raouliii

Well-Known Member

I bought two of everything for a grain mill project with my brew buddy. We decided that we really only needed one between us. I am selling the second set. This is a very heavy-duty, expensive, setup. However, it is almost bullet-proof, and will crush just about anything you throw into it. Most of the items were purchased via ebay as new or in lightly used condition at prices deeply discounted from retail pricing.

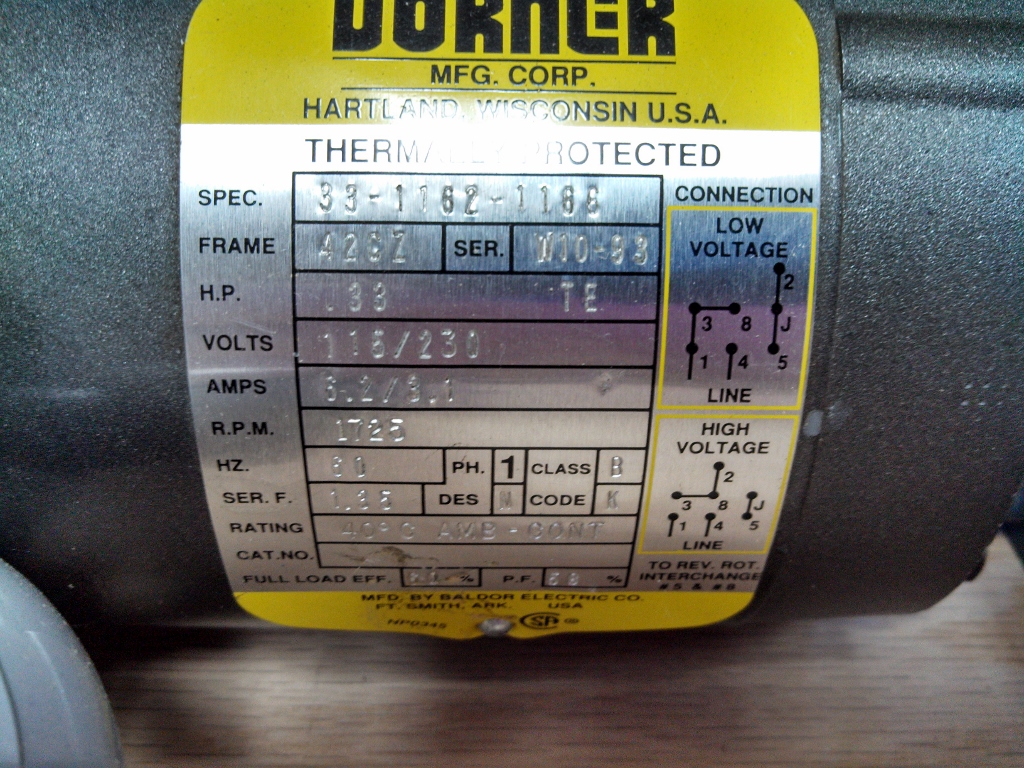

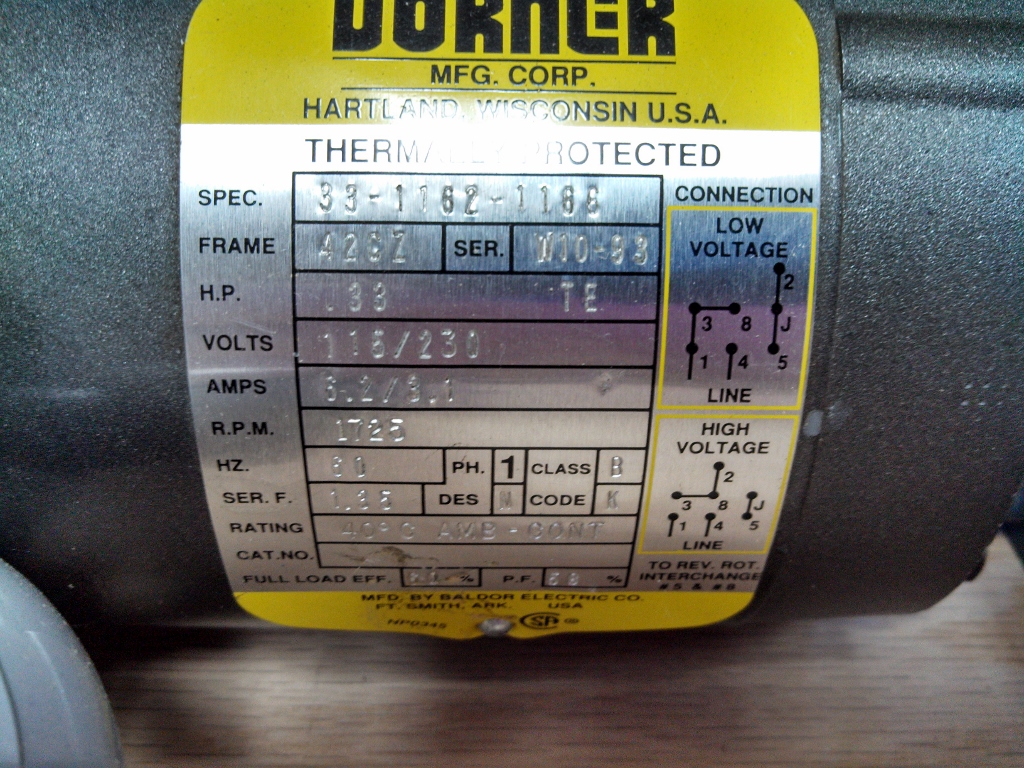

A 1/3hp 120/240vac, TEFC, Baldor motor, 42CZ frame, 1725rpm, wired for 120vac.

A 10:1 Boston Gear 90deg reducer, 1/2" output shaft.

Lovejoy 1/2" couplers and spider are included.

A custom mounting board.

The reducer outputs at 172.5rpm. The 42CZ frame size is smaller in diameter to the much more common 56 frame, which takes up less space on the board. Everything is wired up with a toggle switch for crushing or clearing jams. Mounted on oak plywood, 23-7/8"wide x 22"deep, with hole cut to match a Monster Mill, MM-2 bolt spacing of 2-7/8" x 6-5/8" with shim. The motor/reducer combination results in a 104 in-lb torque rating. This is mill ready. The plywood is unfinished on the edges but for an additional fee I can cut to a smaller dimension and or apply oak banding.

I've got $260 in the motor, $80 in the reducer, about $50 in the electrical and couplers. A number of hours were put into design and fabrication of the electrical, cutouts and mounting.

I am asking $400 plus shipping. The assembly weighs in at about 35lbs.

Another reminder, this assembly is designed and tested for a Monster Mill, MM-2 with 1/2" input shaft. A MM-2 with 3/8" input shaft would require an additional coupler purchase. A MM-3 has the same bolt spacing but additional shims for the reducer and motor would need to be fabricated to raise the motor/reducer to mate with the input shaft. MM2-2.0 and MM3-2.0 have different bolt spacings and would need a new board designed and built. The same would apply for any other mill. I would be able to provide these changes for an additional fee but could not guarantee a fit without having the mill shipped to me for fitting.

Please ask any questions you may have. I have tried to provide all the information I could think of but am sure I left something out.

The mill below is the one that I am KEEPING, but is a representation of the item for sale above with a mill and hopper attached. The item shown in operation below is not part of this sale.

A 1/3hp 120/240vac, TEFC, Baldor motor, 42CZ frame, 1725rpm, wired for 120vac.

A 10:1 Boston Gear 90deg reducer, 1/2" output shaft.

Lovejoy 1/2" couplers and spider are included.

A custom mounting board.

The reducer outputs at 172.5rpm. The 42CZ frame size is smaller in diameter to the much more common 56 frame, which takes up less space on the board. Everything is wired up with a toggle switch for crushing or clearing jams. Mounted on oak plywood, 23-7/8"wide x 22"deep, with hole cut to match a Monster Mill, MM-2 bolt spacing of 2-7/8" x 6-5/8" with shim. The motor/reducer combination results in a 104 in-lb torque rating. This is mill ready. The plywood is unfinished on the edges but for an additional fee I can cut to a smaller dimension and or apply oak banding.

I've got $260 in the motor, $80 in the reducer, about $50 in the electrical and couplers. A number of hours were put into design and fabrication of the electrical, cutouts and mounting.

I am asking $400 plus shipping. The assembly weighs in at about 35lbs.

Another reminder, this assembly is designed and tested for a Monster Mill, MM-2 with 1/2" input shaft. A MM-2 with 3/8" input shaft would require an additional coupler purchase. A MM-3 has the same bolt spacing but additional shims for the reducer and motor would need to be fabricated to raise the motor/reducer to mate with the input shaft. MM2-2.0 and MM3-2.0 have different bolt spacings and would need a new board designed and built. The same would apply for any other mill. I would be able to provide these changes for an additional fee but could not guarantee a fit without having the mill shipped to me for fitting.

Please ask any questions you may have. I have tried to provide all the information I could think of but am sure I left something out.

The mill below is the one that I am KEEPING, but is a representation of the item for sale above with a mill and hopper attached. The item shown in operation below is not part of this sale.

Last edited by a moderator:

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)