lzrdkng14

Well-Known Member

Hey guys,

Looking to do my first Electric Brew Control Panel build. Been on these forums off and on for a few years, but I have finally decided to take the plunge to electric!

My plan is to start with a Single PID Single Element system, with no pumps. Going to use a couple 5 gallon coolers for MT and HLT and heat all water in the BK. I would like to eventually add at least one pump and possibly put another element in the HLT, but I only have 30A to work with so can only run one heater at a time.

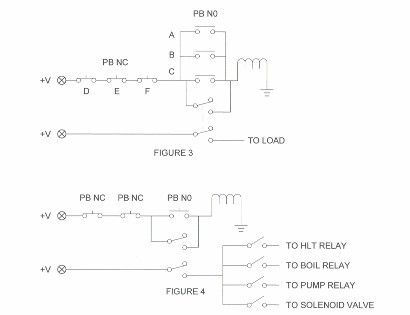

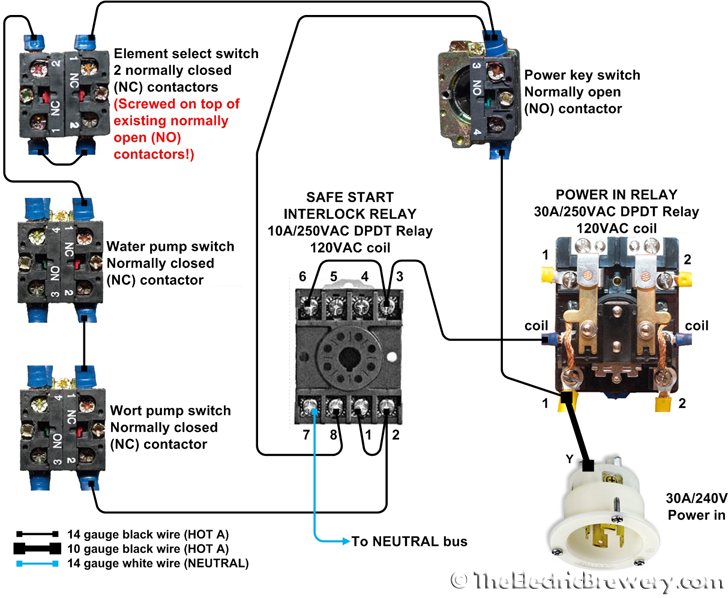

Using these diagrams as my inspiration for this design:

Auberin-wiring1-a4-4500w-BIAB-30d

Auberin-wiring1-a4-5500w-BIAB-30d6

But this controller will be slightly different than the above deisgns. I would like to use a key switch as a main power switch with a green LED. Will use a Red Illuminated push button switch to power the 5500 watt Element and a Yellow Illuminated push button switch to power the PID. Will also have an Emergency stop button to kill everything.

Here is my parts list:

Cantex 12x12x6 Box

Auber SYL-2352 PID

40a SSR

Heat Sink for SSR

Contactor

RTD Sensor 1/2 NPT 6 inch

Key Selector Switch - 2 NO

Green LED Indicator

Illuminated Pushbutton Switch - Red

Illuminated Pushbutton Switch - Yellow

Emergency Stop Button

So here is what I am looking for:

Looking to do my first Electric Brew Control Panel build. Been on these forums off and on for a few years, but I have finally decided to take the plunge to electric!

My plan is to start with a Single PID Single Element system, with no pumps. Going to use a couple 5 gallon coolers for MT and HLT and heat all water in the BK. I would like to eventually add at least one pump and possibly put another element in the HLT, but I only have 30A to work with so can only run one heater at a time.

Using these diagrams as my inspiration for this design:

Auberin-wiring1-a4-4500w-BIAB-30d

Auberin-wiring1-a4-5500w-BIAB-30d6

But this controller will be slightly different than the above deisgns. I would like to use a key switch as a main power switch with a green LED. Will use a Red Illuminated push button switch to power the 5500 watt Element and a Yellow Illuminated push button switch to power the PID. Will also have an Emergency stop button to kill everything.

Here is my parts list:

Cantex 12x12x6 Box

Auber SYL-2352 PID

40a SSR

Heat Sink for SSR

Contactor

RTD Sensor 1/2 NPT 6 inch

Key Selector Switch - 2 NO

Green LED Indicator

Illuminated Pushbutton Switch - Red

Illuminated Pushbutton Switch - Yellow

Emergency Stop Button

So here is what I am looking for:

- Will these parts all work together? (Specifically the Key Selector and E-Stop as they are variances to the above drawings)

- Is there an existing drawing/design that is the same as what I am doing? I have searched but did not find one...

- Will this design facilitate expansion later on?

Last edited: