Greetings,

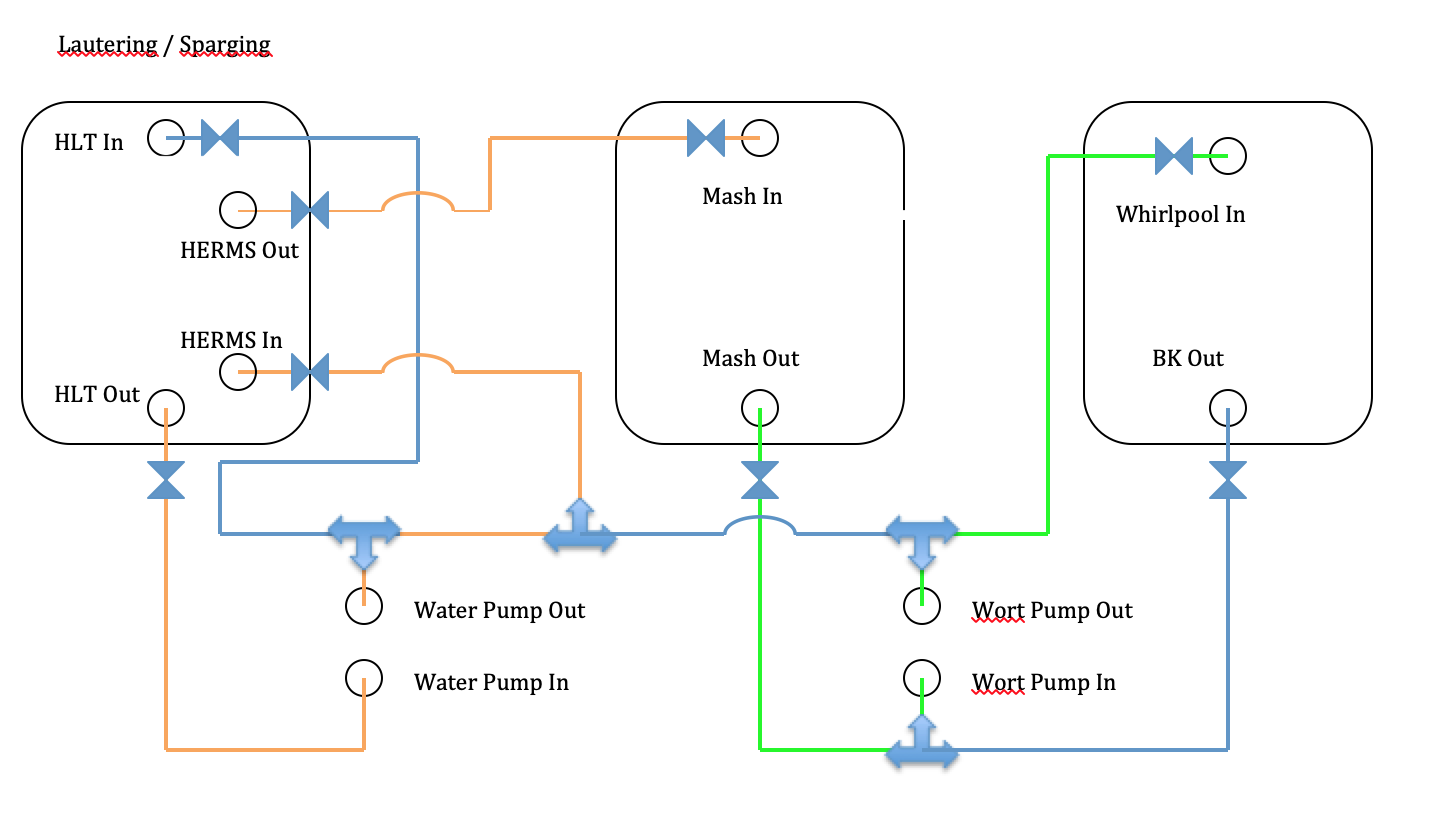

Looking to go to a no hose change set up, just for the sake of it and to help out when I am brewing with other people. This may also be a trial run for a full hard plumbed system later down the track.

Could anyone with experience chime in to see if what I am proposing would work? All the valves on the pots are currently in place. I would need to purchase 4 3-way L valves, plus a couple more bits to connect it all up.

Currently cooling with a lid mounted immersion chiller.

Cheers.

Looking to go to a no hose change set up, just for the sake of it and to help out when I am brewing with other people. This may also be a trial run for a full hard plumbed system later down the track.

Could anyone with experience chime in to see if what I am proposing would work? All the valves on the pots are currently in place. I would need to purchase 4 3-way L valves, plus a couple more bits to connect it all up.

Currently cooling with a lid mounted immersion chiller.

Cheers.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)