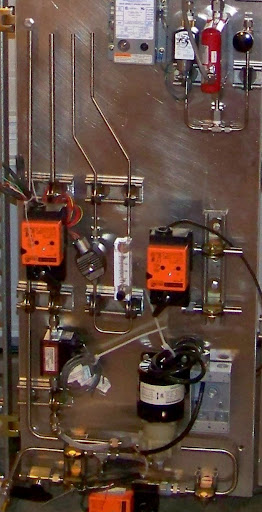

Here are a couple pictures of new components for the phase 2 brewery project, 1"OD outer tube with 1/2" SS inner tube CFC, O2 mixer, water heater/steam boiler. Chiller inside tube is 20 foot length of 1/2" OD .049 316 tubing inside a 1"tube with inner tubing silver brazed to modified swagelok fitting. Boiler is 4-20' lengths of 1/4" OD SS tubing wound over a 2" PVC pipe and coupled to a modified1/4"tube cross for water in at bottom and steam out the top. http://picasaweb.google.com/kevin.ladue/NewBrewingGadgets/photo#5164076763824483858

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)