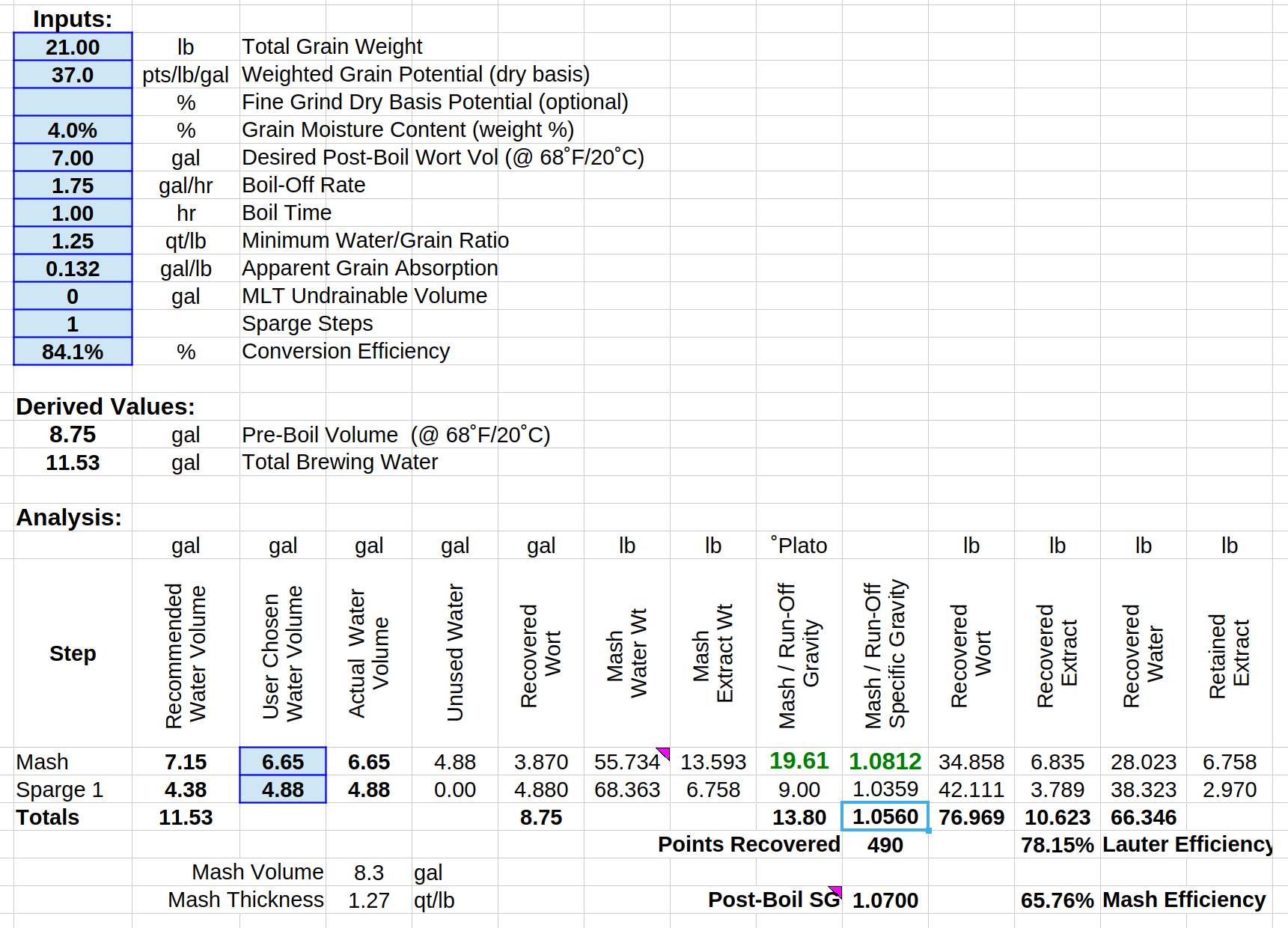

OK, with a pre-boil of 1.056 things look better efficiency wise, and the pre and post-boil SG are a lot more self consistent, but still not matching up quite as well as they should.Ok, I think I mixed up numbers of the two sessions I did this weekend. For this batch, I actually didn't get a post mash SG. Just a pre-boil SG of 1.056. So, I think that'll explain the numbers mixup.

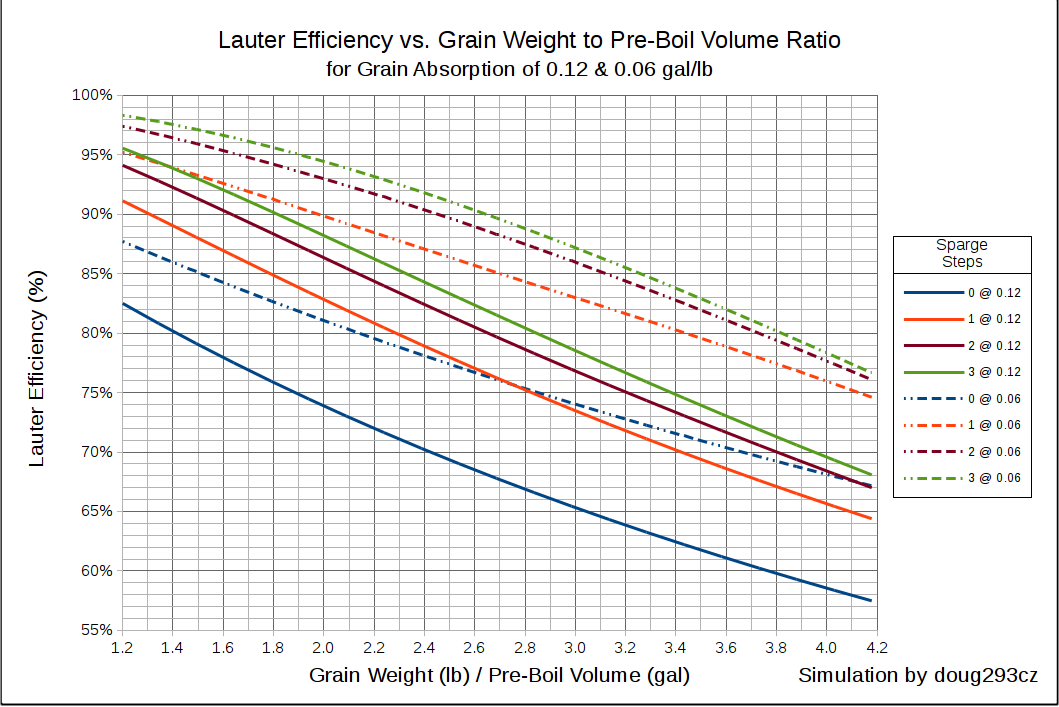

For my the batch Sunday, I was more focused on SG throughout the mash, and also did a no sparge. Just added 8.9 gal of strike water to the MT and did it no sparge. Much easier, and probably only lost a pt or two. However, I also did direct fire recirculation for that batch, and could've denatured the enzymes too. Got the same brewhouse eff of 57% w/ no sparge.

The predicted post-boil for your measured pre-boil SG & volume and post-boil volume is coming in a bit below your measured OG - 1.070 vs. 1.074. This indicates that there are some unidentified measurement errors. The most likely error is your pre-boil SG being somewhat lower that actual due to incomplete mixing of the first runnings wort and the sparged wort. It this in indeed the case, then your actual conversion efficiency was higher than 84%.

Brew on

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)