Hello!

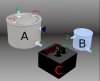

So, I have drafted up a concept of what I am planning.

As you can see, it is a large stock pot that has had a thermometer, cooling coil and siphon tube modified onto it.

I bought four glass carboys, but then found out later that they were not capable of being heated to the temperatures found after mashing. Basically, if I dump my hot mash into these carboys they will shatter.

The solution it seems is to create a way to cool the mash before putting it into the carboys. The problem then becomes how to avoid contamination.

My idea is to put a glass siphoning tube into my mashing pot. The mash will be brought to a full boil. Then, I will use the cooling coil to bring it down to a reasonable temperature. After that, I will use the siphon to draw it into the carboy(s) without exposing it to contamination.

The carboys have rubber stops for lids. I plan to put a glass siphoning tube into them just like the mash pot.

The first step will be to put four holes into the stock pot:

There are three at the top. Two are for the cooling coil and the other is for the siphoning tube. The one on the side is for the thermometer.

Next, I will put rubber stops into the holes to seal them off:

This should form a pretty decent seal.

Finally, I will put small holes into the rubber stops and force my instruments through them:

It should all be pretty secure at that point. I figure if I draw a siphon and quickly pop the siphoning line onto the glass tube from the carboy, I should be able to avoid much contamination.

Does anyone have any ideas or suggestions? I want to add some kind of filter at the bottom to collect the grain and such but haven't worked that out yet.

So, I have drafted up a concept of what I am planning.

As you can see, it is a large stock pot that has had a thermometer, cooling coil and siphon tube modified onto it.

I bought four glass carboys, but then found out later that they were not capable of being heated to the temperatures found after mashing. Basically, if I dump my hot mash into these carboys they will shatter.

The solution it seems is to create a way to cool the mash before putting it into the carboys. The problem then becomes how to avoid contamination.

My idea is to put a glass siphoning tube into my mashing pot. The mash will be brought to a full boil. Then, I will use the cooling coil to bring it down to a reasonable temperature. After that, I will use the siphon to draw it into the carboy(s) without exposing it to contamination.

The carboys have rubber stops for lids. I plan to put a glass siphoning tube into them just like the mash pot.

The first step will be to put four holes into the stock pot:

There are three at the top. Two are for the cooling coil and the other is for the siphoning tube. The one on the side is for the thermometer.

Next, I will put rubber stops into the holes to seal them off:

This should form a pretty decent seal.

Finally, I will put small holes into the rubber stops and force my instruments through them:

It should all be pretty secure at that point. I figure if I draw a siphon and quickly pop the siphoning line onto the glass tube from the carboy, I should be able to avoid much contamination.

Does anyone have any ideas or suggestions? I want to add some kind of filter at the bottom to collect the grain and such but haven't worked that out yet.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

Till next time

Till next time