Abdul Muhamed

Well-Known Member

- Joined

- Oct 20, 2024

- Messages

- 75

- Reaction score

- 56

Sorry, Typo...It finished at 1.010 specific gravity meaning it had a starting gravity of 1.064 and final of 1.010. This indicates ABV of 7%. I was sure it had finished fermentation. I fixed the typo to prevent confusion. Yeast was S 04 and it fermented 11 days. I got 3 consecutive readings of 1.01 so I was confident it was done.1.010 perhaps (and hopefully)?

Measured with a calibrated hydrometer that reads 1.000 in plain water, at calibration temp?

What yeast did you use?

How long had it been fermenting?

Have you read How to Brew 4th Ed. by John Palmer?

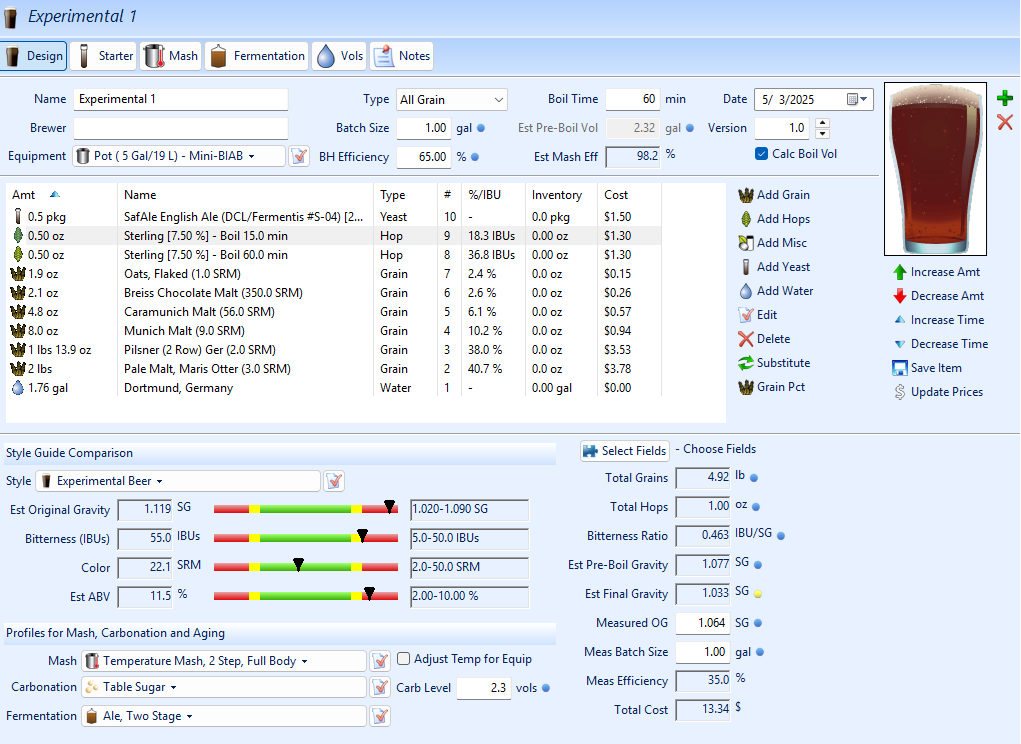

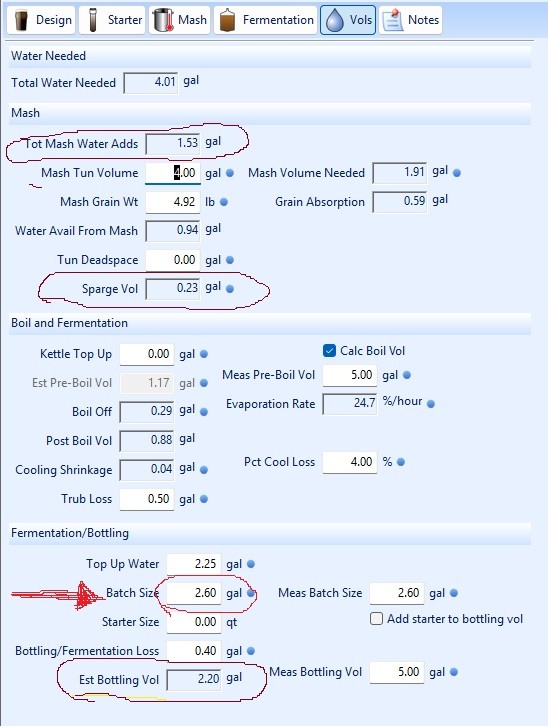

My confusion was reading the BrewSmith2 calculator on amount of water to add.

Last edited: