After brewing many of these beers (and other hoppy IPAs) I think I've finally solved a lot of my prior issues slowly thanks to experience and advice from everyone here. Some of you may benefit from this simple advice if you are disappointed in some of your IPAs. I've used all of these techniques separately, but I finally put them all together and am very happy with the results. It's very simple, but for some reason it took me awhile to realize it, but better late than never. We've all probably thought about 1) cans of commercial NEIPA tasting great after several weeks and also 2) about inverting the cans (or kegs) before pouring to get more particulate into suspension (more flavor in the particulate) and about 3) low oxygen being a major key to great IPA flavor. I've tried a few brews now the following way, and I really like the results:

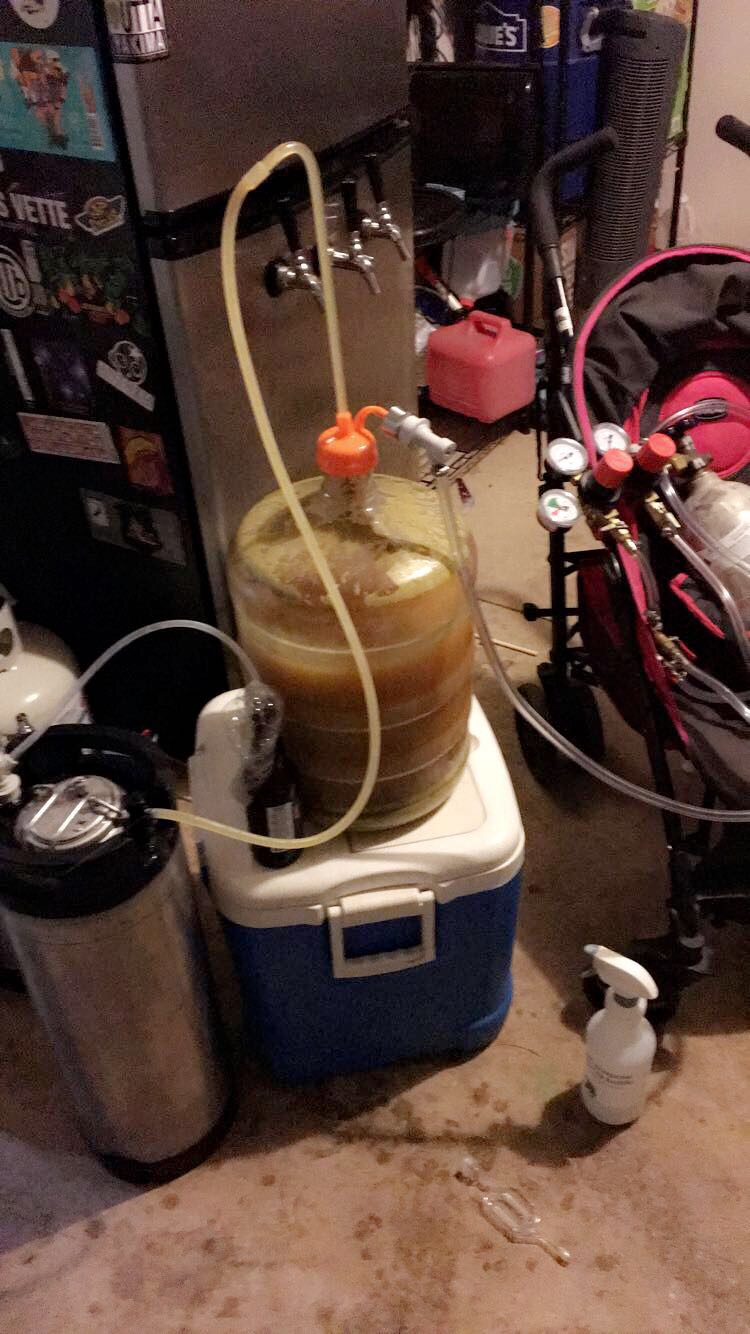

I ferment in my corny kegs with a CBDS (or sometimes in my 6.5G carboys again!), dry hop during fermentation or after dropping yeast some or whatever you like to do (still playing around with that myself!) Let the beer spund or force carb it in primary (or rack it before carbonating if using a glass/plastic carboy obviously) and then let it rest in your keezer for a few days to a week, sampling as you want. Then, once the really big particulate and hops pieces have dropped out (to prevent any clogging of poppets, etc.) transfer to a purged keg.

I have had issues using the closed system transfer with carbonated beer in kegs (bev to bev line and gas to gas line on the kegs with a gravity transfer), so my new SOP is to hook up my primary keg with the CBDS at like 20 psi using the CO2 cylinder and push it to the receiving keg with a spunding valve on the receiving keg gas post set at like 12-15 psi (thank you whoever mentioned this method in an earlier post - works great!) When the primary keg starts sputtering, disconnect it all and you are good to go. No loss of siphon and great, O2-free transfer. Yes, there may be a miniscule aroma loss from the spund valve, but I doubt it is much, and it prevents the dreaded stuck transfer that I have experienced.

I used to just serve off of primary using the CBDS but there are two issues that have slowly revealed themselves to me. One, you can start to get some yeasty flavors or weird hop flavors on some batches I think, especially with more time and more importantly, the delicious particulate/protein-hop suspensions can start to drop out of the beer leaving the beer to start tasting less hoppy as it starts to clear more and more. This is especially true with the CBDS, which serves from the top of the keg. I have actually had beers start out hazy, clarify up quite a bit and then after several pours, start to get cloudy and tastier again as the CBDS catches up to the dropping particulate in the lower portion of the keg! It still tastes good, but I really like all of that hazy hoppiness just like you just racked it the day before to stay in the beer and be more consistent.

Soooo, once you have the receiving keg full of your delicious beer (with a normal dip tube in the receiving keg) put it into your keezer and serve at will. Periodically, just lift the keg out of the keezer and tip it over the edge of the keezer and rock it a few times over the lip of the keezer and back to mix it all up. It sounds stupid, but you will be mixing in the hops (and some yeast of course but i don't mind at all as long as you have racked when the yeast has dropped out some from primary) and protein back into solution. After inverting the keg you will notice the beer is hazier and gets a hop boost if you haven't done it for awhile. I really think this is a great way to keep the beer tasting more like a can of IPA that you have mixed up and consumed. That's it, no genius insight, but putting it all together has resulted in great, long-lasting hazy, delicious beer for me. I was always wondering why a perfectly O2-free beer started tasting less hoppy to me. I think you have to rack and invert the keg to keep the hop levels at the absolute maximum.

Just a side note on CO2-purging: I've tried purging the receiving keg with fermentation gas from a keg to keg purge as well as a 6.5G glass carboy to keg purge. Both seem to work great. I'd recommend investing a little time to hook up whatever primary you have to a sanitized keg on brew day and just let it go until you need to disconnect it for dry hopping or whatever. It's awesome to be able to just go down and grab the sanitized, purged keg that is ready to receive the primary wort when it is time to rack. No fussing with filling it with star san or water and pushing it all out, etc. My only concern has been not blowing up my glass carboy (which I use if I need a full 5G to the serving keg or if I am out of clean kegs to use to ferment with) doing this if something gets clogged. So far it has worked well for me when I've tried it with carboys, but I suppose it could go wrong if there is a blowoff clog. I try to not fill my primary too full and I use anti-foam.

Anyway, that was long-winded, but give this a try if you feel like you're still not getting long-lasting hop flavor even though you've implemented one or more of the techniques that we've learned about from everyone on this thread. I am starting to think of my final serving keg as a very large can of IPA that needs to be rolled around before serving! yum!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)