Oldskewl

Well-Known Member

Looks like that link is dead.

Looks like that link is dead.

Looks like that link is dead.

1 hp motor?Monster Mill MM-2 Pro with heat treated rollers

Perfect-I'm going to try it.

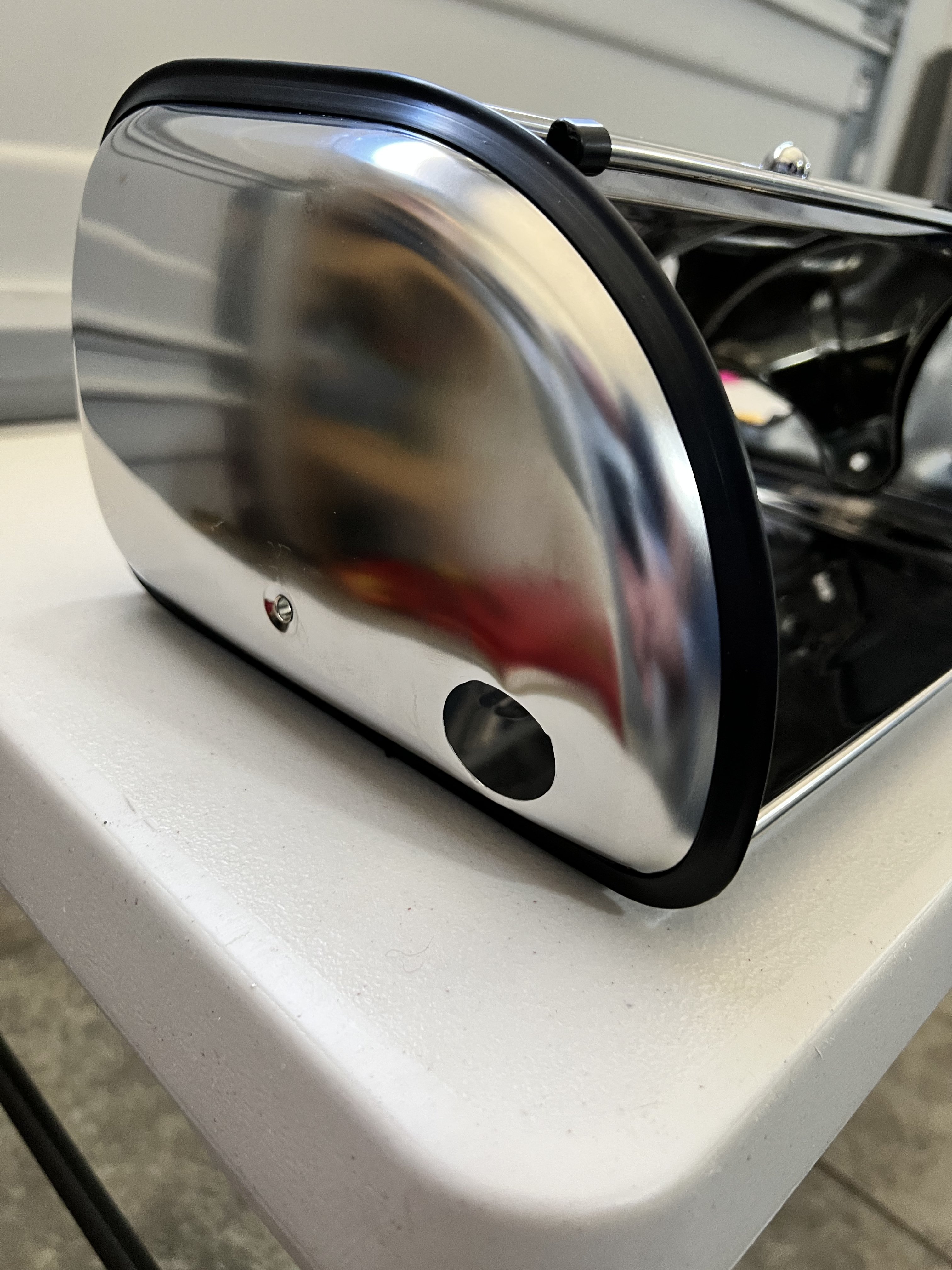

My grain mill setup sitting on a Craigslist buffet cart with room for my digital scale.

View attachment 359698

yes you could wire a drum switch to it to give it both forward and reverse.I tried reversing the supply wires to no avail, and asked williams support. Was told it cant be reversed, that it is hard wired for their mill. Perhaps it is the wires between the switch and the motor that need to be reversed?

At any rate, the bottom mount provided a more elegant solution so it was a good problem even if only due to my cluelessness.

Thanks much!Very neat and well contained, It's visually pleasing as well. Nice build.