ihavenonickname

Well-Known Member

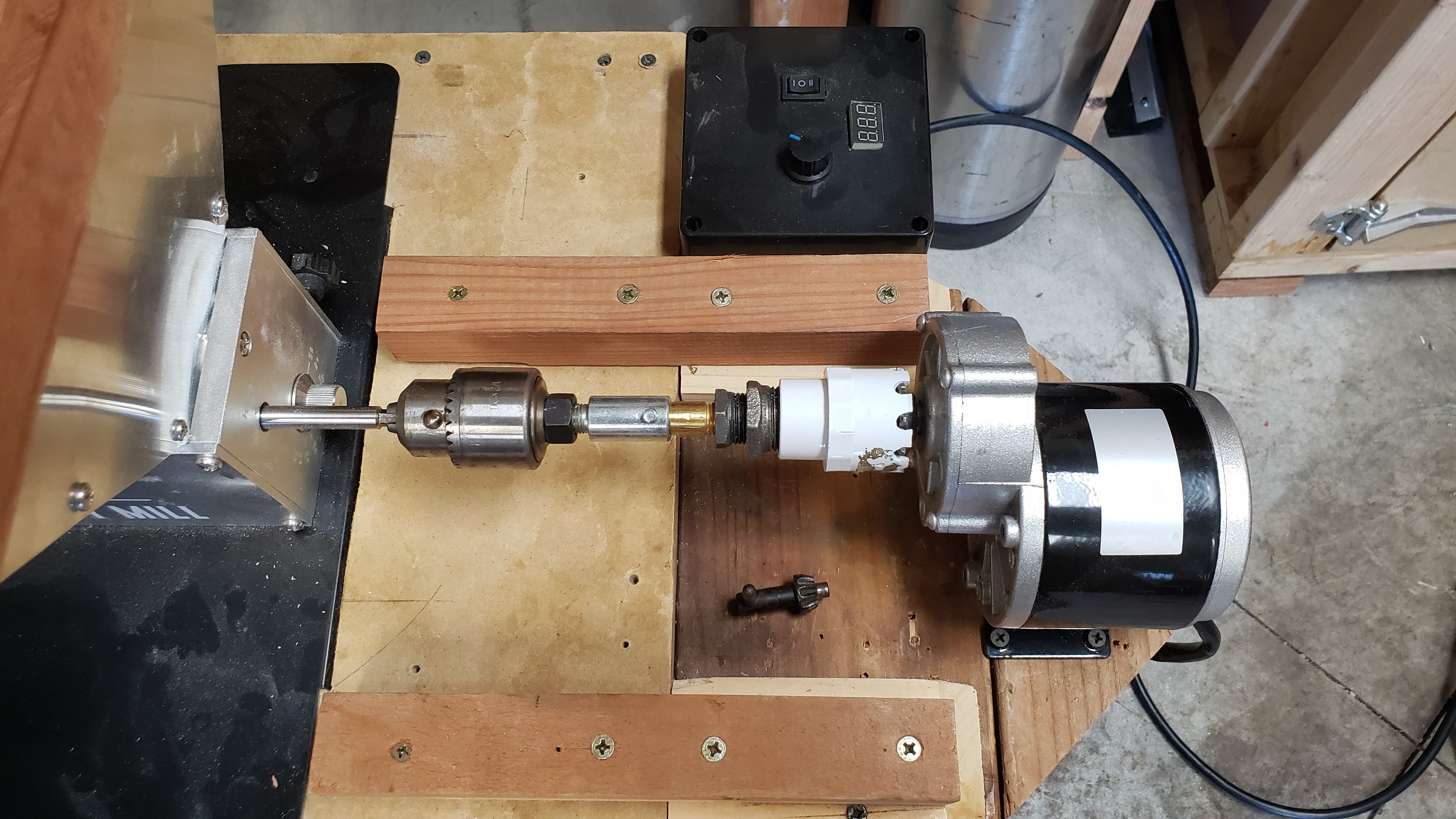

I’ve looked around at some options for motorizing my mill, lots of expensive options out there. But one build seemed to be totally happy with a very easy to use cheap small motor from China. It’s only 30 bucks and available from Amazon. Already geared to run 160rpm and capable of a good amount of torque, apparently - 10 kg.cm

see any big problems with this am I missing something? It’s so much cheaper than the 200 dolllar options, and easier than figuring out gears and pullys with a refurbed motor.

BRINGSMART 12V 160rpm DC Worm Gear Motor 10kg.cm Self-locking Engine Reversed Mini Turbine Geared Motor for DIY Robot Rotating Table Door Lock Curtain Machine (12V 160rpm) Amazon.com: BRINGSMART 12V 160rpm DC Worm Gear Motor 10kg.cm Self-locking Engine Reversed Mini Turbine Geared Motor for DIY Robot Rotating Table Door Lock Curtain Machine (12V 160rpm) : Electronics

edit: follow up to the idea above - I got a response from a poster who got this little motor working great at first. He said after 5 brews the motors burnt out and he replaced it.

it seems the better (and still cheap) solution is to get a corded drill with a speed dial and lock, see my post on next page)

see any big problems with this am I missing something? It’s so much cheaper than the 200 dolllar options, and easier than figuring out gears and pullys with a refurbed motor.

BRINGSMART 12V 160rpm DC Worm Gear Motor 10kg.cm Self-locking Engine Reversed Mini Turbine Geared Motor for DIY Robot Rotating Table Door Lock Curtain Machine (12V 160rpm) Amazon.com: BRINGSMART 12V 160rpm DC Worm Gear Motor 10kg.cm Self-locking Engine Reversed Mini Turbine Geared Motor for DIY Robot Rotating Table Door Lock Curtain Machine (12V 160rpm) : Electronics

edit: follow up to the idea above - I got a response from a poster who got this little motor working great at first. He said after 5 brews the motors burnt out and he replaced it.

it seems the better (and still cheap) solution is to get a corded drill with a speed dial and lock, see my post on next page)

Last edited:

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)