I recently finished reading the Vienna Lager book by Andreas Krennmair, which I highly recommend, and it inspired me to attempt a decoction in honor of the traditional brewing method. This recipe was adapted from one in the book, which represents a more modern interpretation of the style. I basically subbed Perle for Saaz because I love Perle.

I kept the grain bill simple with 9 pounds of Mecca Grade Vanora and 2 ounces of midnight wheat for a little color. Amber balanced water profile per Bru'n Water so I had to add 2 grams gypsum and 1.5 grams CaCl and some Campden to take out the chlorine, resulting in a mash pH of 5.41 15 grams of Perle first wort hop for a 70 minute boil and 21 grams in the whirlpool for 10 minutes at roughly 180 degrees. Fermented with 34/70 at 60 degrees.

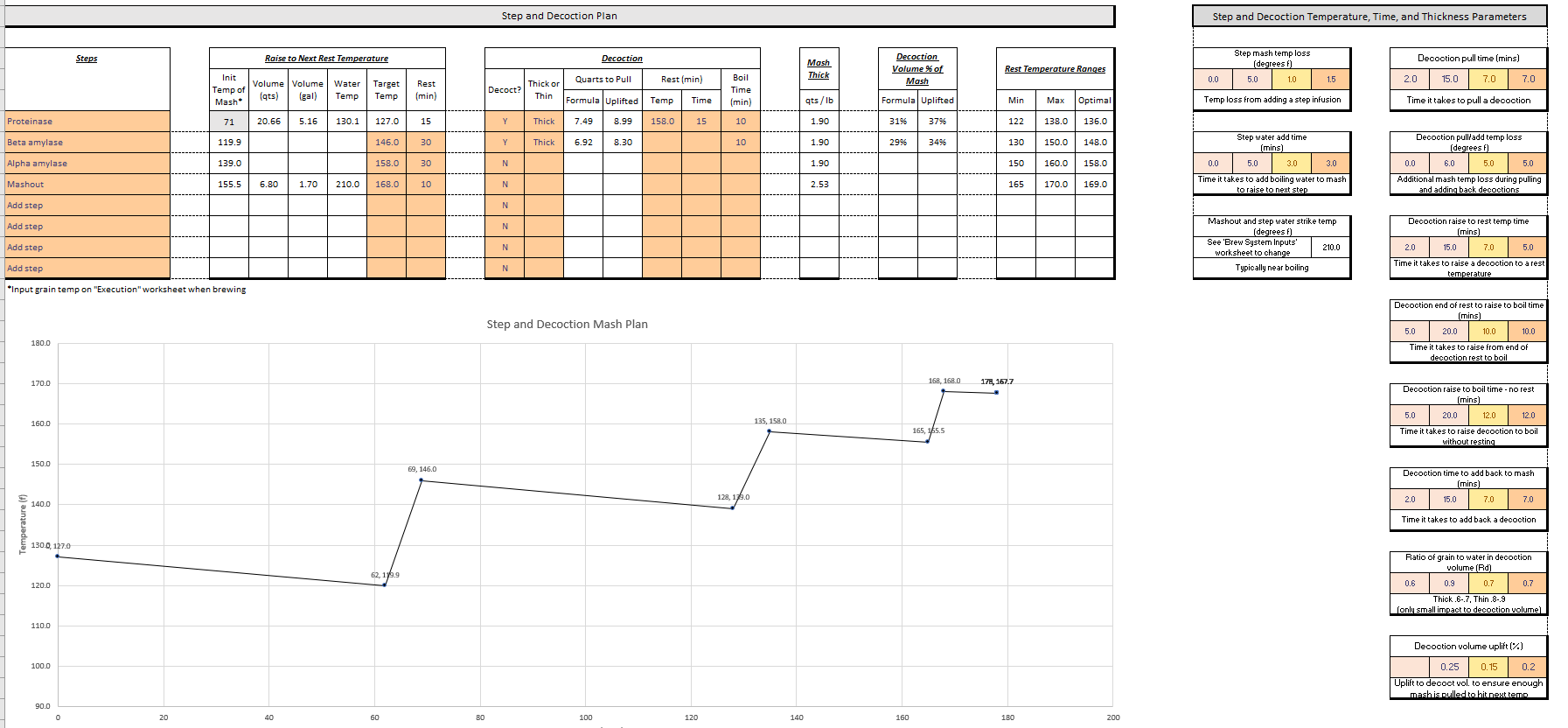

Let's get to the fun stuff, I mashed in with 5 gallons of water to raise temp to 100 degrees then pulled what I thought was a tick decoction of approximately 2/3 of the mash, which was almost 4 gallons. Raised the decoction to 159 then rested for 20 minutes, then raised it to a boil for 10 minutes, and added it back to the main mash. This is where things got wonky. The main mash was supposed to settle back at 149, but mine clocked in at 168! Fortunately, I had some cold water on hand just in case this happened, so I added about half a gallon of cold water to bring the temp down to 150, where it rested for 10 minutes. I then pulled a thin decoction of 2.5 gallons and boiled it for 10 minutes and added it back to the main mash to raise temp to 167, and rested for 10 more minutes. Refractometer reading showed a pre boil OG of 1.046, instead of 1.036 as predicted, then proceeded with the boil and added 3/4 gallon cold water at end of the boil to bring OG down to 1.049.

A couple of observations

My efficiency was way higher than usual, I typically get around 75%, but this mash resulted in 92% efficiency.

I added about an hour and a half to my usual brew day. My typical set up is no sparge BIAB, so my brew day is usually around 4 hours.

It's still in the fermentor, so I don't have a OG yet, but I'm betting that I had a pretty highly fermentable wort, so I hope it doesn't finish too dry. I routinely get at least 80% attenuation with 34/70.

I think I over shot my initial temp after adding back my first decoction because my decoction was too big, or I pulled too much water with it and it wasn't thick enough, or a bit of both. I'd love some feedback if anyone has an answer for this.

Has anyone else that's done a decoction had similar results? Not sure if I'll attempt another one, we'll see how the beer turns out first but I'm glad I tried it, a good learning experience at the least.

I kept the grain bill simple with 9 pounds of Mecca Grade Vanora and 2 ounces of midnight wheat for a little color. Amber balanced water profile per Bru'n Water so I had to add 2 grams gypsum and 1.5 grams CaCl and some Campden to take out the chlorine, resulting in a mash pH of 5.41 15 grams of Perle first wort hop for a 70 minute boil and 21 grams in the whirlpool for 10 minutes at roughly 180 degrees. Fermented with 34/70 at 60 degrees.

Let's get to the fun stuff, I mashed in with 5 gallons of water to raise temp to 100 degrees then pulled what I thought was a tick decoction of approximately 2/3 of the mash, which was almost 4 gallons. Raised the decoction to 159 then rested for 20 minutes, then raised it to a boil for 10 minutes, and added it back to the main mash. This is where things got wonky. The main mash was supposed to settle back at 149, but mine clocked in at 168! Fortunately, I had some cold water on hand just in case this happened, so I added about half a gallon of cold water to bring the temp down to 150, where it rested for 10 minutes. I then pulled a thin decoction of 2.5 gallons and boiled it for 10 minutes and added it back to the main mash to raise temp to 167, and rested for 10 more minutes. Refractometer reading showed a pre boil OG of 1.046, instead of 1.036 as predicted, then proceeded with the boil and added 3/4 gallon cold water at end of the boil to bring OG down to 1.049.

A couple of observations

My efficiency was way higher than usual, I typically get around 75%, but this mash resulted in 92% efficiency.

I added about an hour and a half to my usual brew day. My typical set up is no sparge BIAB, so my brew day is usually around 4 hours.

It's still in the fermentor, so I don't have a OG yet, but I'm betting that I had a pretty highly fermentable wort, so I hope it doesn't finish too dry. I routinely get at least 80% attenuation with 34/70.

I think I over shot my initial temp after adding back my first decoction because my decoction was too big, or I pulled too much water with it and it wasn't thick enough, or a bit of both. I'd love some feedback if anyone has an answer for this.

Has anyone else that's done a decoction had similar results? Not sure if I'll attempt another one, we'll see how the beer turns out first but I'm glad I tried it, a good learning experience at the least.

Last edited:

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)