I have been brewing about 20 or 25 years and have always dreamed of building a brew stand/system. Well I'm not getting any younger and I'm tired of horsing kegs full of hot liquids around to try to do an occasional all grain. I figured I'd share pictures and ideas as this project goes along and tap into the experience and expertise available in this forum.

So here goes:

I've settled on a single tier HERMS system. I'm hoping to start simple with manual heat control, hoses and a single pump and add to it as time and finances allow. This way I hope I can start brewing some all grain batches on it pretty quickly.

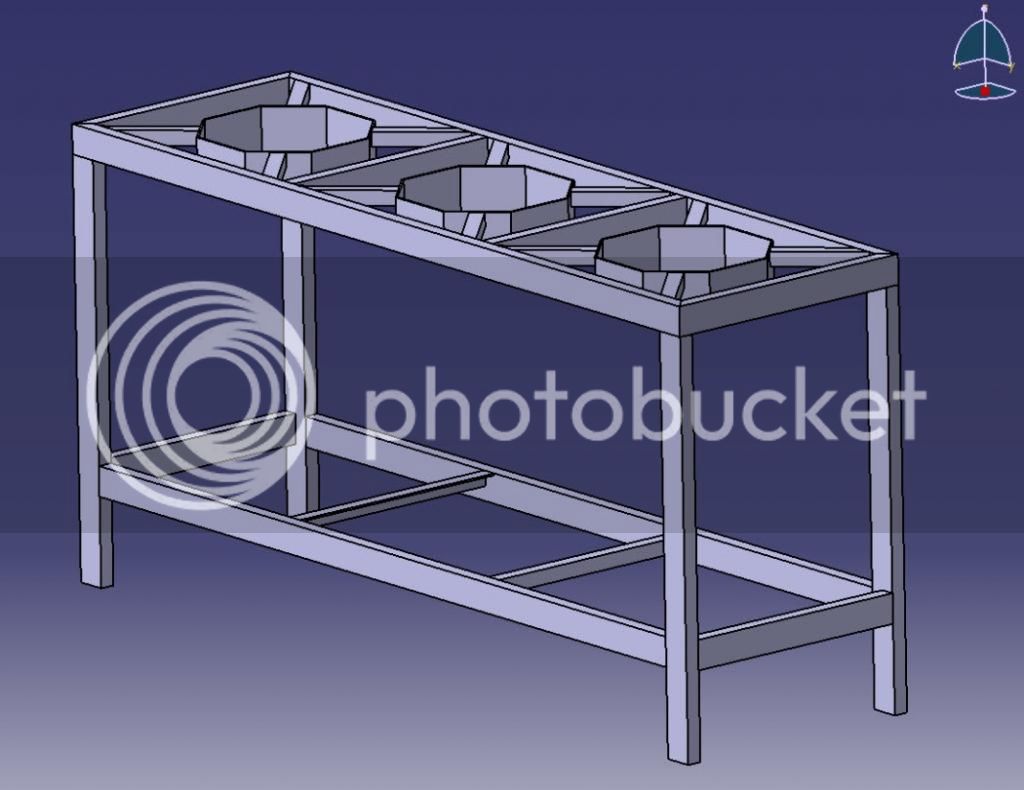

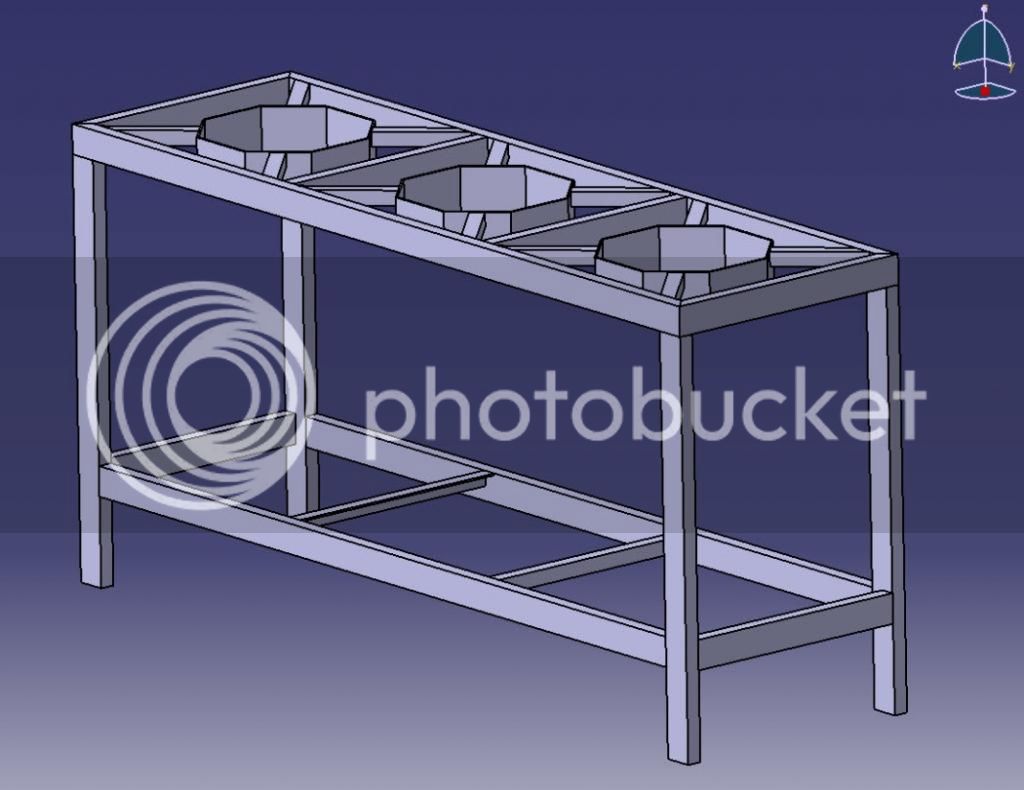

First thing of course is a bench

which a good friend who I introduced to home brewing is helping me

That's kinda where I'm at. A lot of thinking and a little doing. So let the flow of thoughts and ideas begin.

Happy Brewing

So here goes:

I've settled on a single tier HERMS system. I'm hoping to start simple with manual heat control, hoses and a single pump and add to it as time and finances allow. This way I hope I can start brewing some all grain batches on it pretty quickly.

First thing of course is a bench

which a good friend who I introduced to home brewing is helping me

That's kinda where I'm at. A lot of thinking and a little doing. So let the flow of thoughts and ideas begin.

Happy Brewing

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)