I purchased what looked like the strongest epoxy available at lowes. I carefully applied it to both sides of the cap after securing the two lines in place; it dried nice and solid on both ends. After waiting twice the recommended time just to be sure it was dry, I did a test run. While the seal is air and water tight, it is not able to hold any amount of pressure over about 5psi. This obviously is useless for my application.

So the general problem I have had in designing this thing is that I don't want to have to use any kind of brass tee as 1)the brass is not made to make any kind of seal with anything other than brass or copper tubing and 2)I don't like the idea of the fittings for the co2 valve and feed line costing more then the co2 pump, feed line/tap, and keg all put together. All the tutorials I have found and posted here so far have been able to jerry-rig it into a working state, but all required some specialized tools and soldering, neither of which I have. The easiest and most effective way I can think of to make this work is to do what I have been trying to do, which is have two seperate holes in the cap, one for the air valve, and one for the feed line. This is very difficult to do with a standard 38mm cap as you only actually have about 25mm or so to work with before you start affecting the gasket. You could possibly do it if you could find some 1/8 or 1/16 compression couplings, but I have not been able to and am not sure they even make them that small. If they do, and someone can find them and make that idea work, please post your results here.

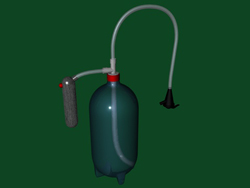

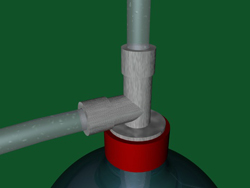

Since I am unable to make the compression pieces small enough to fit into a cap so small, I am now looking at just making the cap bigger. I actually thought about doing that somehow in the past; anything I could've done probably would not have been a very strong seal. Then I was wandering around my local HEB yesterday, and I stumbled upon a 5 gallon water bottle with handle, on sale for $5. I grabbed one, should've grabbed all five of them...then after getting home I find this thread:

https://www.homebrewtalk.com/f35/homemade-keg-5326/ After a quick chat with denny, I have deduced that the 5 gallon water bottle will hold the pressure, so long as it is properly regulated. He suggested a pressure relief valve, which I found for about $10. I then found a PSI regulator with built in gauge for $10. I've already ordered a CO2 bike pump, so am now waiting for both of these to arrive. Once they do, it's back to lowes to get the compression fittings to attach to the water bottle lid(one for the feed line, one for the regulator/co2 pump assembly). Clearly this is no longer a bike pump keg, and it's not even an original idea anymore, but damn it I've come this far, I might as well finish what I started.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)