phreaky

Well-Known Member

Thanks @phreaky , that helps. If I were designing a control system completely from scratch, I'd directly leverage the proportional part of the loop (replace the solenoid with a valve.) I'd also use a loop in a loop (with a separate recirc pump) for the fermenters. I doubt however that most people would want the expense of such a system.

Thinking about how the existing loops (both digital and cooling) could be leveraged, let me throw this out there. We can add filters and controls to the system or the circuit. I'd suggest (greatly) restricting the flow of the pseudo-loop to the fermenter. That would reduce the impact of the glycol influx since we have such a large thermal mass I think that's appropriate. Then using the beer mode would be more viable.

Having just dug a little bit into the control code, it's apparent that we would want to keep the timers and fail-safes. This is an extremely mature system, and creating a new control system to do the same thing would be risky. The less anyone has to mess with it, the less chance of an unforeseen issue. Glycol users will never have the numbers that regular fridge users have, so as a corollary there's going to be less testing and a higher potential for failure.

(I've been typing this for an hour so there's a fair change there's 15 replies since I started)

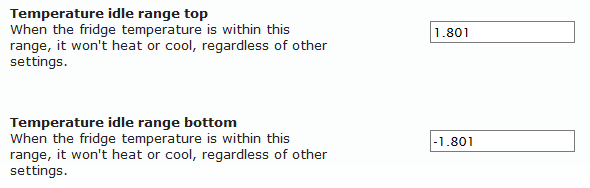

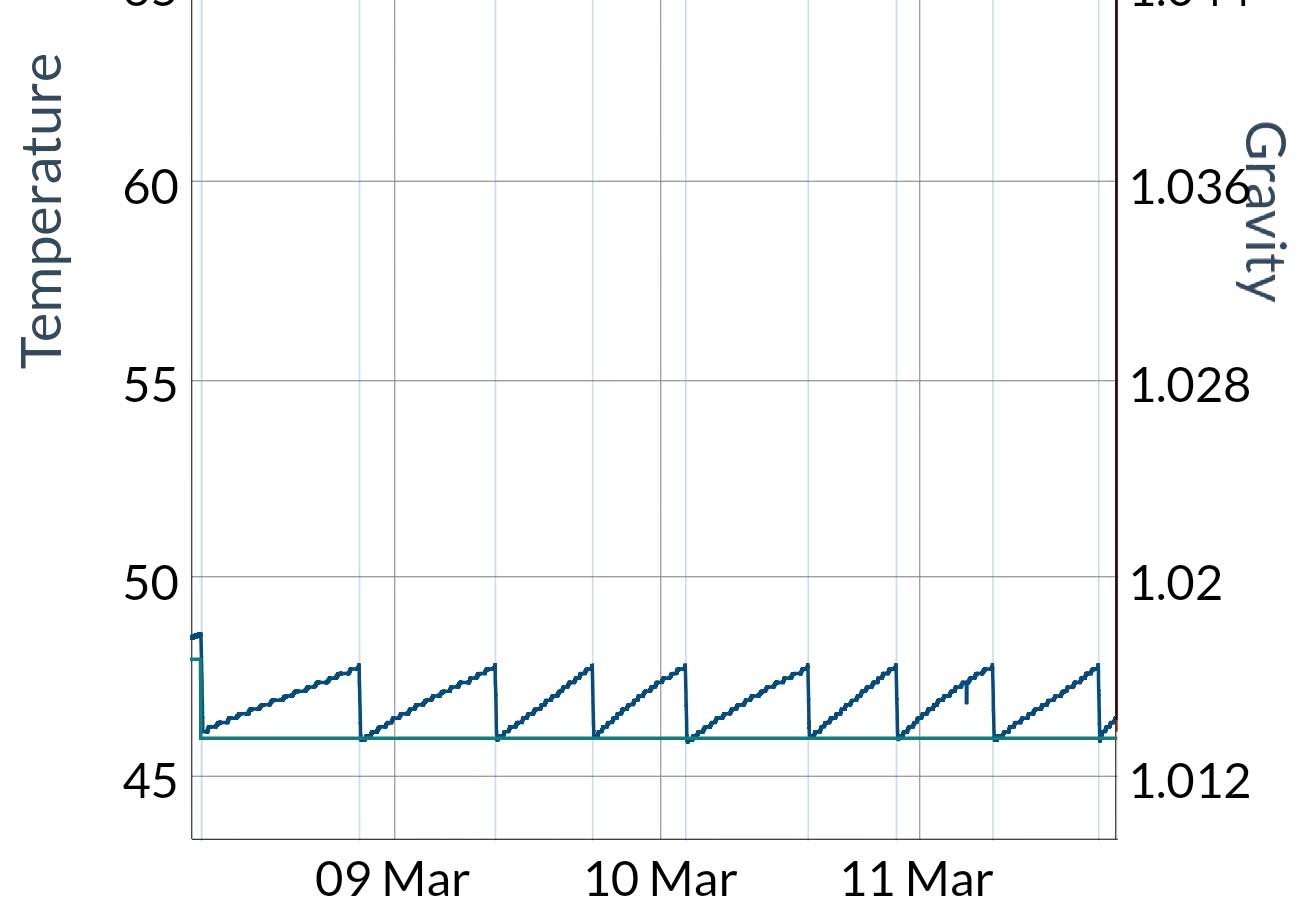

Honestly, I think the control logic works fine. It never really overshoots, and if it does, it's by less than a degree. My only issue with it is that it waits so long to turn on. Being that it is a glycol loop and the compressor has it's own run controller, I'm not worried about short cycling, so if there was a place to tell it to not rise so far before opening the solenoid I would be great. As you can see, it only runs a couple times a day during active fermentation (more during cold crashing obviously). When it does run, it's only for about 10 minutes. If I could get a way to use only the beer probe, or use profiles for fridge mode, then I would be in business.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)