Nessie

Active Member

Good day!

I'm making this thread to document my build process, hopefully it's in the right place.

Bit of background:

I have about two years of brewing experience, all extract. Got the itch to go all-grain from the moment I first read about it and have been working on the transition for the past year. I work in a technical field, so I'm familiar with drudging through manuals and spending hours researching before pulling any triggers. That being said, I am not very familiar with residential/civilian electrical work so bare with me.

The setup so far:

The vision is an electric HERMS brewery powered by a BCS 460. I have in my custody two 5500 watt ULWD heating elements, 3 80 QT kettles, 2 110vac Chugger pumps, a BCS 460, SSR's, temperature probes, various tri-clover fittings, ball valves, Hx's etc..

The kettles and fittings are off to the welder, so my focus is shifted to the control panel. I've been thumbing my way through several schematics and have a couple of ideas that I'd like to implement, though I am not sure if they are feasible and haven't been able to find a post that addresses the issue. So here I am, ready to air out my dirty.. dirty laundry.

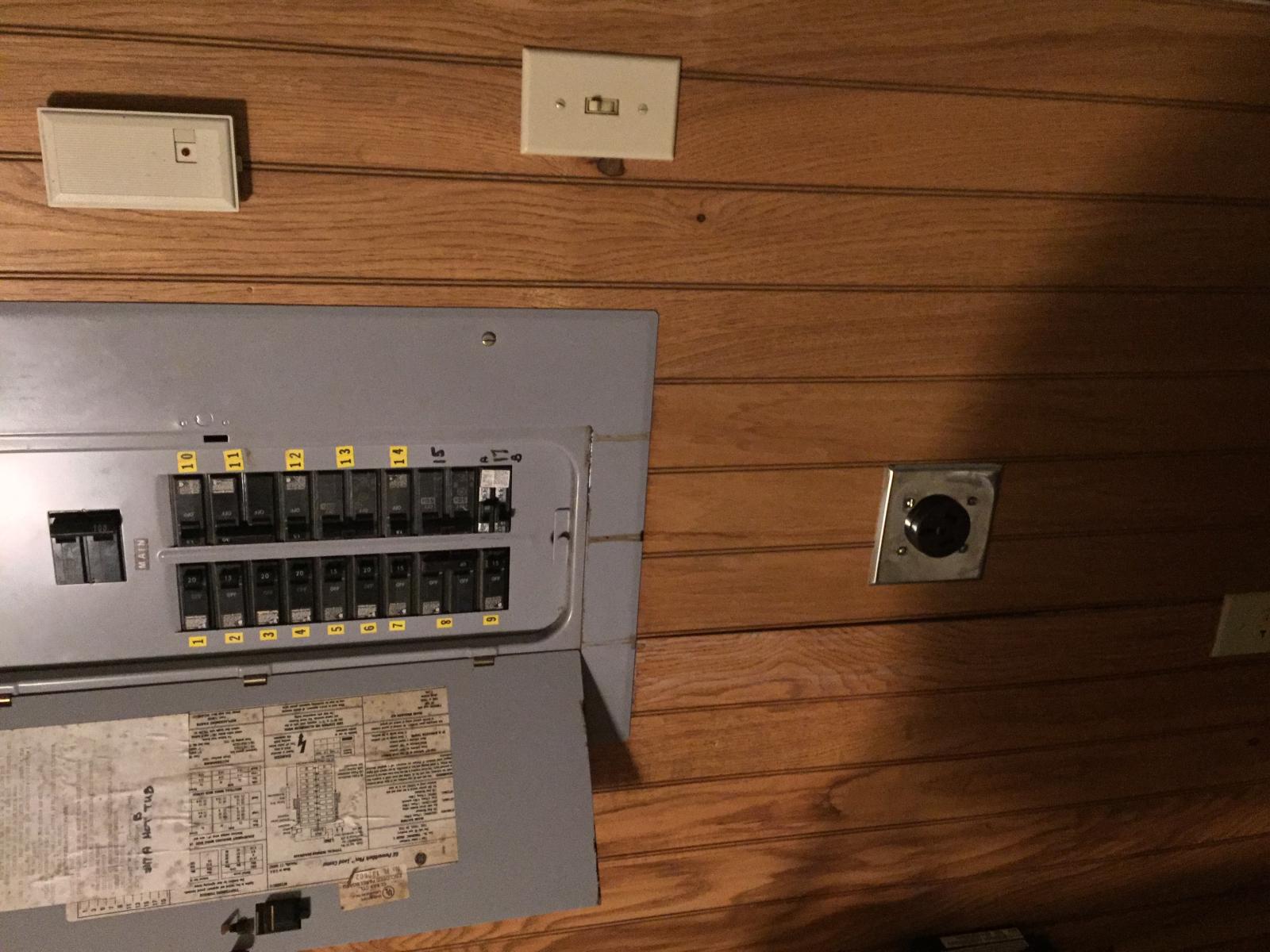

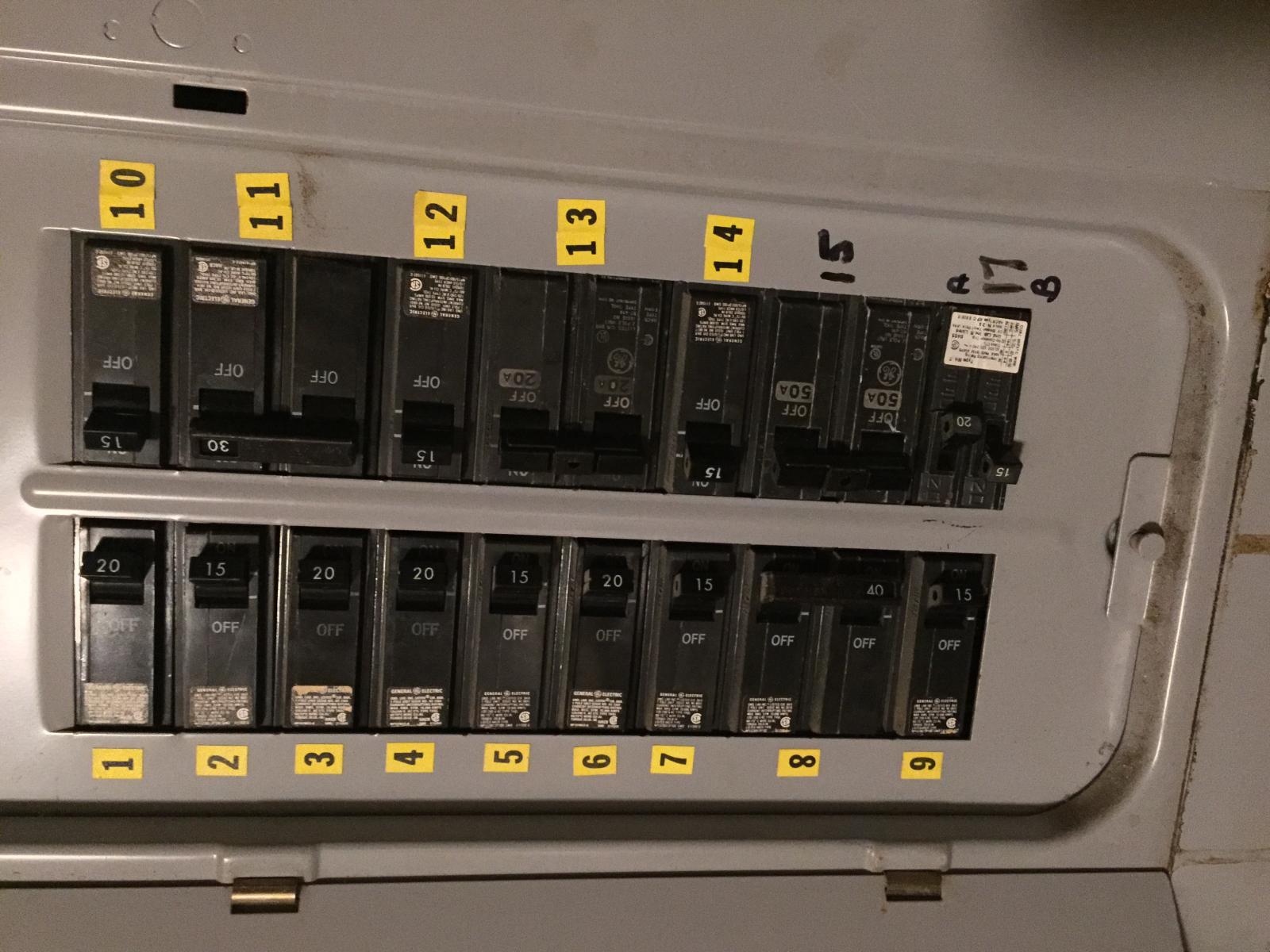

I have a 240vac outlet with a 50 Amp breaker ready to feed the panel, however it is split phase with a ground. So three wires, H-H-G, with the out of phase wires acting as the 'neutral' every half cycle (at least that's how I understand it).

What I'd like to do is ...

1) Have the 240vac feed a bus bar inside the panel and then transform it down to a 120vac bus bar(if that's possible/feasible) to supply power for the pumps. In my head this is the cleanest option, if you could retain the split phase properties during the transformation.

2) The other school of thought is that I could feed the 120vac bus bar with 1 leg of the 240vac bus, though essentially eliminating the neutral (and exposing gaps in my knowledge *gulp*).

3) Have multiple power sources, one 240vac and one 120vac from two separate outlets (not preferred) to feed two separate busses. Not clean, but it would work.

I have a bunch of pictures and some schematics that I will post in a bit.

Any help is appreciated!

I'm making this thread to document my build process, hopefully it's in the right place.

Bit of background:

I have about two years of brewing experience, all extract. Got the itch to go all-grain from the moment I first read about it and have been working on the transition for the past year. I work in a technical field, so I'm familiar with drudging through manuals and spending hours researching before pulling any triggers. That being said, I am not very familiar with residential/civilian electrical work so bare with me.

The setup so far:

The vision is an electric HERMS brewery powered by a BCS 460. I have in my custody two 5500 watt ULWD heating elements, 3 80 QT kettles, 2 110vac Chugger pumps, a BCS 460, SSR's, temperature probes, various tri-clover fittings, ball valves, Hx's etc..

The kettles and fittings are off to the welder, so my focus is shifted to the control panel. I've been thumbing my way through several schematics and have a couple of ideas that I'd like to implement, though I am not sure if they are feasible and haven't been able to find a post that addresses the issue. So here I am, ready to air out my dirty.. dirty laundry.

I have a 240vac outlet with a 50 Amp breaker ready to feed the panel, however it is split phase with a ground. So three wires, H-H-G, with the out of phase wires acting as the 'neutral' every half cycle (at least that's how I understand it).

What I'd like to do is ...

1) Have the 240vac feed a bus bar inside the panel and then transform it down to a 120vac bus bar(if that's possible/feasible) to supply power for the pumps. In my head this is the cleanest option, if you could retain the split phase properties during the transformation.

2) The other school of thought is that I could feed the 120vac bus bar with 1 leg of the 240vac bus, though essentially eliminating the neutral (and exposing gaps in my knowledge *gulp*).

3) Have multiple power sources, one 240vac and one 120vac from two separate outlets (not preferred) to feed two separate busses. Not clean, but it would work.

I have a bunch of pictures and some schematics that I will post in a bit.

Any help is appreciated!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)