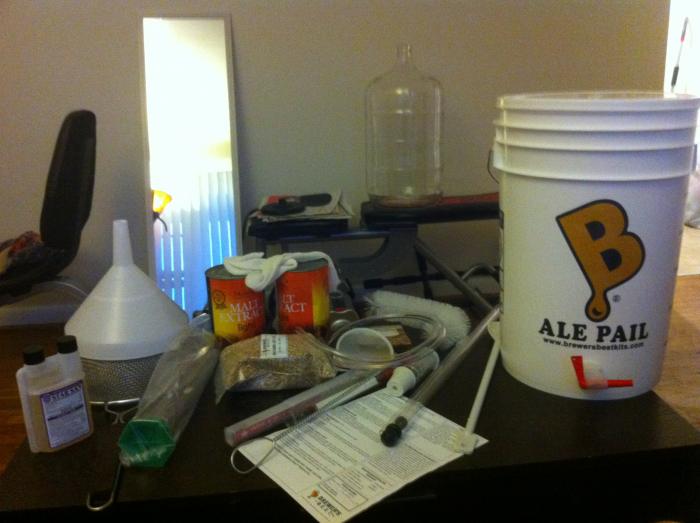

On the 17th I started my first batch of beer. I went out and grabbed all the gear I'd need from a local supplies store and chose a kit for American Pale Ale.

I was super excited when I got home and drove out to WalMart to get a big 22qt stock pot for steeping grains and boiling hops.

I cleaned my new pot thorougly and began sanitizing all my new equipment as I began heating the water. Once It reached the desired steeping temperature I dropped a bag of grains into the water to steep for the indicated amount of time.

*noob activity*I walked away from the pot and got distracted a little. The directions said not to allow the temp above 175F because of some tannins or some such. When I checked the temp some minutes later it was at 185F. I removed the pot from the burner and poured cold water into the pot immediately until the temperature went down. I paid more attention and got back on track.

After the grains steeped I removed them and started my boil. I then added the malt extract and the hops as instructed. It progressed as expected.

Once the boil was finished I set the pot into the sink and let the sink fill with cold water to cool down the beer.

*noob activity*I didn't really "get" the whole OG/FG hydrometer hoopla at the time, so I just dropped it into the beer and poured water in to see if the reading would change or whatever. The instructions really were not very... instructive about this step. I then said 'whatever' and took the hydrometer out and began pouring the beer into the carboy.

I poured the beer through a strainer and a filtered funnel. This was a grueling experience as there was so much mucky hops in there that i constantly had to stop and clean the filters. After I finally got all the beer into the carboy I thought it wasn't good enough, so I poured it BACK into the pot then poured it BACK through the filters and into the carboy again. (noob?)

*noob activity*Anyway, then I dumped a pouch of yeast into the carboy and plugged it was an airlock... I didn't really know how to use the airlock. The instructions didn't really give a very good tutorial. So, I filled the airlock with water almost completely and even filled the AIR TUBE with water. So, when placed in the carboy it was actually slowly dripping water back into the carboy from the water in the air tube. hee hee... heh.. hrm.

I woke up the next morning and felt a little guilty. Guilty about not knowing about the airlock and about not taking the OG reading seriously. So, I went on youtube and looked up a video about airlocks and set the airlock back up properly.

I then decided I would take a serious OG reading. I got a 100ml graduated cylinder in my beer kit that well didn't have any lines; it was just clear. So, I debated with myself for a while if you could actually call it a graduated cylinder if it didn't have markings then I realized I could easily use it to take the OG reading by just syphoning some of the beer out of the carboy into the cylinder and dropping in my hydrometer. I did this and got a reading of 1.049. It was within the 'beer' area on the hydrometer, so I figured this was fine. I still don't know if that's fine. The instructions really didn't say what it should read.

After pouring the test beer back into the carboy I sealed it up and stuck the thing in a closet. It has been in there for about 5 days now. After the first 24 hours in the closet it really started bubbling and foaming a lot. By now the bubbles come very slowly. Maybe every 20 seconds. I should time it maybe. Anywho, the foam is almost gone now and there is a lot of 'gunk' at the bottom of the carboy and on the sides of the upper part where the foam used to touch but now nothing touches it.

I'm worried about the gunk that is touching nothing but the air in the carboy. I don't know what it is exactly, but it was there sitting on top of and around the sides of the foam when there was foam. I hope it doesn't become moldy.

The actual beer looks fine otherwise. I've been reading these forums to find information about how to do the whole secondary fermentation step, but it seems like a lot of people don't bother and just leave it in the primary until it is time to bottle. So, I've decided to just leave it in the primary.

Thoughts?

I was super excited when I got home and drove out to WalMart to get a big 22qt stock pot for steeping grains and boiling hops.

I cleaned my new pot thorougly and began sanitizing all my new equipment as I began heating the water. Once It reached the desired steeping temperature I dropped a bag of grains into the water to steep for the indicated amount of time.

*noob activity*I walked away from the pot and got distracted a little. The directions said not to allow the temp above 175F because of some tannins or some such. When I checked the temp some minutes later it was at 185F. I removed the pot from the burner and poured cold water into the pot immediately until the temperature went down. I paid more attention and got back on track.

After the grains steeped I removed them and started my boil. I then added the malt extract and the hops as instructed. It progressed as expected.

Once the boil was finished I set the pot into the sink and let the sink fill with cold water to cool down the beer.

*noob activity*I didn't really "get" the whole OG/FG hydrometer hoopla at the time, so I just dropped it into the beer and poured water in to see if the reading would change or whatever. The instructions really were not very... instructive about this step. I then said 'whatever' and took the hydrometer out and began pouring the beer into the carboy.

I poured the beer through a strainer and a filtered funnel. This was a grueling experience as there was so much mucky hops in there that i constantly had to stop and clean the filters. After I finally got all the beer into the carboy I thought it wasn't good enough, so I poured it BACK into the pot then poured it BACK through the filters and into the carboy again. (noob?)

*noob activity*Anyway, then I dumped a pouch of yeast into the carboy and plugged it was an airlock... I didn't really know how to use the airlock. The instructions didn't really give a very good tutorial. So, I filled the airlock with water almost completely and even filled the AIR TUBE with water. So, when placed in the carboy it was actually slowly dripping water back into the carboy from the water in the air tube. hee hee... heh.. hrm.

I woke up the next morning and felt a little guilty. Guilty about not knowing about the airlock and about not taking the OG reading seriously. So, I went on youtube and looked up a video about airlocks and set the airlock back up properly.

I then decided I would take a serious OG reading. I got a 100ml graduated cylinder in my beer kit that well didn't have any lines; it was just clear. So, I debated with myself for a while if you could actually call it a graduated cylinder if it didn't have markings then I realized I could easily use it to take the OG reading by just syphoning some of the beer out of the carboy into the cylinder and dropping in my hydrometer. I did this and got a reading of 1.049. It was within the 'beer' area on the hydrometer, so I figured this was fine. I still don't know if that's fine. The instructions really didn't say what it should read.

After pouring the test beer back into the carboy I sealed it up and stuck the thing in a closet. It has been in there for about 5 days now. After the first 24 hours in the closet it really started bubbling and foaming a lot. By now the bubbles come very slowly. Maybe every 20 seconds. I should time it maybe. Anywho, the foam is almost gone now and there is a lot of 'gunk' at the bottom of the carboy and on the sides of the upper part where the foam used to touch but now nothing touches it.

I'm worried about the gunk that is touching nothing but the air in the carboy. I don't know what it is exactly, but it was there sitting on top of and around the sides of the foam when there was foam. I hope it doesn't become moldy.

The actual beer looks fine otherwise. I've been reading these forums to find information about how to do the whole secondary fermentation step, but it seems like a lot of people don't bother and just leave it in the primary until it is time to bottle. So, I've decided to just leave it in the primary.

Thoughts?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)