Beer Snob

Well-Known Member

It has begun. Early... this way I stay saine.

The method I am using can be found here at Socks Monkeys and Beer.

http://www3.telus.net/sockmonkeysandbeer/beer/HowIBrew/howIbrew.html

Here it is at the start...

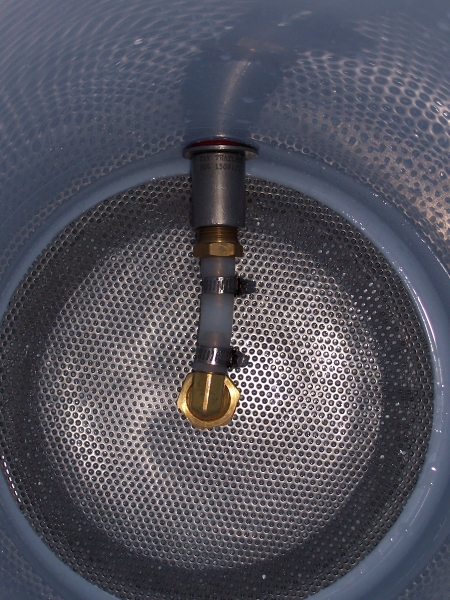

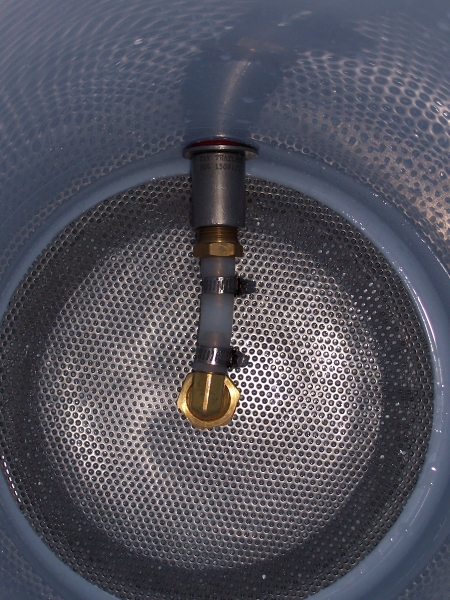

This time I am hoping that this connection will hold... high temp tubbing and 2 stainless steel clamps.

1 gal in.... you think the paddle will stap this time... damm... did not get a second one.....

2 gals in.... paddle still in one piece!

At 3 gal I started the timer and hit 157 degrees! (ProMash RULES!)

The method I am using can be found here at Socks Monkeys and Beer.

http://www3.telus.net/sockmonkeysandbeer/beer/HowIBrew/howIbrew.html

Here it is at the start...

This time I am hoping that this connection will hold... high temp tubbing and 2 stainless steel clamps.

1 gal in.... you think the paddle will stap this time... damm... did not get a second one.....

2 gals in.... paddle still in one piece!

At 3 gal I started the timer and hit 157 degrees! (ProMash RULES!)

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)