chiefairwrench

Junior Member

Well you just made my day thanks for sharing your pics and thoughts.

Looks good when are you building the lift?

That is awesome great job

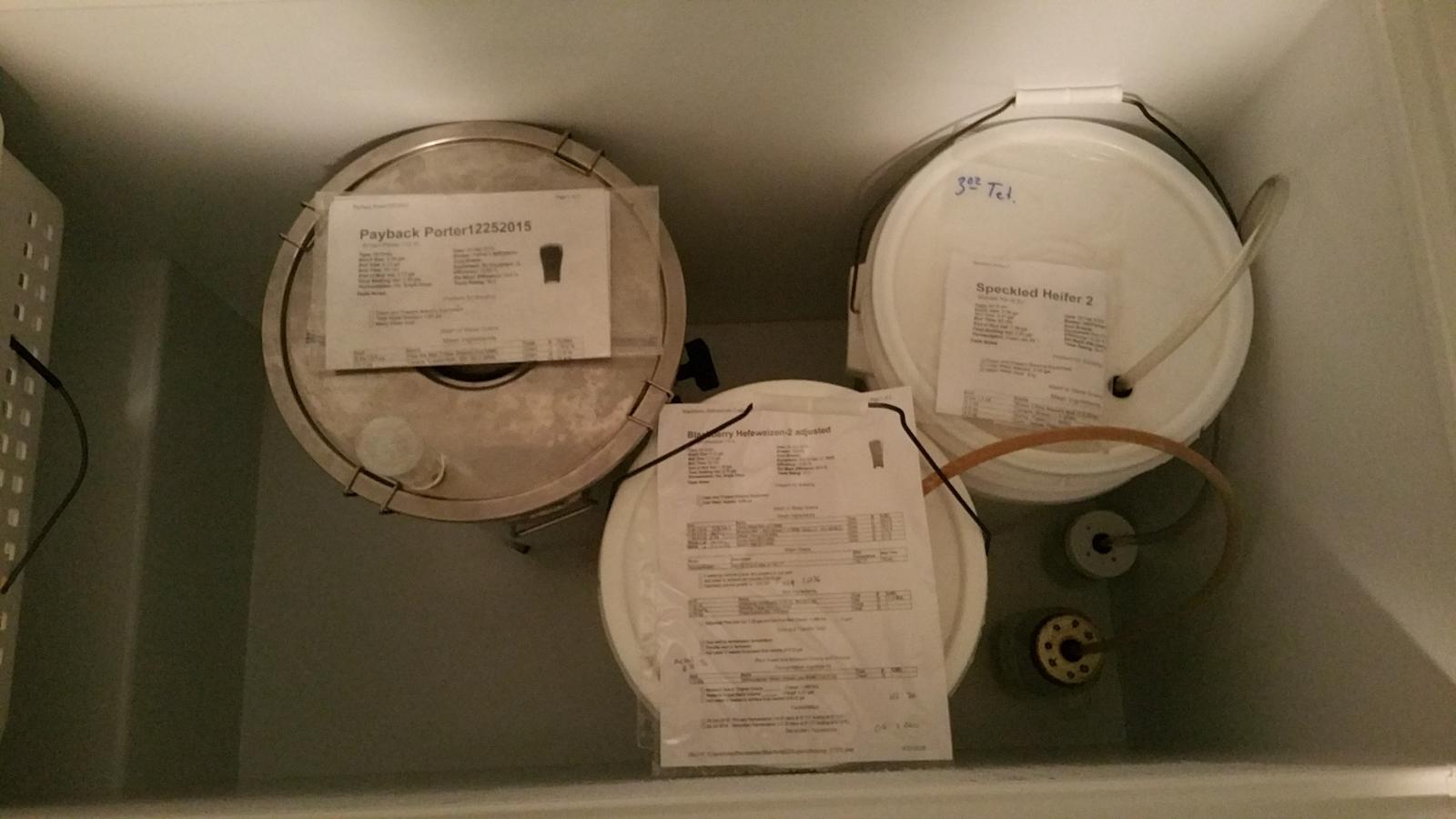

The stands were bolted together due to several people do not weld or does not have the money to get them welded. Mine is welded and bolted the yellow stand is way for every one with simple tools to make a great single pot vessel stand that takes up very small room. To wrap diamond plate take a little practice and skill. You have to use a soft rubber hammer like in video 1 cut L at each corner with the board in place tap from the middle going left hand and right hand ALWAYS starting from the middle do not get in a hurry you want to bend the metal together(same angle at a time). As far as height great glad you are designing a stand that fits you I would differently do the same thing. I have made custom stand with this design it very simple a few leg adjustments is all I have to do it is very simple. Also there 3 models each was design for different storage room and preference do you have the plans? Model two four leg change would change the height of the table and make it more enjoyable for you to use.Good luck I really like to see your stand when your done I am sure you will have a lot of fun with your project. If you like since we talked on facebook I could show you how I did it and you can see mine stand we use them for training introducing people how to BIAB all grain if that would help ya.

Great ideas are you going to use steel and aluminum to keep the weight down? My larger stand can be heavy when taking it to other sites I normally take the yellow stand and purple stand burners add a good amount of weight