I went to the habitat store looking for bigger motor and they had several 1/6 - 3/4 HP motors, machine shop style for cheap. This would look really cool but I would have to find a couple of pulleys to drop the speed down 1:10, pulleys seem kind of expensive.

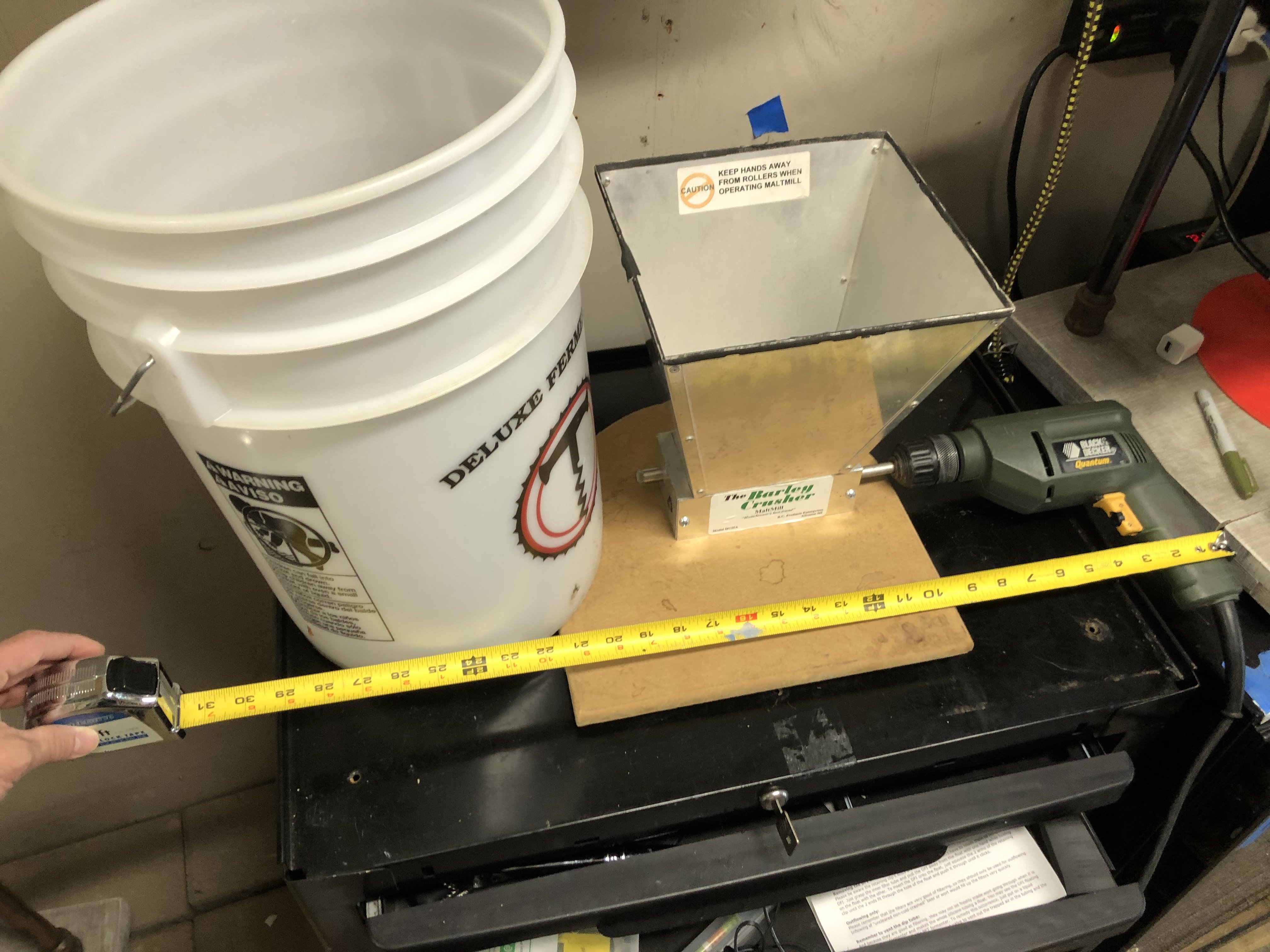

But I also found a rad little hand drill with a speed control dial and trigger lock. I’ll be able to set the speed nice and low, flip it on and let it do the work hand free. I just need a few straps and lock it down to the base.

So just as suggested by

@bracconiere above this is a great cheap solution for a dedicated, hand free mill cabinet.

thanks for everyone’s help.

View attachment 749490

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)