kenglish427

Member

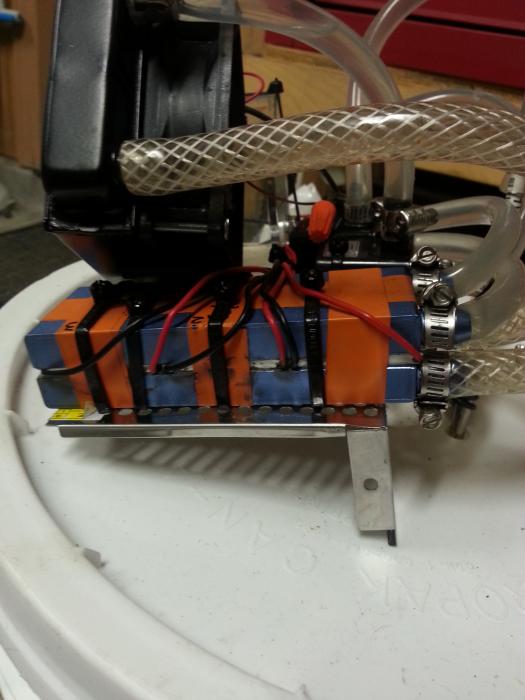

Im working on building a Fermentation temp controller from a Peltier plate.

http://en.wikipedia.org/wiki/Thermoelectric_cooling

Ive got a pretty simple design thought up to place the plate between a heat-sink and fan on the hot side, and a water plate on the cold side, and a small dc pump to circulate a coolant liquid submersed in a plastic fermenter. Has anyone ever tried something like this? I bought all the materials for less than $150 from various websites and it just seems like a good concept for space saving, it should all fut on top of the fermenter lid( too much brew equipment in the garage to fit a second freezer) and its power consumption will be roughly 1 Amp at 120Volts AC. so power consumption will be much better than any other option Ive found.

Let me know what yalls thoughts are.

http://en.wikipedia.org/wiki/Thermoelectric_cooling

Ive got a pretty simple design thought up to place the plate between a heat-sink and fan on the hot side, and a water plate on the cold side, and a small dc pump to circulate a coolant liquid submersed in a plastic fermenter. Has anyone ever tried something like this? I bought all the materials for less than $150 from various websites and it just seems like a good concept for space saving, it should all fut on top of the fermenter lid( too much brew equipment in the garage to fit a second freezer) and its power consumption will be roughly 1 Amp at 120Volts AC. so power consumption will be much better than any other option Ive found.

Let me know what yalls thoughts are.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)