givagodamazio

Member

- Joined

- Apr 20, 2020

- Messages

- 9

- Reaction score

- 1

Hi!

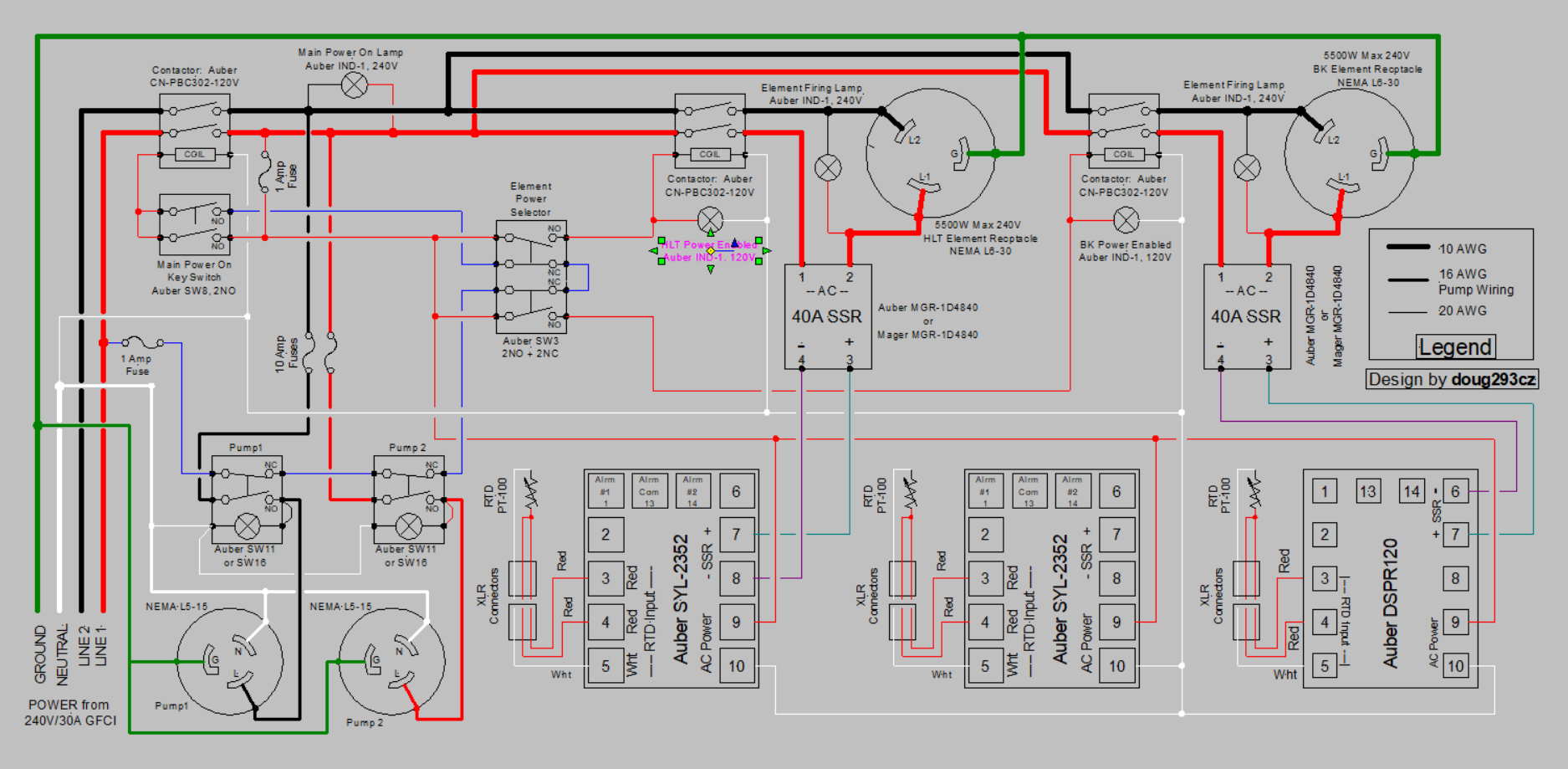

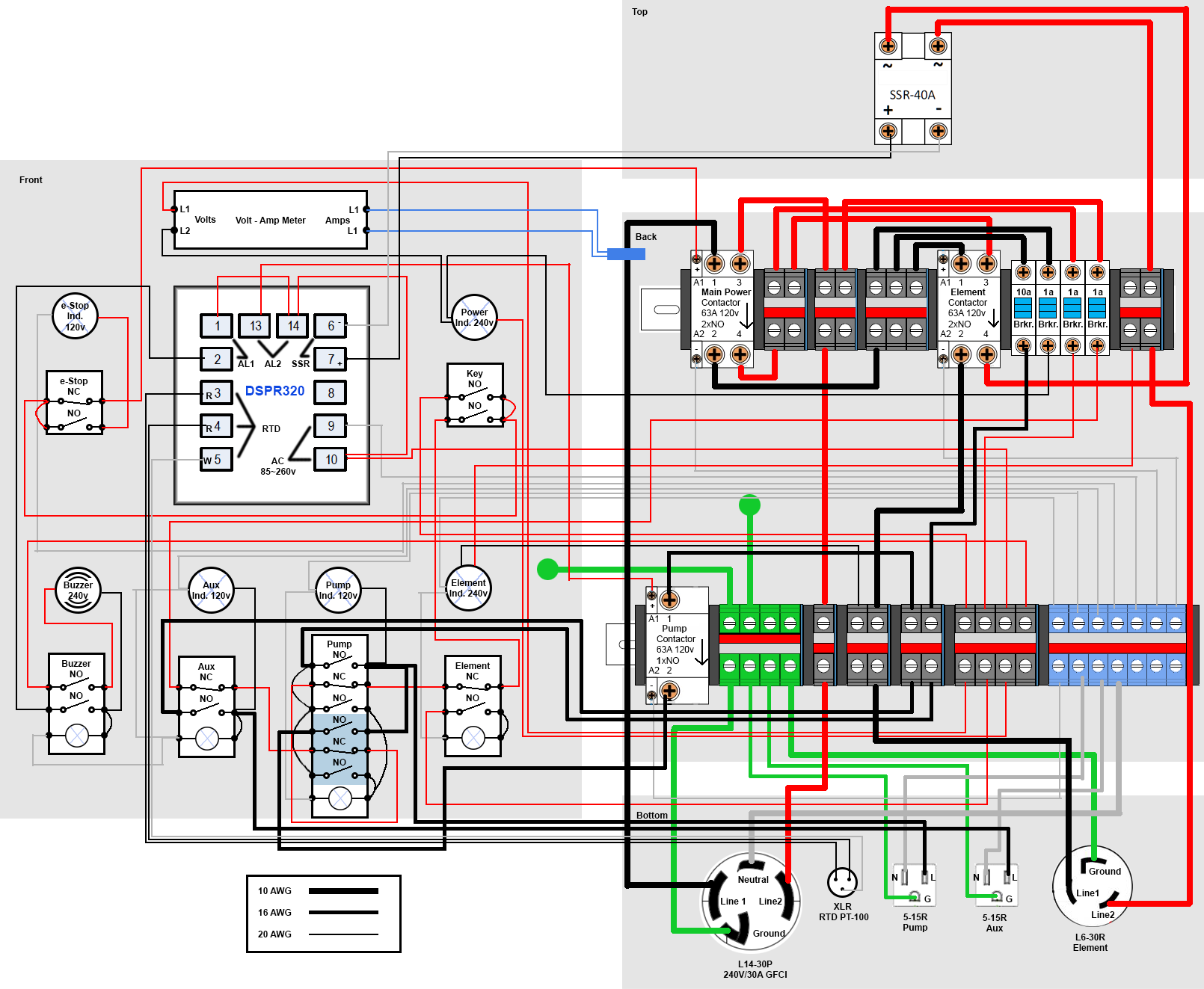

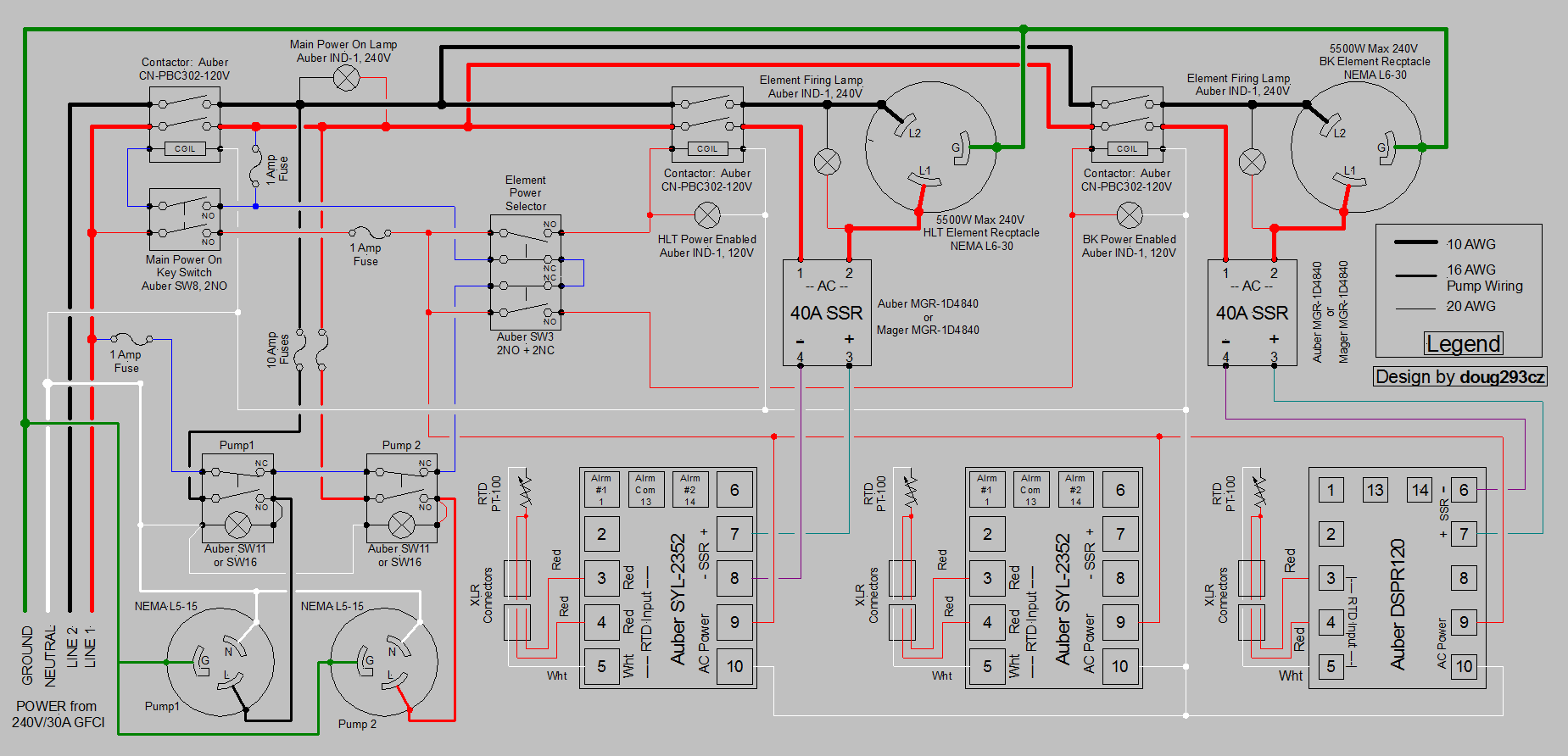

I am creating the wiring diagram of my new eBIAB panel (95% based on existing diagrams from this forum : )and it's all going good, except for one part that is burning my head.

)and it's all going good, except for one part that is burning my head.

The system will have the EZBoil DSPR320 so I want to take profit of it's automatic pump control option.

I was thinking to have my pump switch with 3 positions, On / Auto / Off. I wanted to include the safe start loop designed by Doug293cz, but all switches that I found have to NO blocks and a off position, but no NC block for the safe start.

I could add a NC block but will that work? Won't it be NC for a specific position only, I mean, NC will be close only when On is open.

Any help will count.

Thank you so much!

I will post diagrams here when they are ready.

Cheers!

I am creating the wiring diagram of my new eBIAB panel (95% based on existing diagrams from this forum :

The system will have the EZBoil DSPR320 so I want to take profit of it's automatic pump control option.

I was thinking to have my pump switch with 3 positions, On / Auto / Off. I wanted to include the safe start loop designed by Doug293cz, but all switches that I found have to NO blocks and a off position, but no NC block for the safe start.

I could add a NC block but will that work? Won't it be NC for a specific position only, I mean, NC will be close only when On is open.

Any help will count.

Thank you so much!

I will post diagrams here when they are ready.

Cheers!

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)