Here is the equiment i've been slowly collecting for my build.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

I don't think so. I read the link and it says he used a 1/3 HP Motor.

We use a 10" Schmidling mill and I'm very happy with that motor. You just have to know it's limits.

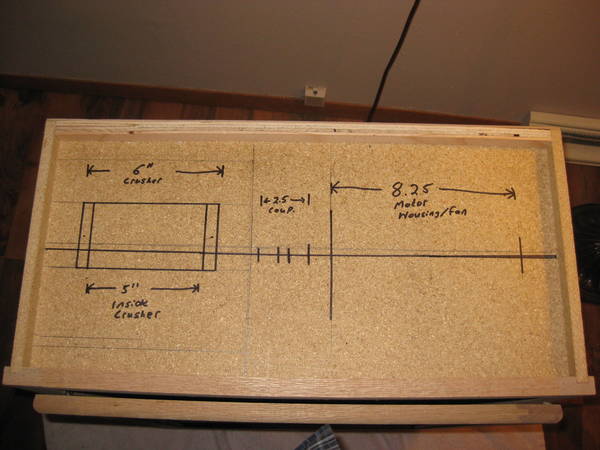

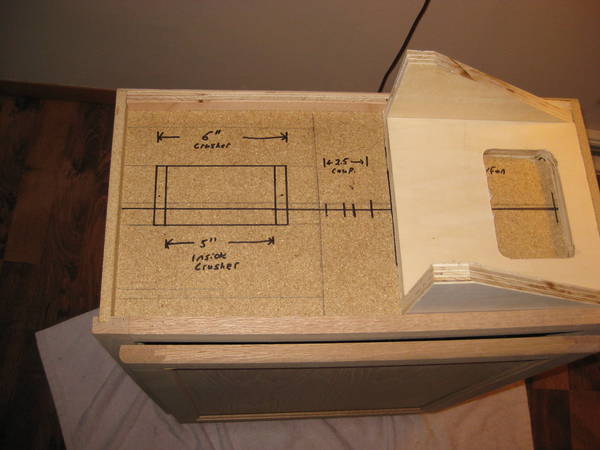

Using a Barley Crusher Mill:

Have the surplus center motor running at 177rpm.

Added 6" drive sprocket to 3" driven sprocket.

Result = Motor locks up with anything more that 1/2" deep of grain in mill.

Not happy.

Info on the motor please!

Ordered coupler from Mcmaster.

Will convert to direct drive from chain drive though this will cut our intended RPM by half; from 354 to 177.

Can't change sprockets because sprocket holes different sizes: Motor = 1/2", Mill = 5/16". Sending back to mcmaster.

What are the dimensions of the cabinet you are using?