I have been using a two vessel system for the last year and it has been great. 15 gallon SS Brewtech kettle doubling as both HLT and Boil Kettle, and 13 gallon coleman extreme cooler for the mash.

My last brew this past winter was below 0° Celsius (32°F) outside and I decided I would build an electric BIAB system that I could use both inside my garage and outdoors weather permitting. It is not only the cold, it rains a heck of a lot here and indoors will help with that as well I would like the shorter brew day that I believe an eBIAB system will bring.

I will re-use my chugger pump from my old system, but I will probably leave the rest of it intact because it is likely better suited to brewing 10 gallon batches when I am in the mood for one.

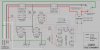

I will start off with my keggle build and move into adding the hardware, element and building the panel afterwards. No idea how long this build will take but I am sure I will learn a lot.

My last brew this past winter was below 0° Celsius (32°F) outside and I decided I would build an electric BIAB system that I could use both inside my garage and outdoors weather permitting. It is not only the cold, it rains a heck of a lot here and indoors will help with that as well I would like the shorter brew day that I believe an eBIAB system will bring.

I will re-use my chugger pump from my old system, but I will probably leave the rest of it intact because it is likely better suited to brewing 10 gallon batches when I am in the mood for one.

I will start off with my keggle build and move into adding the hardware, element and building the panel afterwards. No idea how long this build will take but I am sure I will learn a lot.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)