ChemE

Well-Known Member

Like most good engineers I'm enthralled by efficiency. I think it is the mental challenge of trying to squeeze every last drop of performance out of a minimal amount of materials that appeals to me. One of my all time favorite engineering quotes is:

So motivation aside, I wanted to come up with the most efficient mash lauter tun I could. Design objectives were:

1) Accommodate 5 gallon all grain batches (except barleywine)

2) Provide good filter thickness even with low-gravity 2.25 gallon test batches

3) Minimize dead space so as not to reduce efficiency

4) Allow for fly sparging without exposing the mash to cold air

5) Allow for easy cleaning and maintenance

6) Rinse the grain bed as efficiently as possible in order to maximize efficiency

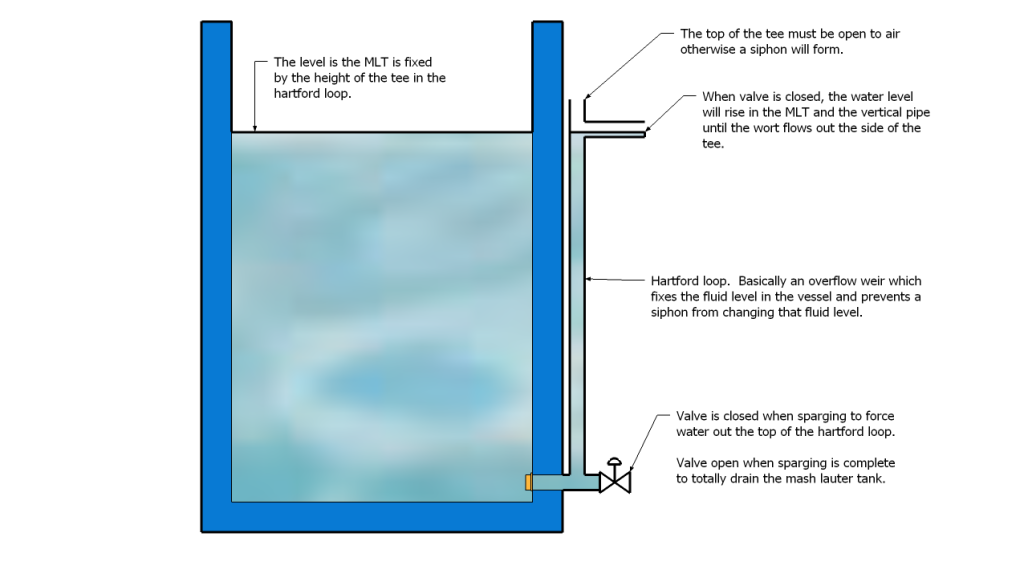

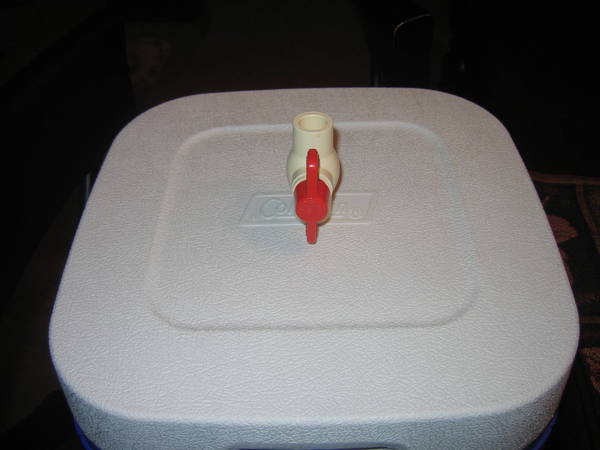

With my design objectives set, I went about educating myself and selecting a cooler which would meet my design constraints. How To Brew - Appendix D has some very good information on optimizing mash lauter tuns. I would have loved to have found a Coleman Xtreme or Ultimate Xtreme that fit the bill but these are all squat and wide. I really wanted something with a minimal footprint and good depth. My best option was a cheap no frills $20 cooler with questionable insulation shown below as the finished product.

The final product

I shot the lid full of great stuff and once it was dry, I cut the excess off and sealed the injection ports with white silicone caulk. This modification is nearly undetectable but helps the cooler maintain its temperature during mashing and sparging.

With that done, I set about making a copper manifold which would drain the cooler as close to completely as possible, maximized the number of slits, and minimized the distance that sugar from any one grain would have to travel to enter the manifold. This was the winning design. Nothing is soldered because there is absolutely no need and it would only complicate clean up at the end of the brew day.

Manifold as viewed from the top

Next order of business was coming up with a way to safely cut the slits very close together which was both neat and more importantly safe. After a few hours in the shop I came up with this jig for my jigsaw.

Jig used to cut slits in copper pipe

Jig in [simulated] action

Antoine de Saint-Exupéry said:A designer knows he has achieved perfection not when there is nothing left to add, but when there is nothing left to take away.

So motivation aside, I wanted to come up with the most efficient mash lauter tun I could. Design objectives were:

1) Accommodate 5 gallon all grain batches (except barleywine)

2) Provide good filter thickness even with low-gravity 2.25 gallon test batches

3) Minimize dead space so as not to reduce efficiency

4) Allow for fly sparging without exposing the mash to cold air

5) Allow for easy cleaning and maintenance

6) Rinse the grain bed as efficiently as possible in order to maximize efficiency

With my design objectives set, I went about educating myself and selecting a cooler which would meet my design constraints. How To Brew - Appendix D has some very good information on optimizing mash lauter tuns. I would have loved to have found a Coleman Xtreme or Ultimate Xtreme that fit the bill but these are all squat and wide. I really wanted something with a minimal footprint and good depth. My best option was a cheap no frills $20 cooler with questionable insulation shown below as the finished product.

The final product

I shot the lid full of great stuff and once it was dry, I cut the excess off and sealed the injection ports with white silicone caulk. This modification is nearly undetectable but helps the cooler maintain its temperature during mashing and sparging.

With that done, I set about making a copper manifold which would drain the cooler as close to completely as possible, maximized the number of slits, and minimized the distance that sugar from any one grain would have to travel to enter the manifold. This was the winning design. Nothing is soldered because there is absolutely no need and it would only complicate clean up at the end of the brew day.

Manifold as viewed from the top

Next order of business was coming up with a way to safely cut the slits very close together which was both neat and more importantly safe. After a few hours in the shop I came up with this jig for my jigsaw.

Jig used to cut slits in copper pipe

Jig in [simulated] action

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)