When you transfer to these, do you just leave the ambient air in the headspace while cooling before pitching?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

No-Chill Brewing?

- Thread starter H-ost19

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

bjhbrew

Well-Known Member

- Joined

- Oct 15, 2016

- Messages

- 159

- Reaction score

- 90

The first time I used a corny for no chill I found that the rubber got very soft and it felt like the glue was giving away on the rubber base. Now I just put the corny into a small Rubbermaid bin with cold water in it before filling with hot wort. The water is just high enough to cover the rubber base and keeps the bottom cool enough that the rubber doesn’t become pliable, seems to work pretty good. I then go ahead and purge the head space a couple times with co2 and pressurize to about 15-20psi before leaving it to chill overnight. When I go to pitch the yeast the next day there is very little pressure remaining. I open it up, add the yeast and a floating dip tube, seal it back up and shake it for a minute. I’ve only just done around 6 brews using this method but so far I’ve been very happy with the results from no chill brewing.When using a corny keg, does the heat bother the rubber handles?

Would you pressurize the keg with co2 to prevent vacuum, or will this have negative effect on oxygen levels in wort?

Aside from cleaning, chilling is my least favorite part. Too many hoses and potential for problems

grzrk

Gary

- Joined

- May 30, 2020

- Messages

- 25

- Reaction score

- 17

Great info there about insulating the base. My one keg where the base is clearly deteriorating would probably turn to mush lol.The first time I used a corny for no chill I found that the rubber got very soft and it felt like the glue was giving away on the rubber base. Now I just put the corny into a small Rubbermaid bin with cold water in it before filling with hot wort. The water is just high enough to cover the rubber base and keeps the bottom cool enough that the rubber doesn’t become pliable, seems to work pretty good. I then go ahead and purge the head space a couple times with co2 and pressurize to about 15-20psi before leaving it to chill overnight. When I go to pitch the yeast the next day there is very little pressure remaining. I open it up, add the yeast and a floating dip tube, seal it back up and shake it for a minute. I’ve only just done around 6 brews using this method but so far I’ve been very happy with the results from no chill brewing.

It is interesting that the headspace CO2 that is absorbed into the wort doesn't seem to be enough to affect the later fermentation. I suppose the concentration is probably minimal enough to not be a factor, as long as there is enough oxygen in there from agitation. Thanks for the info! A keg just happened to become available around 11:30 last night, so a brew day is on the horizon....

- Joined

- May 15, 2015

- Messages

- 703

- Reaction score

- 455

No chill rocks. I just finish the boil, put the lid on the kettle, point a fan at the kettle, and go inside. The next day around lunchtime I transfer to fermentors and pitch yeast.

With 2 young kids and such little spare time, no chill helps open up opportunities to brew that would not exist otherwise; this is what got me doing it in the first place, after using the IC method for several years. Using the no chill approach I can start a brew session after the kids are in bed, no problem, even on a weeknight. If I tried that using the "full" chill process, I'd have to be out in the garage until 2am; with no-chill, it can be lights out by like 10pm. Luckily I work from home most of the time, so at lunch time the day after, I can do the transfer and pitch the yeast. After work that evening I can finish clean up. It takes a bit of planning but breaking up the process sure helps fit a time-consuming hobby into a busy life.

I've only used my immersion chiller once or twice in the last few years. I mean, there is definitely something to be said for just getting a brew done in a single session, but after 15-20 batches of no chill I simply do not see a downside to it.

EDIT TO ADD: for the sake of completeness I should mention that I did screw up one batch with a sloppy no-chill approach. It was in the absolute dead of summer and the wort did not chill as much as I hoped by lunch time the next day. I stupidly went ahead and pitched the yeast anyway because it was the only opportunity I had to do it that day, and the beer had an unwanted phenolic character to it. It was still drinkable but not at all what I was after. But this is my own stupidity in rushing, not a problem with the process itself.

With 2 young kids and such little spare time, no chill helps open up opportunities to brew that would not exist otherwise; this is what got me doing it in the first place, after using the IC method for several years. Using the no chill approach I can start a brew session after the kids are in bed, no problem, even on a weeknight. If I tried that using the "full" chill process, I'd have to be out in the garage until 2am; with no-chill, it can be lights out by like 10pm. Luckily I work from home most of the time, so at lunch time the day after, I can do the transfer and pitch the yeast. After work that evening I can finish clean up. It takes a bit of planning but breaking up the process sure helps fit a time-consuming hobby into a busy life.

I've only used my immersion chiller once or twice in the last few years. I mean, there is definitely something to be said for just getting a brew done in a single session, but after 15-20 batches of no chill I simply do not see a downside to it.

EDIT TO ADD: for the sake of completeness I should mention that I did screw up one batch with a sloppy no-chill approach. It was in the absolute dead of summer and the wort did not chill as much as I hoped by lunch time the next day. I stupidly went ahead and pitched the yeast anyway because it was the only opportunity I had to do it that day, and the beer had an unwanted phenolic character to it. It was still drinkable but not at all what I was after. But this is my own stupidity in rushing, not a problem with the process itself.

Last edited:

Using the no chill approach I can start a brew session after the kids are in bed, no problem, even on a weeknight. If I tried that using the "full" chill process, I'd have to be out in the garage until 2am; with no-chill, it can be lights out by like 10pm.

I don't quite understand that part. It doesn't need to take 4 hours to chill. I can chill to 65-70 degrees in 20-25 min with my IC, a couple blocks of ice that I threw in the freezer beforehand and a cheap pump. I did it yesterday in the middle of a Wisconsin winter as long as I keep the hose in my attached garage that stays above freezing. I have no doubt though that no chill works fine.

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid MFL)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

Zambezi Special

Well-Known Member

I can see that working very well with stainless steel. Would it also work for a speidel fermenter (those white/orange ones)?Almost 200 batches, all No-Chill. I wait 45 minutes for the temperature to drop below 70'C, pour it into the fermenter, seal it and put in the yeast and airlock tomorrow.

I always had oxidation issues when doing no chill. Unless the batch was very hoppy. I guess the hops oxidised first and therefore were sacrificed to keep the malt compounds unoxidized. It was always this dreaded almond flavour.... If I would do no chill today again, I would use something like ascorbic acid and try to minimise surface area etc. Basically kind of lodo, so that there's as little oxygen as possible present in the liquid during the chilling period. Elevated temperatures for prolonged time and oxygen is a very bad combination.

I ruined a speidel with no chill after one or two years of excessive usage with boiling wort. The lid does not close tightly anymore. But I think 70c should be fine. If I remember correctly, they are listed as stable up until 80c or something like that? Don't remember... But you can look it up in the internet on their pageI can see that working very well with stainless steel. Would it also work for a speidel fermenter (those white/orange ones)?

rancocas

Active Member

So I use half a Campden tab in my strike water, and do no splashing when emptying my boil kettle into my nochill drum. It must work, because I have never had that almond flavor.I always had oxidation issues when doing no chill. Unless the batch was very hoppy. I guess the hops oxidised first and therefore were sacrificed to keep the malt compounds unoxidized. It was always this dreaded almond flavour.... If I would do no chill today again, I would use something like ascorbic acid and try to minimise surface area etc. Basically kind of lodo, so that there's as little oxygen as possible present in the liquid during the chilling period. Elevated temperatures for prolonged time and oxygen is a very bad combination.

Boozey Boy

Member

Could you just put the fermenter straight in the cooler and let it chill that way? Edit ( I have a SS fermenter that i put in a chest freezer)I'm in the states, in the desert. I've been doing no-chill for at least the last two years. My version is just to put a lid on my brew kettle and leave it alone until the next morning. I transfer to a bucket, move it to my cooler, add yeast and put on an airlock.

rancocas

Active Member

I would not advise it. You risk burning out your compressor.

I also don't remember having that kind of almond flavor, and as for the oxygen in the wort, I don't oxidize the wort before the pitch yeast so that it uses up that excess oxygen, if there is any. I use a plastic fermenter and therefore cool the wort in a stainless steel pot (by evaporation without stirring) below 70'C so that there is no impact on the plastic.

Just finished my first no chill in a corney keg. Put the keg in a bucket of cold water and filled directly after flame out. Left the dip tube in place, don't want to deal with that later.

Lower rubber didn't seam to absorb much heat, placed in the garage now to chill.

Went to add gas to prevent excessive vacuum. Had a beer QD on my spare manifold line, but that was no problem as I was only sealing. Once I removed the QD, the beer post popit got stuck sideways and shot beer to the top of my garage and everywhere else. Didn't loose much as I slapped that QD back on and vented pressure via pressure release valve.

Moral of my story, I now expect this beer to turn out fantastic!

Lower rubber didn't seam to absorb much heat, placed in the garage now to chill.

Went to add gas to prevent excessive vacuum. Had a beer QD on my spare manifold line, but that was no problem as I was only sealing. Once I removed the QD, the beer post popit got stuck sideways and shot beer to the top of my garage and everywhere else. Didn't loose much as I slapped that QD back on and vented pressure via pressure release valve.

Moral of my story, I now expect this beer to turn out fantastic!

CyberFox

Well-Known Member

- Joined

- Mar 29, 2022

- Messages

- 230

- Reaction score

- 100

It's good to hear that no-chill is alive and well. I've been thinking of leaving the wort in the kettle to chill overnight instead of using a cube and it's good to know that it works for others. Can't get any easier than that and I'm all about keeping the brew day quick and easy. I streamlined my process for my last batch: 45 minute mash with no sparge, 45 minute boil, then throw in flameout hops and let chill overnight. Makes for a short and easy brew day. My latest beer is ready to try tomorrow. I left 6 ounces of hops in the cube overnight to act as a hop stand, so here's hoping that it turns out as intended. Happy Holidays to everyone!

It’s supposed to drop to single digits here in a few hours. I’m definitely no-chilling today! I’ll set my Chugod thermo for 68F and leave the pot outside the garage door.

Keep us posted! I am interested in hearing how it turns out. This is close to what I am currently doing.It's good to hear that no-chill is alive and well. I've been thinking of leaving the wort in the kettle to chill overnight instead of using a cube and it's good to know that it works for others. Can't get any easier than that and I'm all about keeping the brew day quick and easy. I streamlined my process for my last batch: 45 minute mash with no sparge, 45 minute boil, then throw in flameout hops and let chill overnight. Makes for a short and easy brew day. My latest beer is ready to try tomorrow. I left 6 ounces of hops in the cube overnight to act as a hop stand, so here's hoping that it turns out as intended. Happy Holidays to everyone!

cgriffith

Well-Known Member

Can you expand on this comment please. I was planning on doing this when I finally get around to building my temp controller, but want to understand your point.I would not advise it. You risk burning out your compressor.

He just means that the refrigerator compressor would be running constantly for a long time (hours) to cool the beer from boiling temps to yeast pitching temps. I would, at least, just let it sit outside the refrigerator to cool down to closer to room temperatures before you put the refrigerator to work.Can you expand on this comment please. I was planning on doing this when I finally get around to building my temp controller, but want to understand your point.

The way I look at "no chill" is that it works fine as long as you make every possible effort to avoid contamination of the sanitized (ie. boiled) beer. The whole point of chilling fast and pitching the yeast quickly is that you are reducing the risk of infection by shortening the vulnerable period of time between boiling and fermentation when alcohol becomes present in the beer to reduce infection risk. No chill carries some risk although you can reduce this with good technique.

- Joined

- Dec 21, 2012

- Messages

- 355

- Reaction score

- 473

My fermenter is a chest freezer. I wouldn't want to risk it, so I let the wort cool to pitching temps before transfer, yeast and storage.Could you just put the fermenter straight in the cooler and let it chill that way? Edit ( I have a SS fermenter that i put in a chest freezer)

- Joined

- Dec 21, 2012

- Messages

- 355

- Reaction score

- 473

I have a chiller, and used it for a few years. I used the runoff to water plants, but still felt like it was wasting too much water. I switched to using pool water to chill until the pool died, and then switched to full no-chill.I was pretty much exclusively no-chill for years until just a few batches ago when I got an electric AiO that came w/ an immersion chiller (Klarstein Maischfest)...

I would put the kettle in the sink for a couple sink-fulls of water... until it was cool enough to carry outside w/out fear of scalding myself. Then

overnight-chill in the kettle w/ lid clamped on. Transfer to bucket the next day (12-18 hrs depending on outside temps.) then into swamp cooler with frozen water bottles until pitching temp.

Worked quite well.

Never did do the full Aussie no-chill in the cube... Only overnight in the kettle for me.

CyberFox

Well-Known Member

- Joined

- Mar 29, 2022

- Messages

- 230

- Reaction score

- 100

My beer turned out pretty damn good. Throwing the hops in the cube to act as a hop stand worked exactly as I'd hoped. I purposely omitted the dry hop to see what a 6 oz hop stand would do by itself. There's plenty of hop flavor, but very little aroma (as I figured). I'm surprised at how much flavor I'm getting from the grain also. I used 100% Rahr 2-row, so I'm not sure if the extra flavor is from the Rahr or from doing no sparge (maybe both?). I definitely think it needs dry hopping to bring it to the next level, but it's still plenty good without it. I think that, due to the hops being added close to flameout temperature, the bitterness could possibly become a bit much depending on the hop used. I used 0.5 oz of Warrior at the beginning of the boil and 6 oz of Cascade at flameout and the bitterness isn't overwhelming, but it's pretty solid. I can imagine that if I substituted Cascade with Chinook, the bitterness might get out of control. For my next beer, I'm planning to do a 6 oz hop stand at 170 degrees (to limit the bitterness, especially since dry hopping will add a bit extra) and a 6 oz dry hop. My streamlined process (shorter mash and boil, no sparge, and no-chill) is definitely here to stay.Keep us posted! I am interested in hearing how it turns out. This is close to what I am currently doing.

Last edited:

I think that, due to the hops being added close to flameout temperature, the bitterness could possibly become a bit much depending on the hop used. I used 0.5 oz of Warrior at the beginning of the boil and 6 oz of Cascade at flameout and the bitterness isn't overwhelming, but it's pretty solid. I can imagine that if I substituted Cascade with Chinook, the bitterness might get out of control. For my next beer, I'm planning to do a 6 oz hop stand at 170 degrees (to limit the bitterness, especially since dry hopping will add a bit extra) and a 6 oz dry hop. My streamlined process (shorter mash and boil, no sparge, and no-chill) is definitely here to stay.

Most of what you read is that the hop schedules should be shifted at least 20 minutes for no-chill.. I think it should be more. Way more. I dumped a batch because I didn't move my hop additions enough and it was way too bitter.. After a couple of weeks in the keg it seemed to soften but realistically it wasn't going to get consumed.

I am about to try an all simcoe recipe that includes a 200 minute hopstand at 185 and a huge dry hop. Should be interesting.

0.3 oz (8 IBU) — Simcoe 12.4% — Boil — 15 min

0.5 oz (8 IBU) — Simcoe 12.4% — Boil — 0 min

1 oz (15 IBU) — Simcoe 12.4% — Aroma — 200 min hopstand @ 185 °F

6 oz — Simcoe 12.4% — Dry Hop — day 5

CyberFox

Well-Known Member

- Joined

- Mar 29, 2022

- Messages

- 230

- Reaction score

- 100

I've also heard about shifting the hops 20 minutes to adjust for bitterness with no-chill. I think the cooler hop stand should definitely keep the bitterness at bay. Now my main dilemma is figuring out how to transfer more efficiently while doing a big dry hop. Currently, I do a closed transfer by injecting just enough CO2 into my carboy to transfer the beer through a racking cane into the keg through the liquid post. Dodging a big, loose dry hop with the racking cane can be a pain. One option is using a bag, but that supposedly results in less extraction. If I were to use a spigot instead of a racking cane, I could still run into problems with a stuck transfer. It's a hard problem to solve.Most of what you read is that the hop schedules should be shifted at least 20 minutes for no-chill.. I think it should be more. Way more. I dumped a batch because I didn't move my hop additions enough and it was way too bitter.. After a couple of weeks in the keg it seemed to soften but realistically it wasn't going to get consumed.

I am about to try an all simcoe recipe that includes a 200 minute hopstand at 185 and a huge dry hop. Should be interesting.

0.3 oz (8 IBU) — Simcoe 12.4% — Boil — 15 min

0.5 oz (8 IBU) — Simcoe 12.4% — Boil — 0 min

1 oz (15 IBU) — Simcoe 12.4% — Aroma — 200 min hopstand @ 185 °F

6 oz — Simcoe 12.4% — Dry Hop — day 5

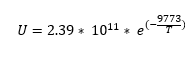

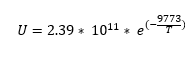

I just did a no boil beer with only a 15 minutes hopstand for bittering. I used about 1.5g/l high alpha hops andit easily reached the desired 30 ibus within 15 minutes. It actually tastes like I even overshot a bit and reached something in between 35 and 40 Ibus. After seeing this, I think that the no chill additions must be pretty powerfull. Given the extended time, they are probably more like 45 - 60 Minutes boil additions. I found that the suggested utilisationfactors in this article here are pretty close for hopstands and can be probably used for no chill as well:

https://help.grainfather.com/hc/en-us/articles/360014527537-Calculation-IBU

Quote:

Our approach using the Tinseth/Rager/Garetz/Daniel equations for predicting IBUs for post-boil hops is as follows:

T = Temperature in Kelvin

As you can see, at 90C, there is still about 50% utilisation. Let's say, during the first hour it chills from 100C to 85 C, that would mean theres probably already 60-80% utilisation, compared to a boil. Then add the extra hours afterwards between 85C and 60C and the difference between a 60 minute boil and a no chill batch becomes neglectable.

https://help.grainfather.com/hc/en-us/articles/360014527537-Calculation-IBU

Quote:

Our approach using the Tinseth/Rager/Garetz/Daniel equations for predicting IBUs for post-boil hops is as follows:

T = Temperature in Kelvin

| Temperature | Utilisation Factor (U) |

| 90°C (194 F) | 49% |

| 80°C (176 F) | 23% |

| 70°C (158 F) | 10% |

| 60°C (140 F) | 4.3% |

| 50°C (122 F) | 1.75% |

As you can see, at 90C, there is still about 50% utilisation. Let's say, during the first hour it chills from 100C to 85 C, that would mean theres probably already 60-80% utilisation, compared to a boil. Then add the extra hours afterwards between 85C and 60C and the difference between a 60 minute boil and a no chill batch becomes neglectable.

Similar threads

- Replies

- 53

- Views

- 2K

- Replies

- 4

- Views

- 326

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)