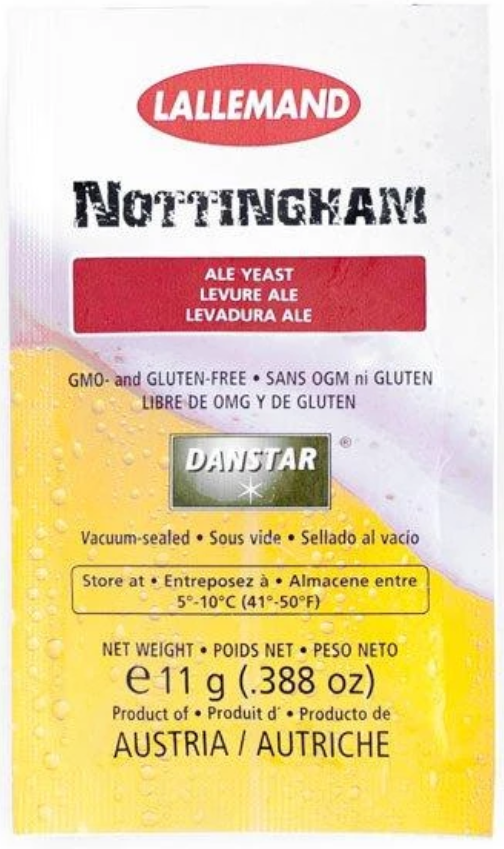

So I pitched two rehydrated packs in 12 gallons of wort with an og of 1.072 at 55 degrees on Sunday afternoon. Late Monday the ferm chamber had warmed it up to 68, and I had mild activity. Tuesday morning I checked the brew haus and the fermenter had puked about 1/2 gallon on the floor. I mopped up and installed a blow off. This pm the yeast is ripping!

Note to others, when using knottingham with high og wort, be prepared.

Eric

Note to others, when using knottingham with high og wort, be prepared.

Eric