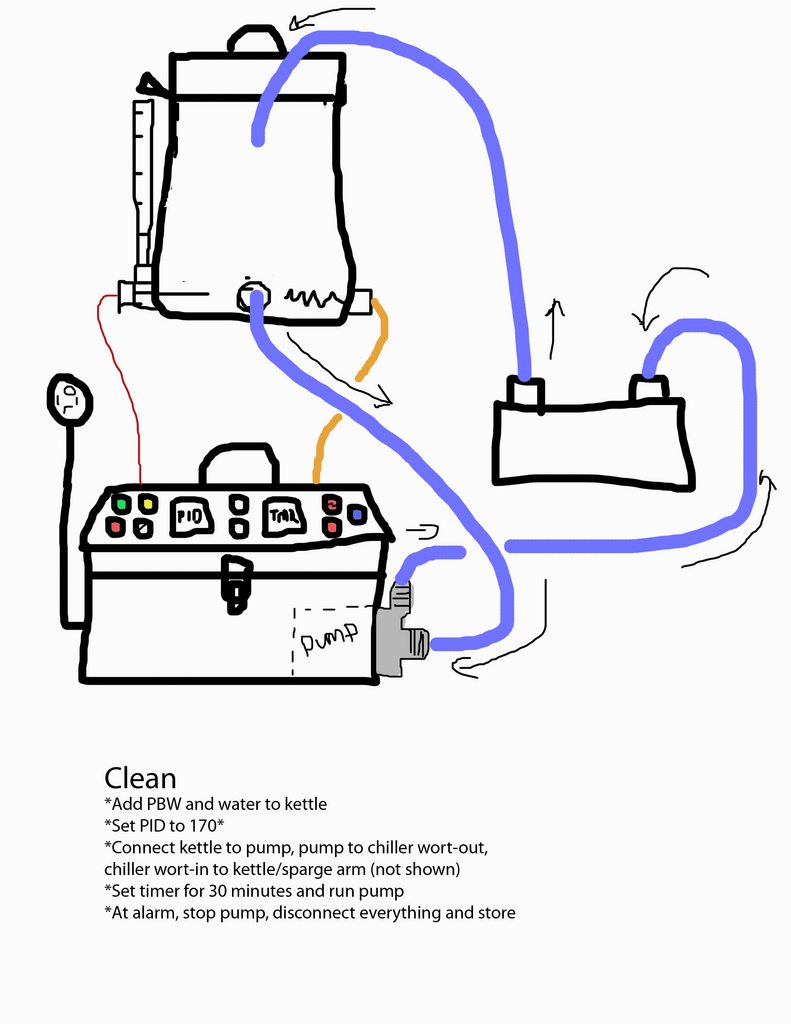

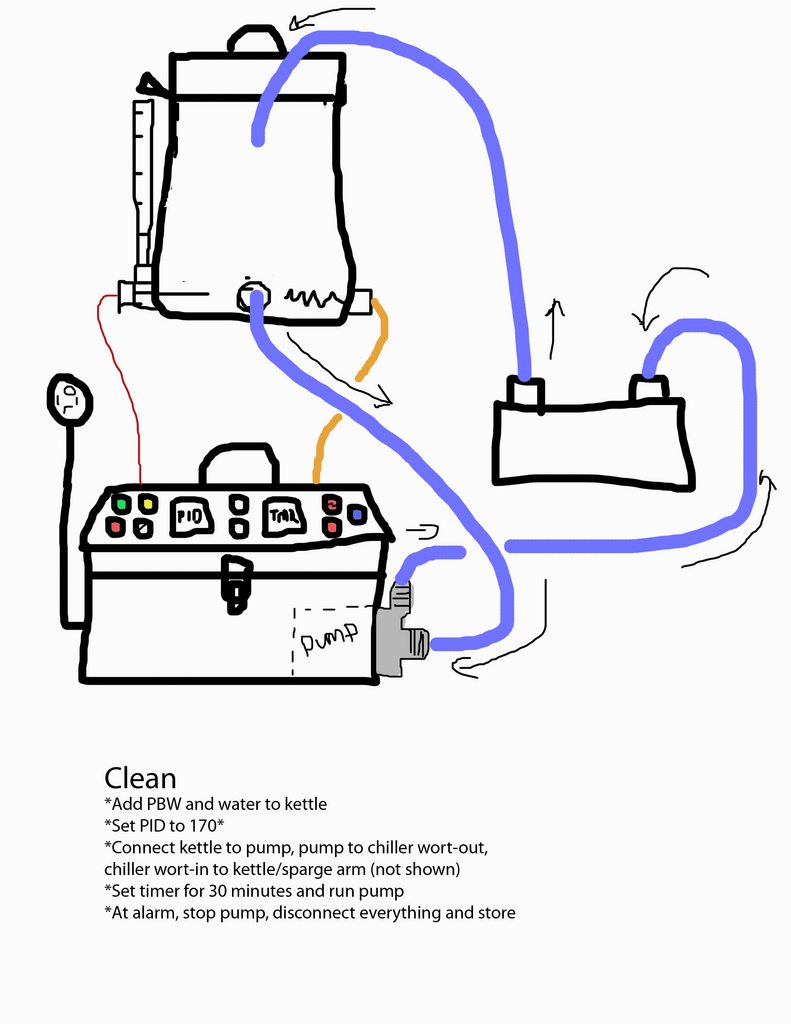

Clean:

I've been doing all grain for a year or so, but we moved into a condo, so I have no space for all my gear. Also, I only have an electric stove, so going eBIAB seems like the way to go. I'm planing on recirculating the mash, but I haven't done that before, so a lot of this is going to be new to me.

The goal is to end up with something like this: High Gravity BIAB, but with some more control over things (and shiny stuff), without the SWMBO killing me.

A few questions:

1. I was looking at MoreBeer's Ultimate Sparge Arm, which looks super cool, but I've never recirculated before, so I dont know if that's any better (or necessary) than a sprayer or another type of sparge arm. Or should I just try to whirlpool it with an angled pickup/outlet?

2. I have what I'm calling a "Temperature Tee" which is a stainless steel tee with a temp probe in the middle with camlocks on the ends. I plan on using this to get the temp of the mash at the point of recirculation, rather than down by the element. I was also going to use it on the outlet of my plate chiller. Is this overkill and/or stupid?

3. I'm planning on using the E-Stop switch as an on/off switch. I don't see the point of having an on/off and an e-stop. And I like the e-stop because it looks cool :cross: - any problems with this?

4. GFI. Yes, I realize that this is important and should be implemented (but I haven't designed that yet). It looks like the cheapest and most popular route is to use a spa panel. Is there anything stopping me from buying a 240v GFI breaker and installing it directly in my tool box? If I can do that, I assume it should be the first thing the power touches in the box.

I think that's all I can think of right now. Please let me know what you think, where I've messed up, etc.

EDIT: Added better images, removed crappy ones, using my equipment list.

This is the album of my designs.

Kettle Design:

Transfer Design:

Control Box Wiring:

Mash:

Boil:

Chill:

Clean:

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)