bstacy1974

Well-Known Member

I should have asked for advice before brewing today, but oh well. Call it an experiment.

So, I have some old hops in the freezer. Some in excess of 6 years old. Purchased from YVH, then repacked in 1oz vacuum sealed bags.

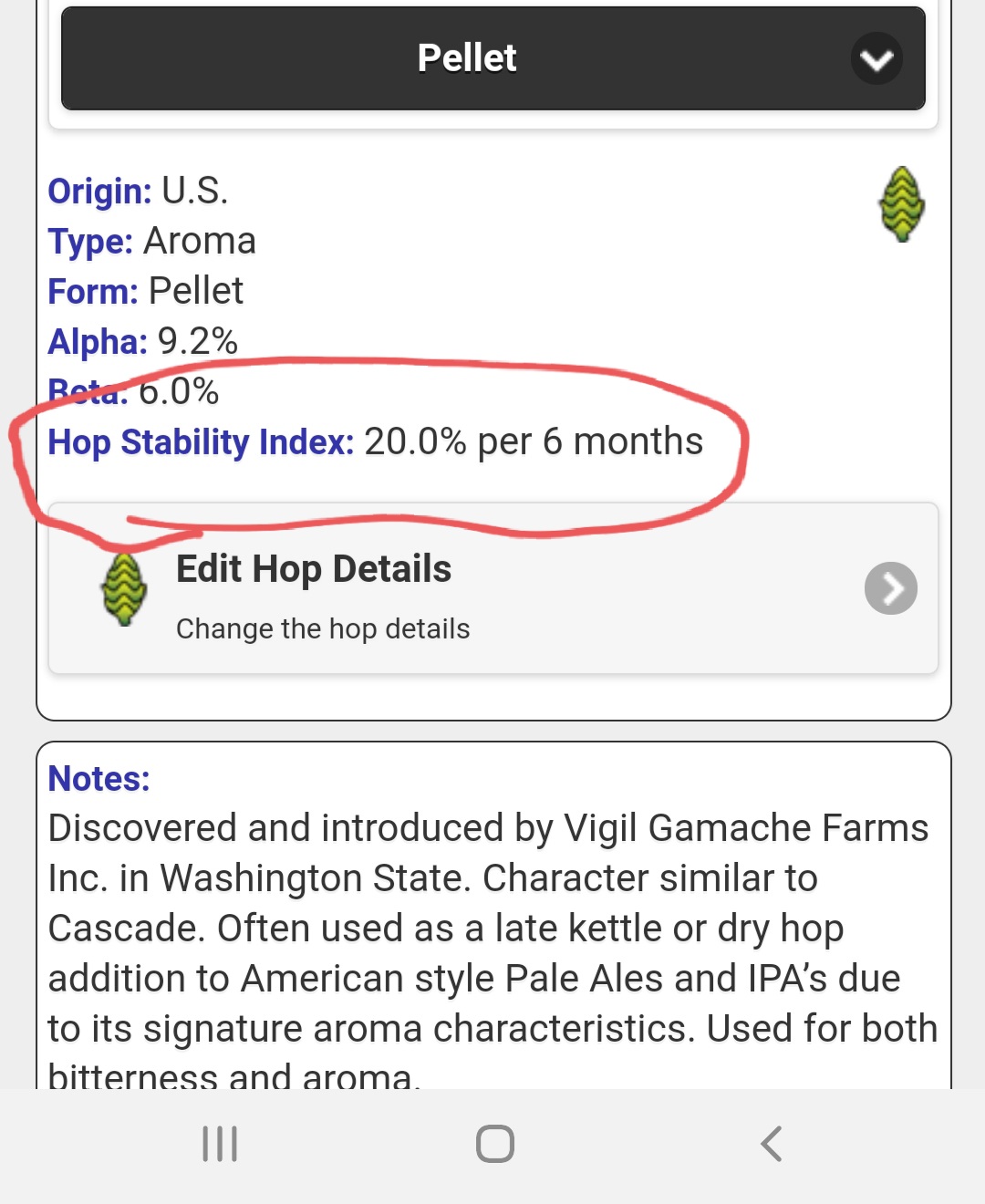

In an effort to clear my inventory, I decided to do a little research on how to utilize these ingredients. That's when I came across the Hop Stability Index or HSI. According to Beersmith, my 6 year old, 10%AA Centennial was estimated at 3.54%AA.

I ended up putting together a recipe using Centennial, Casade, and Mt Hood with the adjusted AA percentages.

13 ounces of hops had an estimated IBU of 60! There was a mountain of hops left in the kettle that forced me to leave behind a half gallon of wort.

So, has anyone else used the HSI in this way? What were your results?

So, I have some old hops in the freezer. Some in excess of 6 years old. Purchased from YVH, then repacked in 1oz vacuum sealed bags.

In an effort to clear my inventory, I decided to do a little research on how to utilize these ingredients. That's when I came across the Hop Stability Index or HSI. According to Beersmith, my 6 year old, 10%AA Centennial was estimated at 3.54%AA.

I ended up putting together a recipe using Centennial, Casade, and Mt Hood with the adjusted AA percentages.

13 ounces of hops had an estimated IBU of 60! There was a mountain of hops left in the kettle that forced me to leave behind a half gallon of wort.

So, has anyone else used the HSI in this way? What were your results?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)