This beer just got 3rd out of 105 entries in the Reuben’s Hop Idol comp. haven’t received a score sheet back yet. It’s good but a few tweaks definitely would have made it better. This has been in the keg for 5 weeks with 10 of those days being at 31*. Permanent haze stability and no loss in aroma or hop impact. Below is the recipe with all processes laid out if anyone cares. Including the subtle tweaks to make it better.

6 gallons into the FV

1.062

10# Rahr 2 Row

4# Admiral Maltings Gallagher Pale

12oz Weyermann Carafoam

5oz Honey Malt

4oz Acidulated

Imperial Tartan yeast

Mash pH 5.34

Sparge pH 5.3

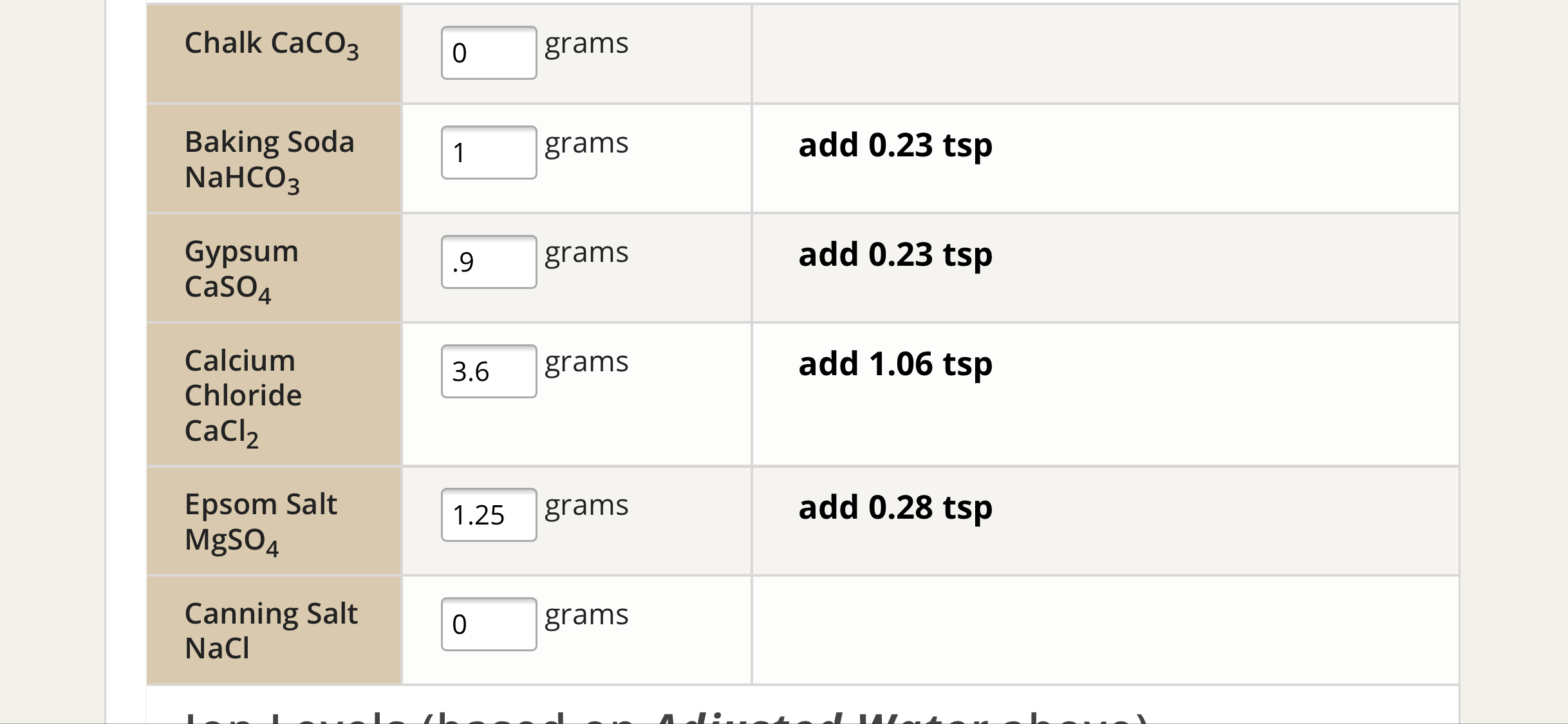

Water Profile:

Ca: 85

Mg: 6

Na: 30

So4: 155

Cl: 86.7

RO water. Salts added to Mash and sparge except sparge gypsum which was added to kettle.

75 min @149 (this was a mistake)

30 min @ 162

Kettle Full pH 5.4

2ml lactic @ 60

3ml lactic @ FO

90 minute Boil

4ml hop shot @ 60

1oz Calypso @ 10

2oz Southern Passion @ FO (200f)

2oz Galaxy @ FO (200f)

1oz Nugget @ 170

WP 20

PH into FV 5.06

BTB in Mash

1/2 tab whirlfloc in kettle

1 servomyces capsule

Added the hops at FO but instantly cooled to 170 with immersion chiller. Added Nugget at 170. WP for 20.

Targeted an est .75mil/ml/*plato

2 min O2 at .5ml/sec

Pitched 2/5 @ 62, fermented 66, raised to 70 on day 4 or 5.

I attach the pressure transfer fitting that’s hooked up to Co2 on a manifold for the last 1-2 Plato of fermentation. It helps to maintain positive pressure when soft cooling.

Cooled to 60 on day 6 after forced diacetyl test.

Left for 24 hours at 60.

Pulled as much yeast as possible. Tartan floccs really well so it was a ton of yeast and the beer was very clear.

Dry Hop:

5oz Southern Passion

2oz Galaxy

2oz Sabro

Just pull the pressure transfer piece and pour em in with a funnel. Attach the pressure transfer piece again and purge the head space a few times. Leave with 2.5 psi head pressure.

3 days at 60*

Cool to 45 for 36 hours.

Transfer to an O2 purged keg. Carbed at 31* for 10 days.

Issue with the beer was the mash temp. I’ve struggled to get tartan to attenuate in the past. I was targeting 1.014 and got 1.0095. The resulting beer was a little too dry and the water profiles/bitterness were out of balance. Also only half the dry hops even made it into the beer. I have the SS brewtech conicals and so often a pile of the hops get lodged into the cooling coil and never make it into the beer. Hop flavor suffered a bit. So a little more hop flavor and a little more body and this would be pretty spot on. The Southern Passion hops also aren’t that potent. I wouldn’t make it again with them but they weren’t horrible. Sabro and Galaxy are so strong they over power everything anyways.

View attachment 618680

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)