I'm definitely interested. I'll send you a message.

How do you measure the flow of oxygen?

With the regulator that works with disposables, there is no way to measure. The flow rate can be adjusted by how far you open the valve, but there are no settings showing flow rate. I would just crack it wide open and aerate for 60-90 seconds.

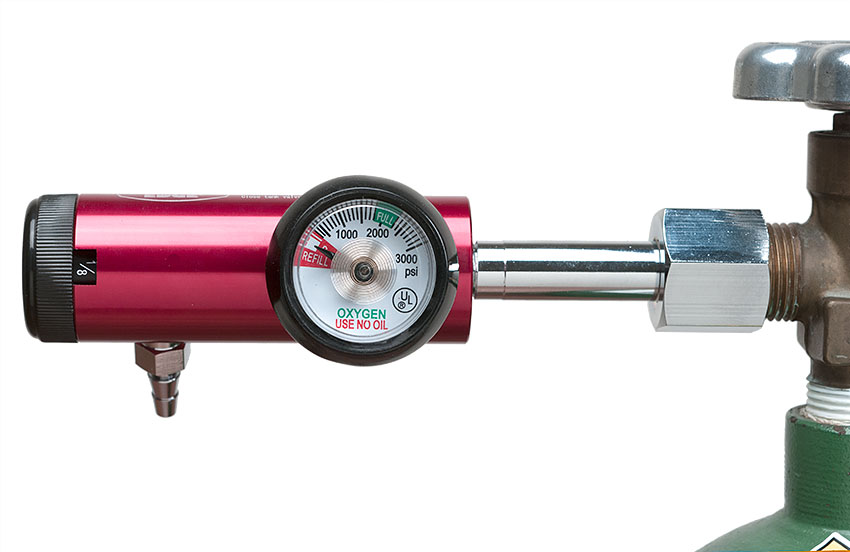

The Williams regulator has a dial that allows you to select flow rate, in liters/min. It ranges from 1/8 to 4 liters/min.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)