Hi there,

This is my second all-grain batch in a row coming in short on my FG after fermentation has slowed. Here is the current recipe:

FG: 1.013

Target ABV: 5%

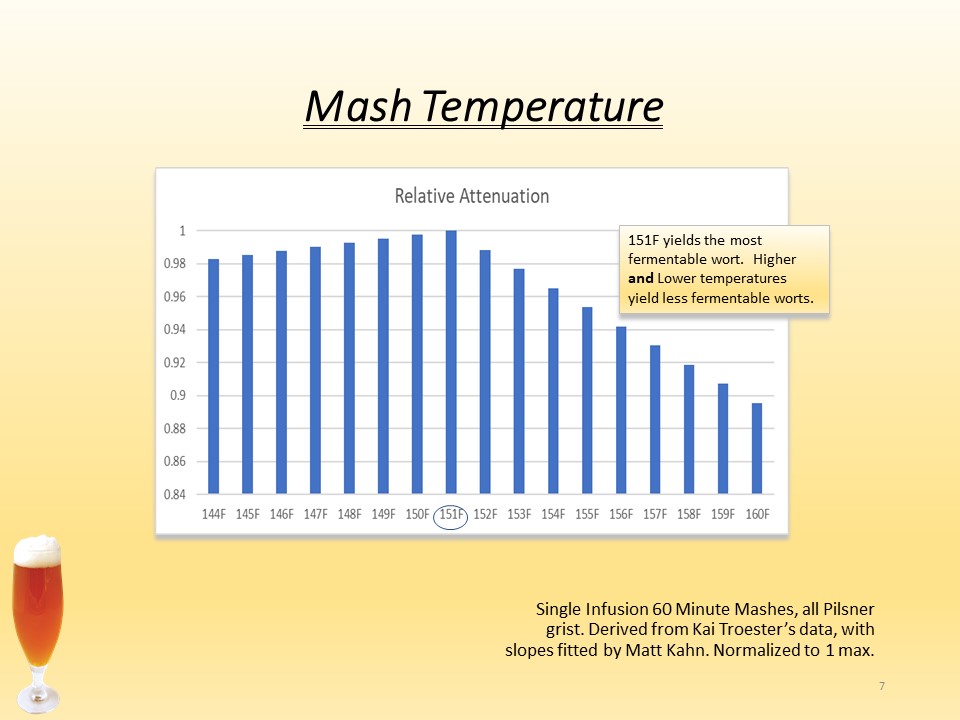

My FG reading after 1.5 weeks : 1.020 I am using a conical fermenter, I am worried that the yeast may be getting trapped in the trub after a very active fermentation, and gave it a swirl this morning. My friend also said my hydrometer may be off, so I will test calibration after work. My fermentation temps is ~70F. Mash temp was 68C.

Also I am getting a re-occuring off-flavor of chemicals/bleach, I use no-rinse sanstar..

This is my second all-grain batch in a row coming in short on my FG after fermentation has slowed. Here is the current recipe:

- 4.8 kg Pale malt

- 0.23 kg Abbey malt

- 0.23 kg Crystal 15 malt

- 1 oz Willamette for 60 min

- 0.6 oz Willamette for 20 min

- 0.6 oz Willamette for 1 min

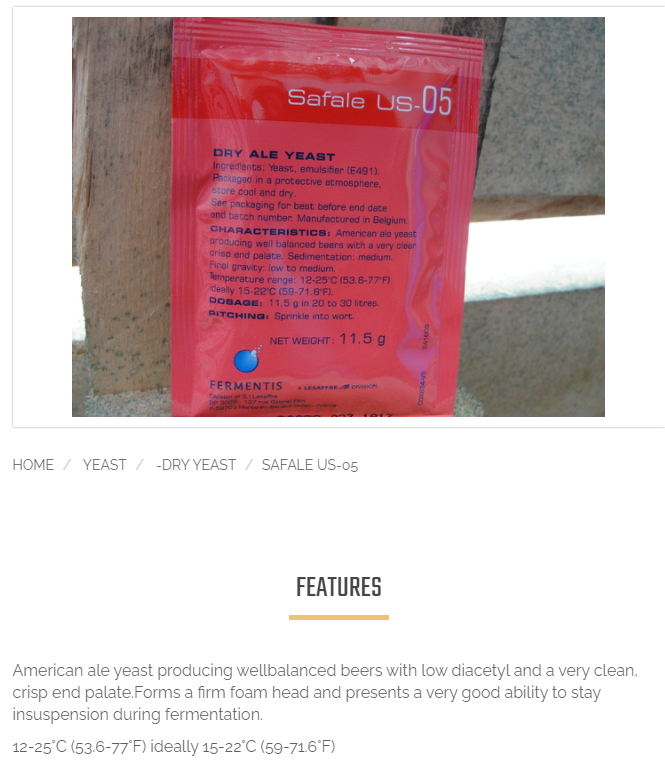

- Ferment Safale US-05

FG: 1.013

Target ABV: 5%

My FG reading after 1.5 weeks : 1.020 I am using a conical fermenter, I am worried that the yeast may be getting trapped in the trub after a very active fermentation, and gave it a swirl this morning. My friend also said my hydrometer may be off, so I will test calibration after work. My fermentation temps is ~70F. Mash temp was 68C.

Also I am getting a re-occuring off-flavor of chemicals/bleach, I use no-rinse sanstar..

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)