a very extravagent purging setup

It's not too bad.

This thread is awesome:

Pressurized Closed Loop Corny Keg Fermenting

A lot of guys go much further to eliminate O2 exposure:

Interesting German Brewing PDF

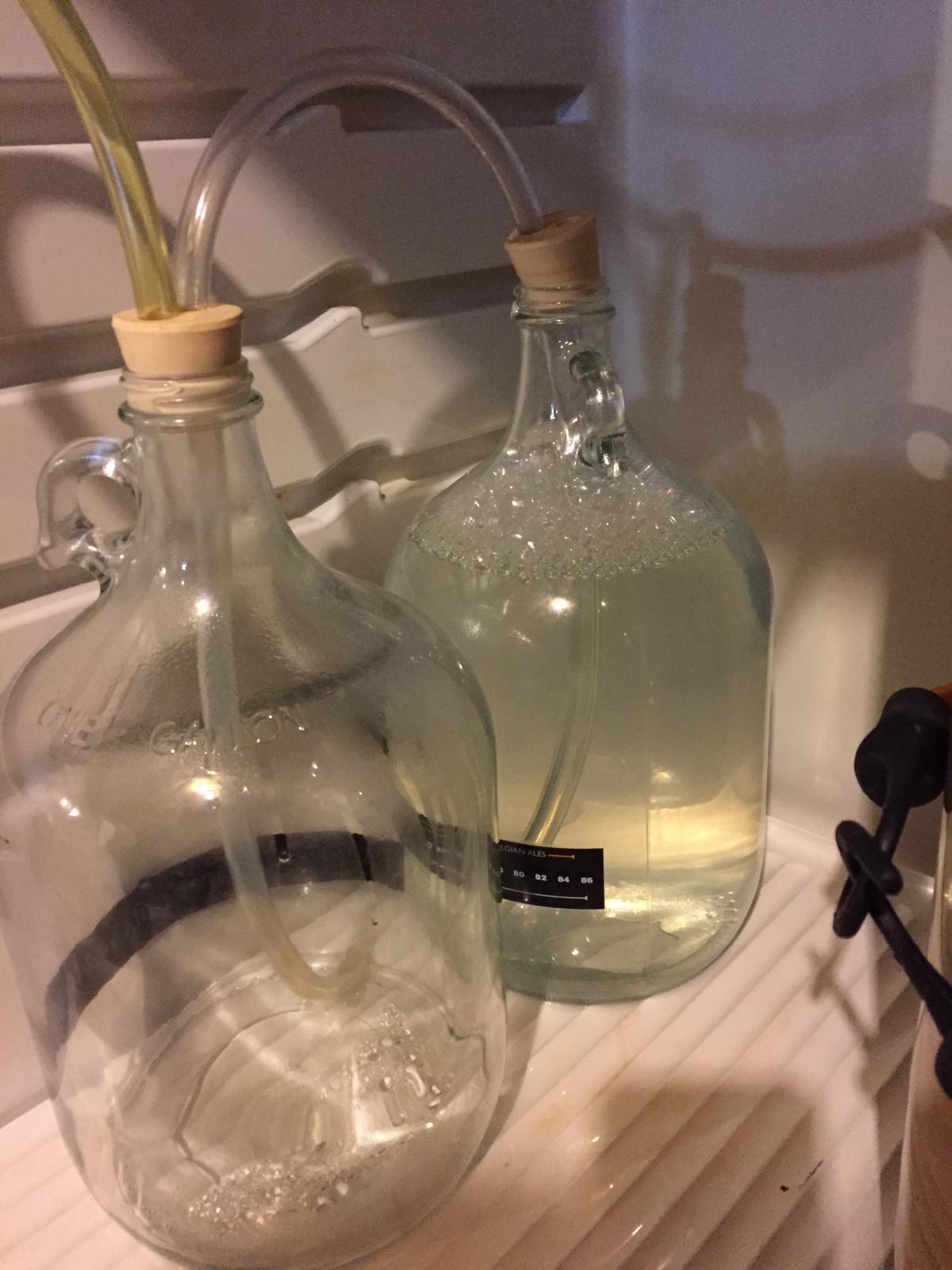

a very extravagent purging setup

This thread is awesome:

Pressurized Closed Loop Corny Keg Fermenting

What's everyone's thoughts on cold crashing this style beer? I've done a couple batches and do all my dry hopping in the primary. I've always done a closed transfer with co2 from carboy to keg and just let it crash in the keg. I wouldn't mind dropping out more hop matter in the carboy before transferring to the keg. Is cold crashing in the primary setting me up for unnecessary oxygen exposure?

I do it all of the time and I doubt it has much impact on the beer longevity. I've tried hooking up a CO2 line with very low pressure on it for the chill, and I've just done it with no CO2 line. I pull out the stopper right before I rack to keg, some air sucks into the headspace rapidly, I rack to keg, and I drink delicious beer for a couple months.

I just crashed one of my beers this weekend, and I noticed that literally within a few hours of starting to cool it, the hops had dropped down to the bottom!

I've never cold crashed with co2. When you cold crash without co2, are you using a solid stopper? My usual process is removing the blow off tube and replacing it with a vodka filled s-type airlock and then cold crashing.

What's everyone's thoughts on cold crashing this style beer? I've done a couple batches and do all my dry hopping in the primary. I've always done a closed transfer with co2 from carboy to keg and just let it crash in the keg. I wouldn't mind dropping out more hop matter in the carboy before transferring to the keg. Is cold crashing in the primary setting me up for unnecessary oxygen exposure?

Personally ( and I don't have any other brews of this kind under my belt other then my current one) I don't see how it would hurt at all, if fact it may even help, as there are TONS of hop matter in the fermenters.

There is NO doubt that it helps to settle hop matter and maybe some yeast. It makes racking a lot easier. The risk is oxygen exposure (not sure it is significant or not.)

My thoughts are that the oxygen may react with some of the surface beer, but I just don't think it is that big of a deal. I'd have to do a side-by-side to say for sure. I've just been too lazy to use my pressure-transfer setup, and it kind of worries me pressurizing my carboy (maybe irrationally.)

I am much more afraid of oxygen than bacteria/yeast at that point, so I just put a solid stopper into the carboy when I start the cold crash. I leave it that way until I am ready to keg. Right before I rack to the keg, I pull out the stopper (it has a pretty big negative pressure in the carboy, so it is hard to pull out sometimes), a rush of air swooshes into the carboy, and then I put in my racking cane and rack.

My thoughts are that the oxygen may react with some of the surface beer, but I just don't think it is that big of a deal. I'd have to do a side-by-side to say for sure. I've just been too lazy to use my pressure-transfer setup, and it kind of worries me pressurizing my carboy (maybe irrationally.)

I've been meaning to share a technique I've been using recently to cold crash with virtually no oxygen exposure. It doesn't require hooking up CO2, a second regulator, or any extra equipment other than $2 worth of drilled stoppers.

I think cold crashing this beer is important. Before I started cold crashing, I would get at least a week or two of harsh bite from suspended hop particles. Sometimes it never really went away. I would also have a bunch of sludge at the bottom of the keg when it kicked, which would mess up my beer lines, etc.

I also think avoiding oxygen exposure is very important to this style, and I'm just not OK with sucking a bunch of air into the headspace while cold crashing. Before I started doing this, I could actually see a thin dark layer of oxidized beer forming at the top of the fermentor while crashing.

So, here's what I came up with for storing some CO2 from fermentation, and feeding it back into the primary while cold crashing. I had seen some other threads on this talking about mylar balloons and all kinds of stuff, but I think this is a more elegant, sanitary approach.

Here's how it works: I start off with the blowoff tube (the yellowed one) in a normal jar or whatever. Once I am past any potential blowoff risk, but still actively fermenting, I put that hose into the top of the first jug, which starts off filled to the top with star san. The CO2 pressure pushes that star san through the jumper line into the second jug, which fills up and then just allows excess CO2 to bubble out into the atmosphere. The first jug is now full of CO2. This is what's pictured below.

When I start to cold crash, the headspace contracts, which sucks star san from the second jug back into the first, and CO2 from the first jug back into the fermentor. That fermentor is a thin-walled plastic Fermonster, and there's little enough negative pressure that it doesn't even buckle. At the end of the cold crash, the first jug is filled back up about 1/2 to 2/3 of the way.

When I'm done cold crashing, I just take the stopper out of the fermentor and hang a CO2 line in there, trickling CO2 to maintain positive pressure as the beer siphons out. There's no rush of air when I take the stopper out because there's no negative pressure. I siphon into a keg that has been filled with star san and purged with CO2, so the beer comes into no contact with oxygen.

I do all of my dry hopping loose in primary, but by cold crashing I get almost no trub or hop matter into the keg. When the keg kicks, the bottom is nearly clean.

The one thing that may be tricky is finding a double-drilled stopper. The guy at my LHBS has a drill bit in the back that does it, so he just gave me those two stoppers for $1 each. I think I've seen threads about people doing it themselves with a piece of copper pipe or something. I guess a normal drill bit doesn't work too well. The jugs are 1-gallon fermentors I had lying around.

Anyway, hope someone finds this helpful. This is the best balance I've found between (relative) simplicity and feeling like I'm doing the best I can do avoid O2 and improve my beer.

Are you using a glass carboy? I used to use a solid stopper during cold crashing but read somewhere not to so I stopped. Can't remember the exact reason it wasn't recommended. Something about the carboy breaking.

I've been meaning to share a technique I've been using recently to cold crash with virtually no oxygen exposure. It doesn't require hooking up CO2, a second regulator, or any extra equipment other than $2 worth of drilled stoppers.

I think cold crashing this beer is important. Before I started cold crashing, I would get at least a week or two of harsh bite from suspended hop particles. Sometimes it never really went away. I would also have a bunch of sludge at the bottom of the keg when it kicked, which would mess up my beer lines, etc.

I also think avoiding oxygen exposure is very important to this style, and I'm just not OK with sucking a bunch of air into the headspace while cold crashing. Before I started doing this, I could actually see a thin dark layer of oxidized beer forming at the top of the fermentor while crashing.

So, here's what I came up with for storing some CO2 from fermentation, and feeding it back into the primary while cold crashing. I had seen some other threads on this talking about mylar balloons and all kinds of stuff, but I think this is a more elegant, sanitary approach.

Here's how it works: I start off with the blowoff tube (the yellowed one) in a normal jar or whatever. Once I am past any potential blowoff risk, but still actively fermenting, I put that hose into the top of the first jug, which starts off filled to the top with star san. The CO2 pressure pushes that star san through the jumper line into the second jug, which fills up and then just allows excess CO2 to bubble out into the atmosphere. The first jug is now full of CO2. This is what's pictured below.

When I start to cold crash, the headspace contracts, which sucks star san from the second jug back into the first, and CO2 from the first jug back into the fermentor. That fermentor is a thin-walled plastic Fermonster, and there's little enough negative pressure that it doesn't even buckle. At the end of the cold crash, the first jug is filled back up about 1/2 to 2/3 of the way.

When I'm done cold crashing, I just take the stopper out of the fermentor and hang a CO2 line in there, trickling CO2 to maintain positive pressure as the beer siphons out. There's no rush of air when I take the stopper out because there's no negative pressure. I siphon into a keg that has been filled with star san and purged with CO2, so the beer comes into no contact with oxygen.

I do all of my dry hopping loose in primary, but by cold crashing I get almost no trub or hop matter into the keg. When the keg kicks, the bottom is nearly clean.

The one thing that may be tricky is finding a double-drilled stopper. The guy at my LHBS has a drill bit in the back that does it, so he just gave me those two stoppers for $1 each. I think I've seen threads about people doing it themselves with a piece of copper pipe or something. I guess a normal drill bit doesn't work too well. The jugs are 1-gallon fermentors I had lying around.

Anyway, hope someone finds this helpful. This is the best balance I've found between (relative) simplicity and feeling like I'm doing the best I can do avoid O2 and improve my beer.

I've been meaning to share a technique I've been using recently to cold crash with virtually no oxygen exposure. It doesn't require hooking up CO2, a second regulator, or any extra equipment other than $2 worth of drilled stoppers.

I think cold crashing this beer is important. Before I started cold crashing, I would get at least a week or two of harsh bite from suspended hop particles. Sometimes it never really went away. I would also have a bunch of sludge at the bottom of the keg when it kicked, which would mess up my beer lines, etc.

I also think avoiding oxygen exposure is very important to this style, and I'm just not OK with sucking a bunch of air into the headspace while cold crashing. Before I started doing this, I could actually see a thin dark layer of oxidized beer forming at the top of the fermentor while crashing.

So, here's what I came up with for storing some CO2 from fermentation, and feeding it back into the primary while cold crashing. I had seen some other threads on this talking about mylar balloons and all kinds of stuff, but I think this is a more elegant, sanitary approach.

Here's how it works: I start off with the blowoff tube (the yellowed one) in a normal jar or whatever. Once I am past any potential blowoff risk, but still actively fermenting, I put that hose into the top of the first jug, which starts off filled to the top with star san. The CO2 pressure pushes that star san through the jumper line into the second jug, which fills up and then just allows excess CO2 to bubble out into the atmosphere. The first jug is now full of CO2. This is what's pictured below.

When I start to cold crash, the headspace contracts, which sucks star san from the second jug back into the first, and CO2 from the first jug back into the fermentor. That fermentor is a thin-walled plastic Fermonster, and there's little enough negative pressure that it doesn't even buckle. At the end of the cold crash, the first jug is filled back up about 1/2 to 2/3 of the way.

When I'm done cold crashing, I just take the stopper out of the fermentor and hang a CO2 line in there, trickling CO2 to maintain positive pressure as the beer siphons out. There's no rush of air when I take the stopper out because there's no negative pressure. I siphon into a keg that has been filled with star san and purged with CO2, so the beer comes into no contact with oxygen.

I do all of my dry hopping loose in primary, but by cold crashing I get almost no trub or hop matter into the keg. When the keg kicks, the bottom is nearly clean.

The one thing that may be tricky is finding a double-drilled stopper. The guy at my LHBS has a drill bit in the back that does it, so he just gave me those two stoppers for $1 each. I think I've seen threads about people doing it themselves with a piece of copper pipe or something. I guess a normal drill bit doesn't work too well. The jugs are 1-gallon fermentors I had lying around.

Anyway, hope someone finds this helpful. This is the best balance I've found between (relative) simplicity and feeling like I'm doing the best I can do avoid O2 and improve my beer.

I've been meaning to share a technique I've been using recently to cold crash with virtually no oxygen exposure. It doesn't require hooking up CO2, a second regulator, or any extra equipment other than $2 worth of drilled stoppers.

I think cold crashing this beer is important. Before I started cold crashing, I would get at least a week or two of harsh bite from suspended hop particles. Sometimes it never really went away. I would also have a bunch of sludge at the bottom of the keg when it kicked, which would mess up my beer lines, etc.

I also think avoiding oxygen exposure is very important to this style, and I'm just not OK with sucking a bunch of air into the headspace while cold crashing. Before I started doing this, I could actually see a thin dark layer of oxidized beer forming at the top of the fermentor while crashing.

So, here's what I came up with for storing some CO2 from fermentation, and feeding it back into the primary while cold crashing. I had seen some other threads on this talking about mylar balloons and all kinds of stuff, but I think this is a more elegant, sanitary approach.

Here's how it works: I start off with the blowoff tube (the yellowed one) in a normal jar or whatever. Once I am past any potential blowoff risk, but still actively fermenting, I put that hose into the top of the first jug, which starts off filled to the top with star san. The CO2 pressure pushes that star san through the jumper line into the second jug, which fills up and then just allows excess CO2 to bubble out into the atmosphere. The first jug is now full of CO2. This is what's pictured below.

When I start to cold crash, the headspace contracts, which sucks star san from the second jug back into the first, and CO2 from the first jug back into the fermentor. That fermentor is a thin-walled plastic Fermonster, and there's little enough negative pressure that it doesn't even buckle. At the end of the cold crash, the first jug is filled back up about 1/2 to 2/3 of the way.

When I'm done cold crashing, I just take the stopper out of the fermentor and hang a CO2 line in there, trickling CO2 to maintain positive pressure as the beer siphons out. There's no rush of air when I take the stopper out because there's no negative pressure. I siphon into a keg that has been filled with star san and purged with CO2, so the beer comes into no contact with oxygen.

I do all of my dry hopping loose in primary, but by cold crashing I get almost no trub or hop matter into the keg. When the keg kicks, the bottom is nearly clean.

The one thing that may be tricky is finding a double-drilled stopper. The guy at my LHBS has a drill bit in the back that does it, so he just gave me those two stoppers for $1 each. I think I've seen threads about people doing it themselves with a piece of copper pipe or something. I guess a normal drill bit doesn't work too well. The jugs are 1-gallon fermentors I had lying around.

Anyway, hope someone finds this helpful. This is the best balance I've found between (relative) simplicity and feeling like I'm doing the best I can do avoid O2 and improve my beer.

I've been meaning to share a technique I've been using recently to cold crash with virtually no oxygen exposure. It doesn't require hooking up CO2, a second regulator, or any extra equipment other than $2 worth of drilled stoppers.

I think cold crashing this beer is important. Before I started cold crashing, I would get at least a week or two of harsh bite from suspended hop particles. Sometimes it never really went away. I would also have a bunch of sludge at the bottom of the keg when it kicked, which would mess up my beer lines, etc.

I also think avoiding oxygen exposure is very important to this style, and I'm just not OK with sucking a bunch of air into the headspace while cold crashing. Before I started doing this, I could actually see a thin dark layer of oxidized beer forming at the top of the fermentor while crashing.

So, here's what I came up with for storing some CO2 from fermentation, and feeding it back into the primary while cold crashing. I had seen some other threads on this talking about mylar balloons and all kinds of stuff, but I think this is a more elegant, sanitary approach.

Here's how it works: I start off with the blowoff tube (the yellowed one) in a normal jar or whatever. Once I am past any potential blowoff risk, but still actively fermenting, I put that hose into the top of the first jug, which starts off filled to the top with star san. The CO2 pressure pushes that star san through the jumper line into the second jug, which fills up and then just allows excess CO2 to bubble out into the atmosphere. The first jug is now full of CO2. This is what's pictured below.

When I start to cold crash, the headspace contracts, which sucks star san from the second jug back into the first, and CO2 from the first jug back into the fermentor. That fermentor is a thin-walled plastic Fermonster, and there's little enough negative pressure that it doesn't even buckle. At the end of the cold crash, the first jug is filled back up about 1/2 to 2/3 of the way.

When I'm done cold crashing, I just take the stopper out of the fermentor and hang a CO2 line in there, trickling CO2 to maintain positive pressure as the beer siphons out. There's no rush of air when I take the stopper out because there's no negative pressure. I siphon into a keg that has been filled with star san and purged with CO2, so the beer comes into no contact with oxygen.

I do all of my dry hopping loose in primary, but by cold crashing I get almost no trub or hop matter into the keg. When the keg kicks, the bottom is nearly clean.

The one thing that may be tricky is finding a double-drilled stopper. The guy at my LHBS has a drill bit in the back that does it, so he just gave me those two stoppers for $1 each. I think I've seen threads about people doing it themselves with a piece of copper pipe or something. I guess a normal drill bit doesn't work too well. The jugs are 1-gallon fermentors I had lying around.

Anyway, hope someone finds this helpful. This is the best balance I've found between (relative) simplicity and feeling like I'm doing the best I can do avoid O2 and improve my beer.

This is really clever!, if you can't find a double drilled stopper you can use a Krausen Catcher from NorCal using a big mason jar.

I'm really enjoying this style of ale. I found this recipe searching youtube and I was really happy the way my beer turned out

https://www.youtube.com/watch?v=5NPck6LOD1A&t=3s

Only a 30 minute boil. Interesting

I've been meaning to share a technique I've been using recently to cold crash with virtually no oxygen exposure. It doesn't require hooking up CO2, a second regulator, or any extra equipment other than $2 worth of drilled stoppers.

I think cold crashing this beer is important. Before I started cold crashing, I would get at least a week or two of harsh bite from suspended hop particles. Sometimes it never really went away. I would also have a bunch of sludge at the bottom of the keg when it kicked, which would mess up my beer lines, etc.

I also think avoiding oxygen exposure is very important to this style, and I'm just not OK with sucking a bunch of air into the headspace while cold crashing. Before I started doing this, I could actually see a thin dark layer of oxidized beer forming at the top of the fermentor while crashing.

So, here's what I came up with for storing some CO2 from fermentation, and feeding it back into the primary while cold crashing. I had seen some other threads on this talking about mylar balloons and all kinds of stuff, but I think this is a more elegant, sanitary approach.

Here's how it works: I start off with the blowoff tube (the yellowed one) in a normal jar or whatever. Once I am past any potential blowoff risk, but still actively fermenting, I put that hose into the top of the first jug, which starts off filled to the top with star san. The CO2 pressure pushes that star san through the jumper line into the second jug, which fills up and then just allows excess CO2 to bubble out into the atmosphere. The first jug is now full of CO2. This is what's pictured below.

When I start to cold crash, the headspace contracts, which sucks star san from the second jug back into the first, and CO2 from the first jug back into the fermentor. That fermentor is a thin-walled plastic Fermonster, and there's little enough negative pressure that it doesn't even buckle. At the end of the cold crash, the first jug is filled back up about 1/2 to 2/3 of the way.

When I'm done cold crashing, I just take the stopper out of the fermentor and hang a CO2 line in there, trickling CO2 to maintain positive pressure as the beer siphons out. There's no rush of air when I take the stopper out because there's no negative pressure. I siphon into a keg that has been filled with star san and purged with CO2, so the beer comes into no contact with oxygen.

I do all of my dry hopping loose in primary, but by cold crashing I get almost no trub or hop matter into the keg. When the keg kicks, the bottom is nearly clean.

The one thing that may be tricky is finding a double-drilled stopper. The guy at my LHBS has a drill bit in the back that does it, so he just gave me those two stoppers for $1 each. I think I've seen threads about people doing it themselves with a piece of copper pipe or something. I guess a normal drill bit doesn't work too well. The jugs are 1-gallon fermentors I had lying around.

Anyway, hope someone finds this helpful. This is the best balance I've found between (relative) simplicity and feeling like I'm doing the best I can do avoid O2 and improve my beer.

I'm very interested in a setup similar to this for cold crashing but I have a question. Correct me if I'm wrong but say I'm doing a two stage dry hop in the primary. I could put the first stage in towards the end of active fermentation, the same time it's suggested that the blow off tube be hooked up to the two chambers. At that time co2 from the still active fermentation will fill the first bottle and push the sanitizer solution into the second. When I'd go to add the second dry hop to the fermenter after active fermentation slows down, won't I lose all the co2 that's now in the first bottle thus negating the entire process?

I've done 30 min boils with this style. Works great, since this style doesn't need a 60 min hops boil (the longest hops boil I use for NEIPA is 15 min).

I was worried that I mashed too low due to some issues I had with my controller, but this came out great! Next time think I'm going to use just a little crystal.