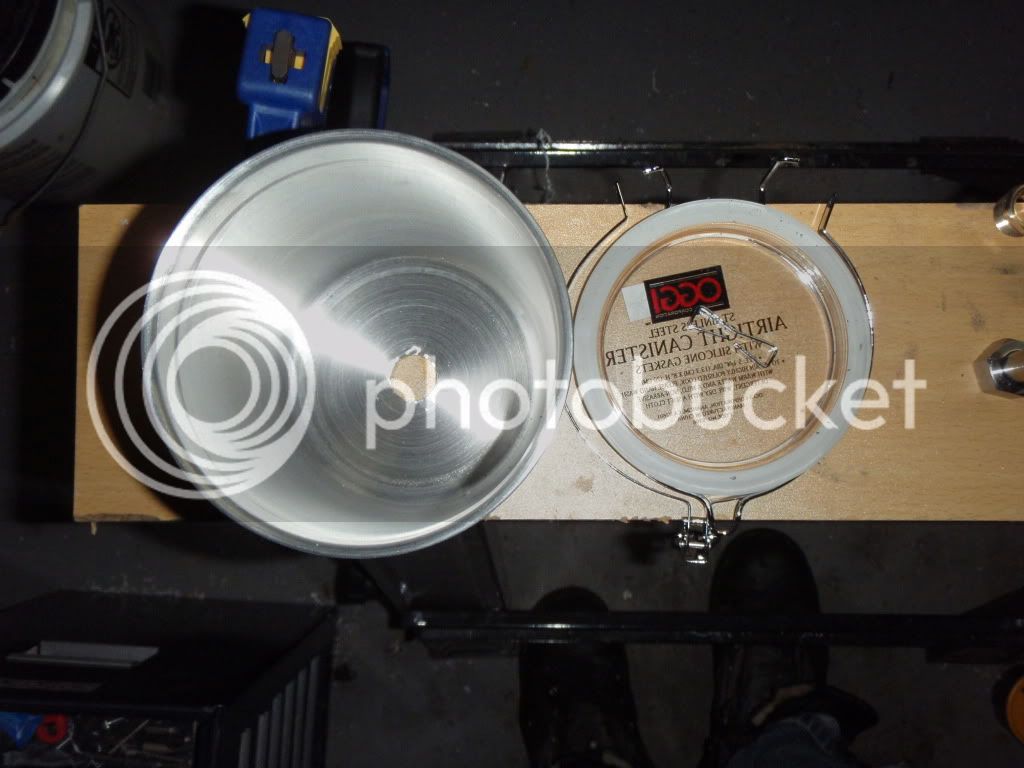

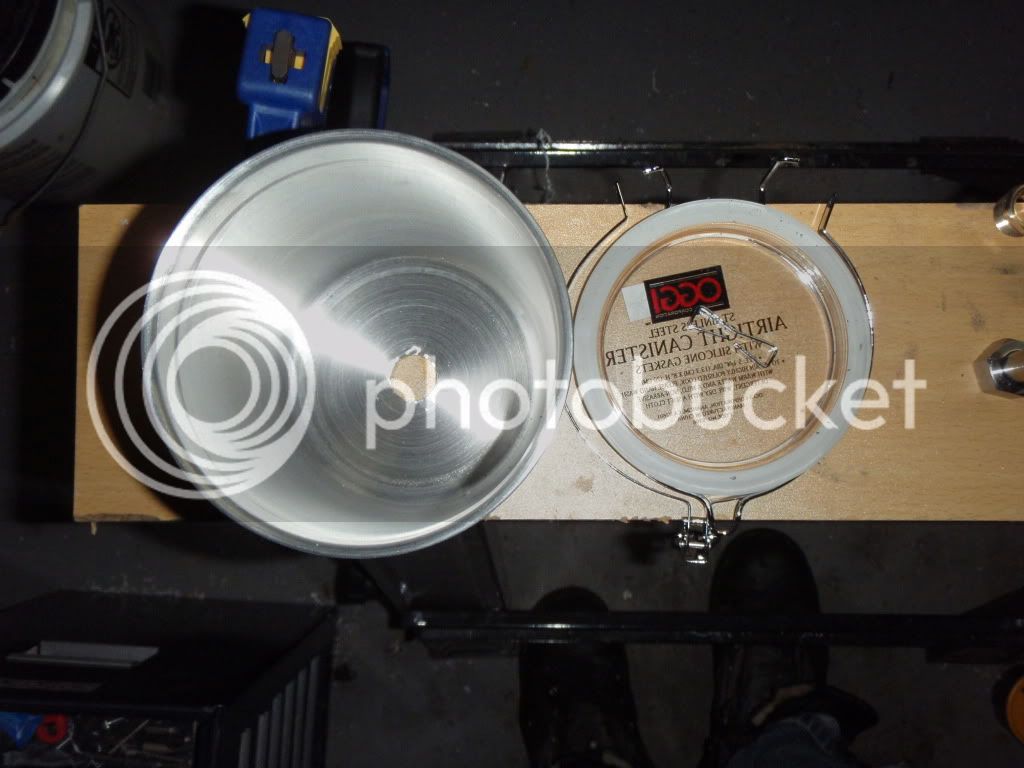

Today I was at Bed Bath and Beyond looking for sheets, which I didn't get. What I did get was this:

I know that there are several threads on hopbacks, but I didn't see a blow by blow how to, so here's how I did it. I won't include in and out fittings, since those will be dictated by your particular system. Also, I have not actually put this to use yet, but I will tomorrow at Big Brew, and will report back with the results.

Shopping list:

60 oz stainless canister - bedbathandbeyond - $13

Stainless sink strainer - bedbathandbeyond - $3 (I couldn't find this on the website, but it was in the store)

2 ea 1/2" x 3/8" npt bushing - homedepot - $5

1/2" fpt x 1/2" fpt coupler - homedepot - $5

Silver solder and flux (already had these)

First up was to disassemble the canister by pinching the wire that wraps around the lid, followed by removing the bowtie shaped clamp that holds the band in place, and finally removing the band with latch. Set these aside.

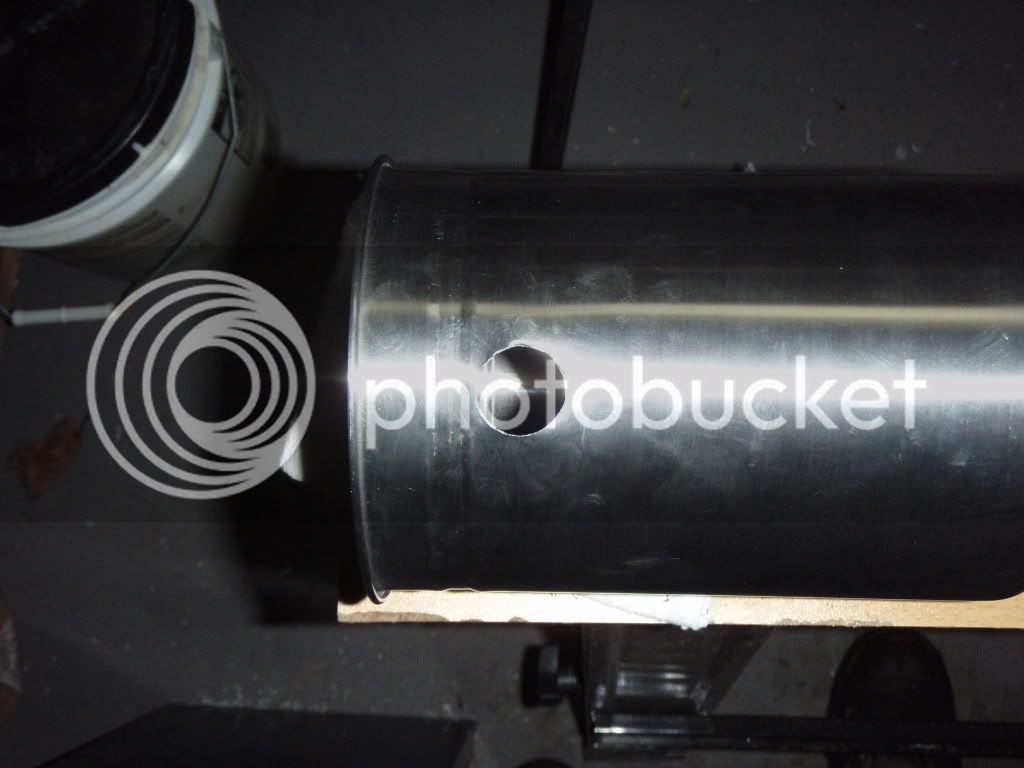

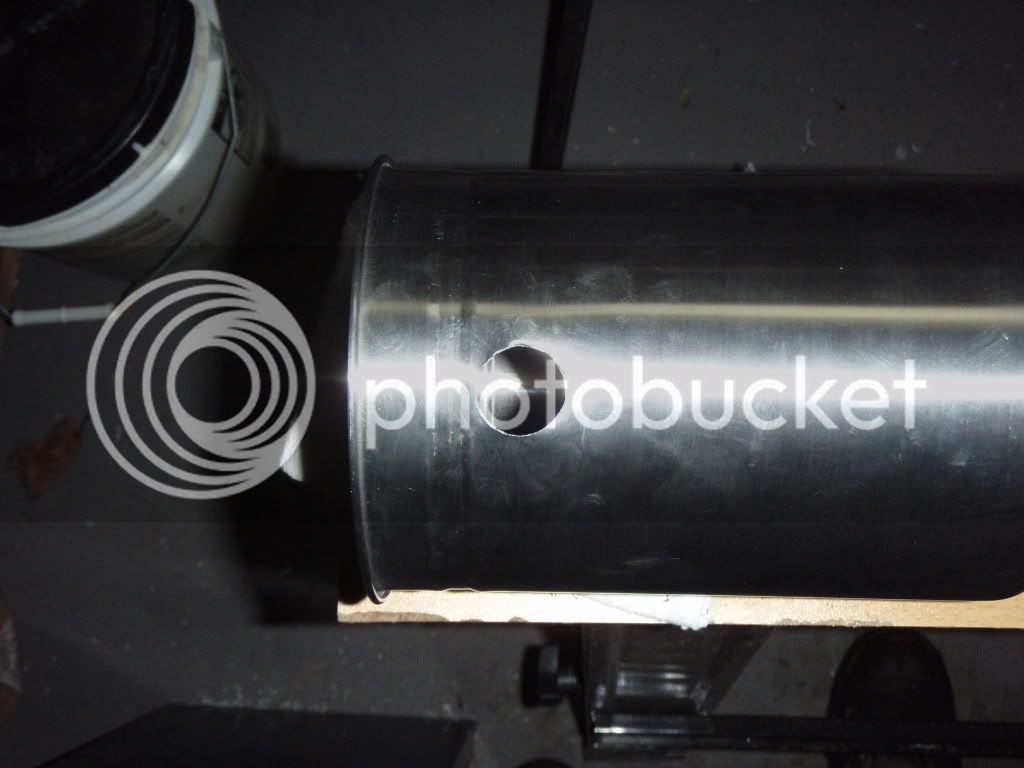

Next, mark the location for the in and out fittings. The in should go as close to the recess that the band sits in as possible without the fitting contacting the recess. The out will be centered in the bottom. Once these are marked hit them with a center punch carefully. The canister is made of very thin material, so not a lot of force is needed here. Once you have these marked drill them out to 13/16". For this I used a 1/8" drill, followed by a 3/8", followed by a step bit. You have to be very careful drilling these holes, as the thin material of the canister is easily mangled. I suggest using very light pressure and very slow drill speed. The goal in this step is to make a clean hole without mangling the material, so take you time. This is what you want when finished.

After you have two clean hole drilled clean them up with a rattail file followed by some 60 grit sandpaper.

I know that there are several threads on hopbacks, but I didn't see a blow by blow how to, so here's how I did it. I won't include in and out fittings, since those will be dictated by your particular system. Also, I have not actually put this to use yet, but I will tomorrow at Big Brew, and will report back with the results.

Shopping list:

60 oz stainless canister - bedbathandbeyond - $13

Stainless sink strainer - bedbathandbeyond - $3 (I couldn't find this on the website, but it was in the store)

2 ea 1/2" x 3/8" npt bushing - homedepot - $5

1/2" fpt x 1/2" fpt coupler - homedepot - $5

Silver solder and flux (already had these)

First up was to disassemble the canister by pinching the wire that wraps around the lid, followed by removing the bowtie shaped clamp that holds the band in place, and finally removing the band with latch. Set these aside.

Next, mark the location for the in and out fittings. The in should go as close to the recess that the band sits in as possible without the fitting contacting the recess. The out will be centered in the bottom. Once these are marked hit them with a center punch carefully. The canister is made of very thin material, so not a lot of force is needed here. Once you have these marked drill them out to 13/16". For this I used a 1/8" drill, followed by a 3/8", followed by a step bit. You have to be very careful drilling these holes, as the thin material of the canister is easily mangled. I suggest using very light pressure and very slow drill speed. The goal in this step is to make a clean hole without mangling the material, so take you time. This is what you want when finished.

After you have two clean hole drilled clean them up with a rattail file followed by some 60 grit sandpaper.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)