Speaking of helping Zymatic users...if you are having repeated FE #1 while attempting to start your brew, I have come up with a recipe fix for that. Over the last 5 or 6 brews I have been testing a theory and it seems to be working.

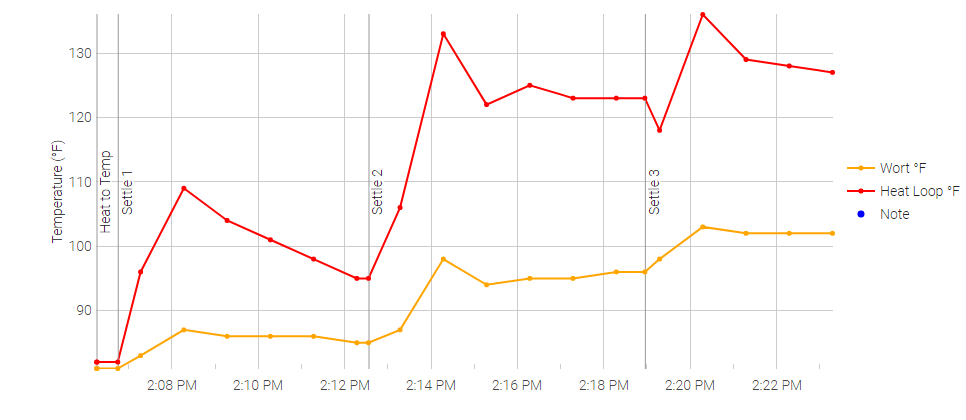

As the Zymatic gets older, mine is a circa 2016 unit, the HEX loop and the brew pump begin to operate inefficiently. The system just can't handle trying to go from 70 F degree water to 102 F degree water without overramping the HEX element and throwing the infamous Fatal Error #1.

Hey Mike, I have read your posts with interest. Maybe we need a new thread just for this kind of stuff?? This discussion is likely just causing confusion with the masses. But that is just my 2 pennies. FWIW I am open to discussion, but I have no desire to argue about this, I don't need to be right, and I don't want to get into the middle of any user/PICO drama with one user (not you) in particular. I am just sharing my thoughts.

"Hex Loop and brew pump beginning to operate inefficiently." Hmmm, really? An inefficient brew pump is easily replaced, but I question how this would actually happen on a large scale and be a wide spread problem. Wearing out a pump like this would be irregular. Regarding the heat exchanger efficiency, well that is pretty straight fwd physics of thermal equilibrium. The only logical ways to have the spike version of Fault #1 happen that I can see are:

1) the heating element no longer functions properly. But this would likely result in less of a spike not more. But in the end it should be an easy diagnosis and/or replacement. But again, because of the spike we are talking about that causes Fault #1, I do not see this as the problem.

2) Not enough liquid to dissipate the heat from the exchanger causing a abnormal rise in the temperature of the heat loop. This would be caused by inefficient flow though the wort pump. See my thoughts on pump efficiency above. If this actually was the case I would expect it to be caused by air leaks in the intake line or blockages and not with the pump itself. Simply removing the ball locks and and keg from the equation is the easy test here and removes most all the variables. Just put the open ended black line into a bucket of water instead of connecting it to a keg, and run the cycle. Your case may be different, but again in general, I just don't think it is a problem with the pump itself.

3) a physical barrier slowing/not allowing the natural thermal equilibrium process to take place. Thus, the heat transfer does not take place like it is suppose to and the heat loop gets too hot and boom, fault #1. This is likely the problem for anyone having this issue. You may be different.

I had the same problem, and in the end it was #3 with a caramelized buildup preventing heat transfer. It took some 15 plus cleaning cycles (14 of which failed Fault #1) and several days to solve it. I only got it to work with creative hot water additions, quickly switching between v1 and v6 cleaning cycles, quickly re running the cycles and skipping steps to get back to where I was, and wrapping the keg to reduce heat loss. Again one has to quickly repeat the cycles to keep the temperature up. Eventually it will get though the V6 cleaning cycle. Once it was complete, I did it again, and it worked beginning to end. I then ran it through the (more difficult heating cycle of) the standard cleaning cycle and it worked as well. I then heated an imaginary beer up from dead cold and it worked as well. I expect (not trying to sound like Kevin) that it will be, for the majority of users, a barrier problem/cleaning issue.

The end story here for me is that is NOT a mechanical Zymatic issue, it is a cleaning issue. Better cleaning cycles provided by PICO, and better more regular cleaning by the operator will go a long way to solve the issue in the long term for any folks who may suffer from this issue.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)