Making some good progress, finally ready to get back to brewing. I brazed up a triclamp temp probe for my BK (really my HLT but being used as a BK for now) and it is working great. The DS18B20 connected to some PTFE coated wire and potted inside with some heatsink compound.

You can click the pictures below for full size.

I haven't put it in an icebath or boiled it yet but it is keeping the same temps as my two other thermometers so I am not too concerned.

Last night I ran the system after working out some bugs the last few nights and I think it is ready to brew tonight, have 4 brews lined up for it this week.

Here is the patched together setup, the power control box is pretty much done but the HMI is basically just a box covering a computer and a microcontroller.

Touch panel is working great, here is what the GUI looks like right now. There are a lot of debugging items shown that will be removed as the SW matures.

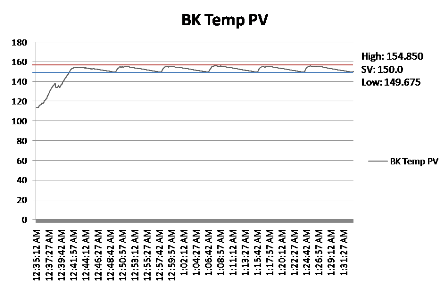

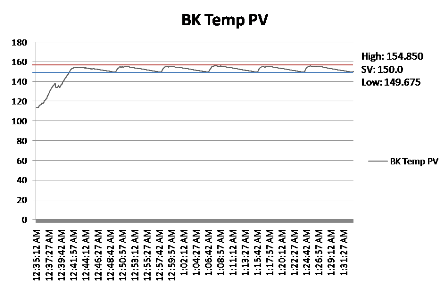

The PID loop needs to have some finer tuning, when set to 150 last night (or early this morning) it was able to stay between ~155 and 149.

The controller needs to lead a bit as the water temp continues to rise for a few degrees even after the element turns off. Still, it wasn't half bad for a wild guess at the parameters.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

Good luck!

Good luck!