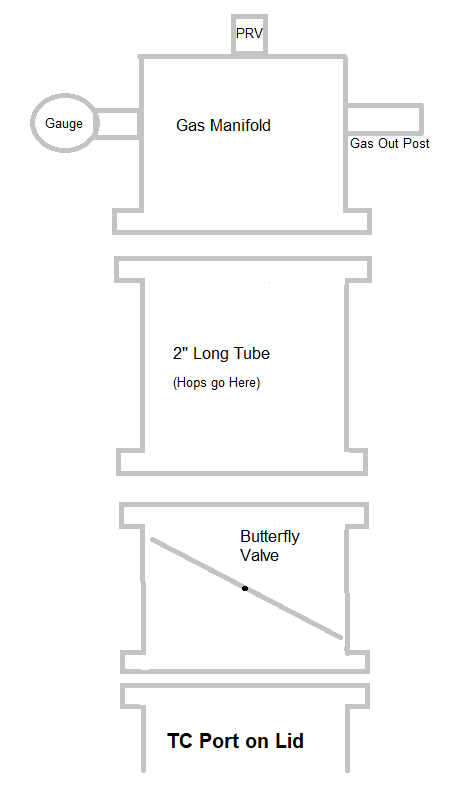

OK, another badly-drawn sketch from Max Stout.

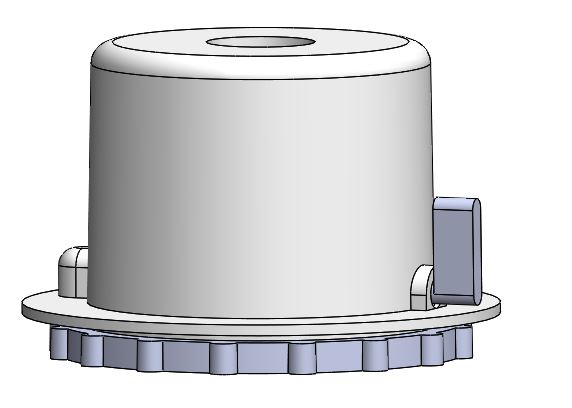

Make a hops container that mounts atop a fermenter. The hops container has a butterfly valve on the bottom to release the hops and a blowoff connector on its top. The butterfly valve would be modified such that it cannot close all the way. At the closed position there's just enough aperture to let out escaping CO2 during fermentation, but not enough for any of the pellets to fall through. When the valve is opened all the way, the pellets drop. During fermentation, the valve is in the "closed" position and CO2 passes through the hops vessel, through the blowout and eventually displacing most of the air. The hops stay in a mostly O2-free environment. The Dry Hop Hopper.

Make a hops container that mounts atop a fermenter. The hops container has a butterfly valve on the bottom to release the hops and a blowoff connector on its top. The butterfly valve would be modified such that it cannot close all the way. At the closed position there's just enough aperture to let out escaping CO2 during fermentation, but not enough for any of the pellets to fall through. When the valve is opened all the way, the pellets drop. During fermentation, the valve is in the "closed" position and CO2 passes through the hops vessel, through the blowout and eventually displacing most of the air. The hops stay in a mostly O2-free environment. The Dry Hop Hopper.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)