Sorry to dig up an old thread, but could you point me in the right direction for how you converted your AC unit to a glycol chiller?

As I look at the pictures, much of it is there. I can add a few more. The key is, the A/C unit coils on the front, the ones the air is circulated across to cool the room, are submersed.

Here, I cut a slot in the side of the large cooler to accommodate the piping for the coil. If you can help it, and I mean really avoid it like the plague, don't cut or modify the coil, aside from bending.

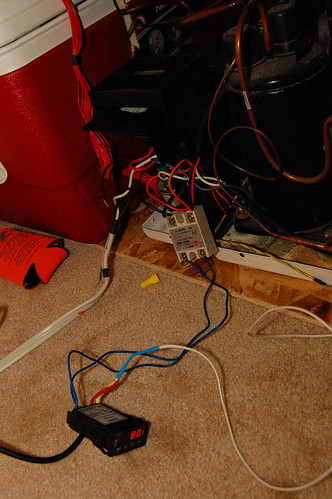

Proof that its a working. Have to love that Texas humidity. Not the digital controller in the left. That's told temperature controller, as part of the room cooler.

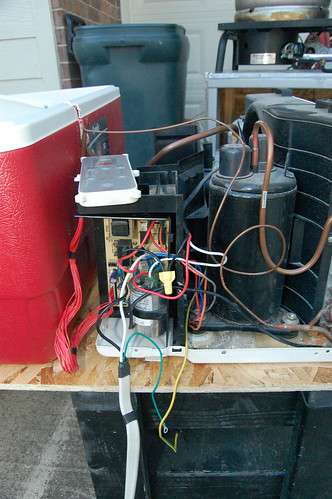

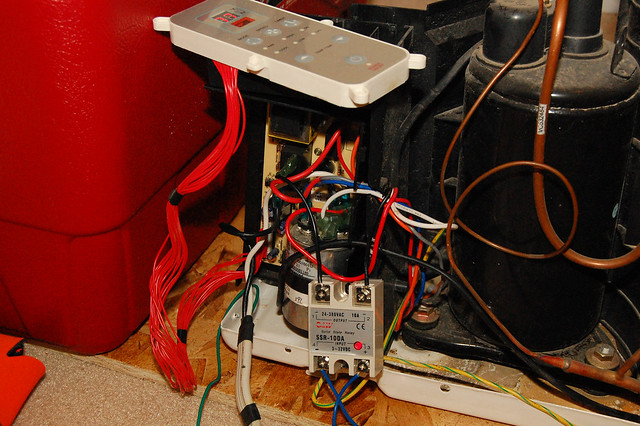

When I dug deeper, I found the starter. The round thing in front is a large capacitor try to not get to friendly with it. Its needed, and it STORES energy. But behind the capacitor there is a black box, that's the starter relay. I bypassed this, and tied it into my SSR that talks to the Fermtroller unit.

Fermtroller is then programmed to not turn on if it has been on in the last 5 minutes or so. A/C motors don't like being turned on and off rapidly.

Another look. Still have the old controller on it.

Long before everything.

You can kinda see the bypass here. This was the initial test of the relay. I have the A/C controller ON, and therefore was able to determine the black boxes purpose. Once I removed the A/C controller, I by passed the built on relay.

SSR doing to work. Was replaced with Fermtroller. Hope to someday have 4 conicals in my garage... As soon as Stout Tanks gets REAL cheap, like going out of business cheap. In all honesty... a few more years.

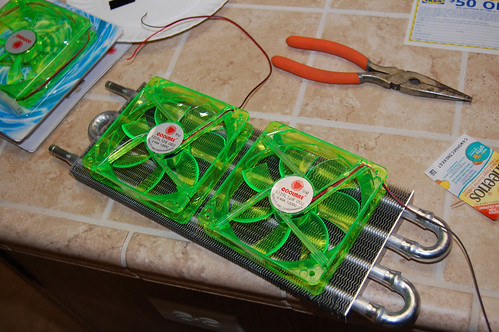

The cooling units inside my temp controlled boxes. This is a transmission oil radiator with 2 120mm 12v fans on it. I have them pulling the air across the radiator, with a the temperature probe on the back side measuring the ambient temperature.

The makings of a fine box.

Piano hinge

12v Valve. 1/2npt to 3/8 id tubing. Only had one problem early one, due to gunk in the lines.

Better shot of the valve.

I'm running Brewtroller's latest build. Version 2 was a huge leap from the original, took a phone call to the guys to get it working though, turned out a programming error (not mine) cost me 2 weeks of headaches. But it's been running flawlessly ever since.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)