gifty74

Well-Known Member

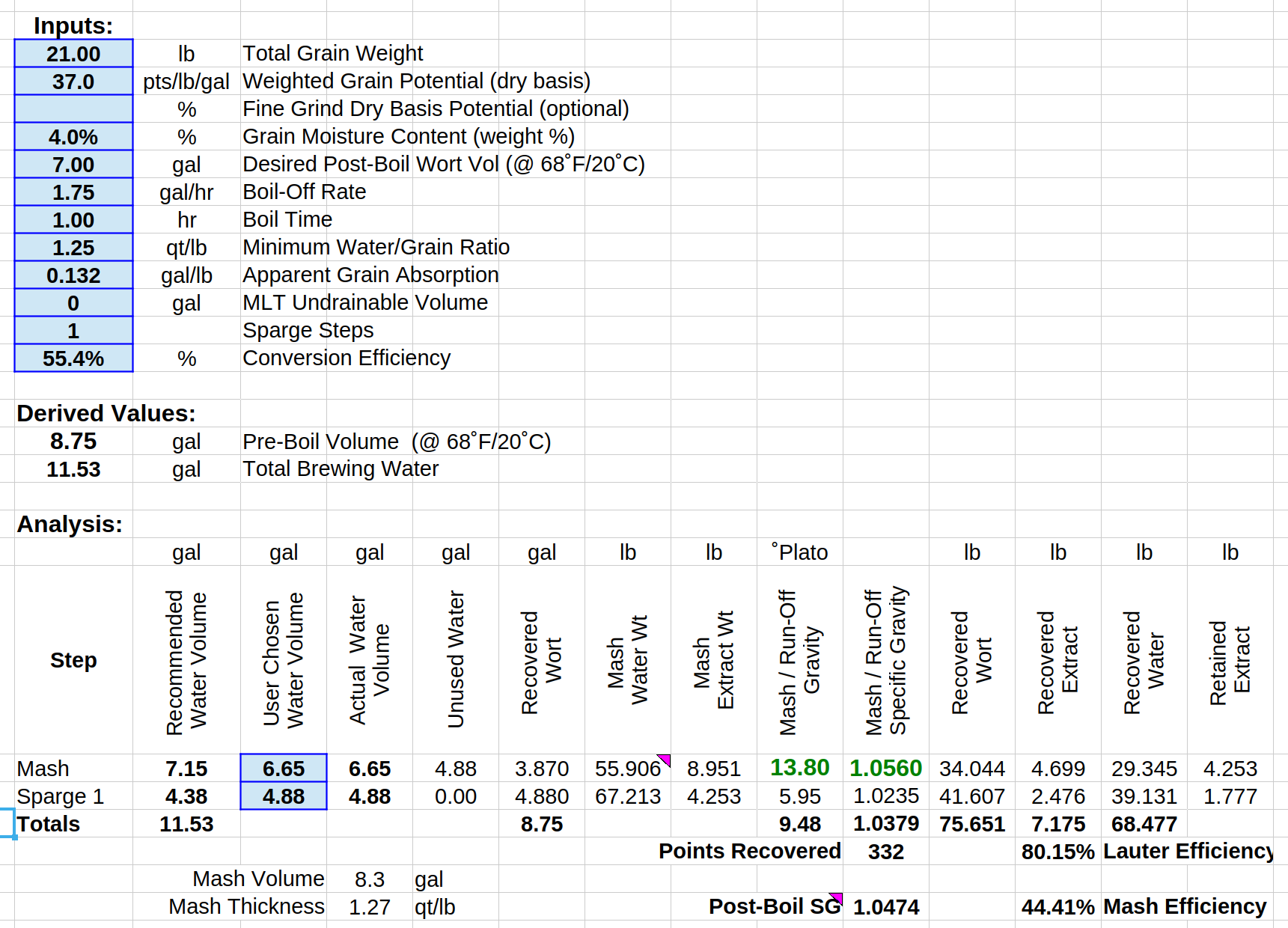

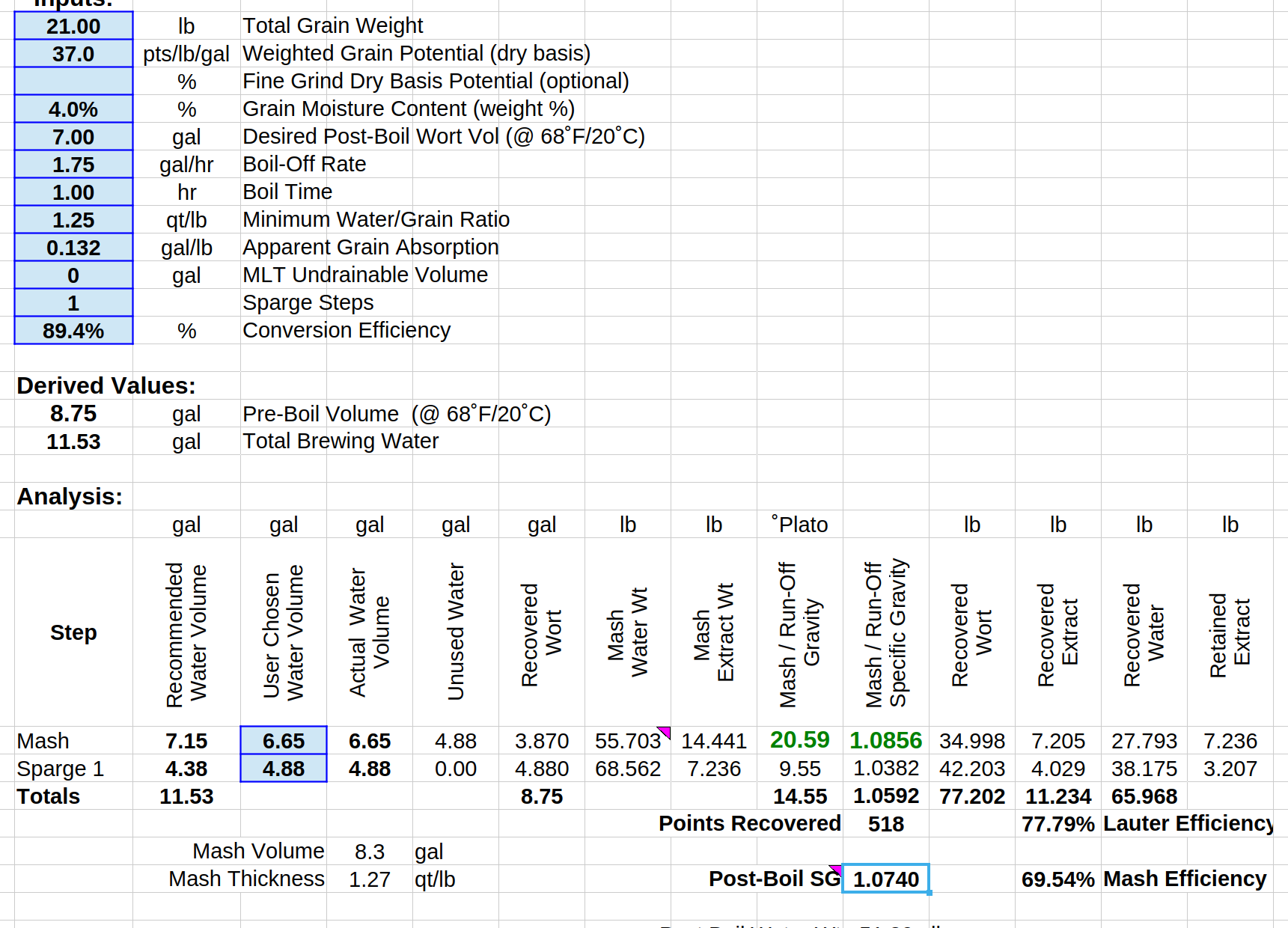

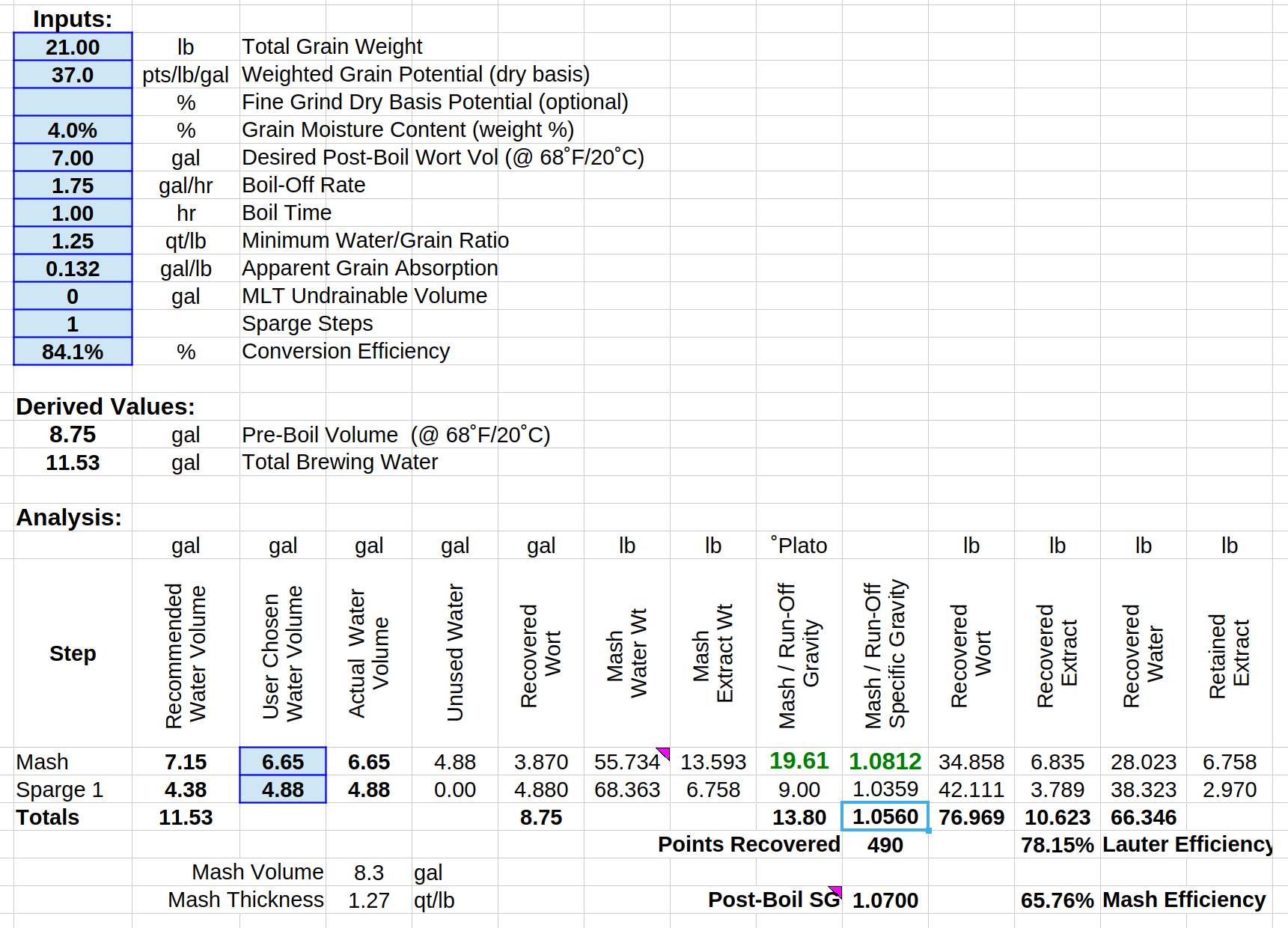

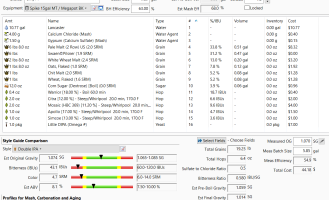

Long time all-grain brewer. Using Beersmith 3. Have a recirculating infusion mash setup. Have a good 3 roller mill, and am hyper focused on the crush, recently making it finer. My spike mash tun has a great false bottom and can go pretty fine, finer than most I've seen. So I do not think crush is the culprit. But I had been getting a brewhouse efficiency around 62%, and these past few batches I've been coming up short, even with that very conservative efficiency setting. Today had it set for 64%, and ended up getting 56%. Not sure what is going on. Today was pretty spot on for everything. 2.5lbs of wheat malt that I crushed super fine to almost a flour, and then the mix of 2 row and Pils was crushed pretty fine as well.

Recipe attached.

Just looking for some insight on why I constantly see efficiencies in the 70's, and i can barely get into the low 60's, with a focus on crush (studying pics online, comparing, etc), and a pretty good constantly recirculating infusion mash setup. I batch sparge, because I have that down pretty well. I know fly sparging will get me a few more points, but not sure i want the extra time involved. Shouldn't I be getting better eff with my batch sparge setup? Any other tips?

Recipe attached.

Just looking for some insight on why I constantly see efficiencies in the 70's, and i can barely get into the low 60's, with a focus on crush (studying pics online, comparing, etc), and a pretty good constantly recirculating infusion mash setup. I batch sparge, because I have that down pretty well. I know fly sparging will get me a few more points, but not sure i want the extra time involved. Shouldn't I be getting better eff with my batch sparge setup? Any other tips?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)