I'm adding a sight glass to Thing1, because:

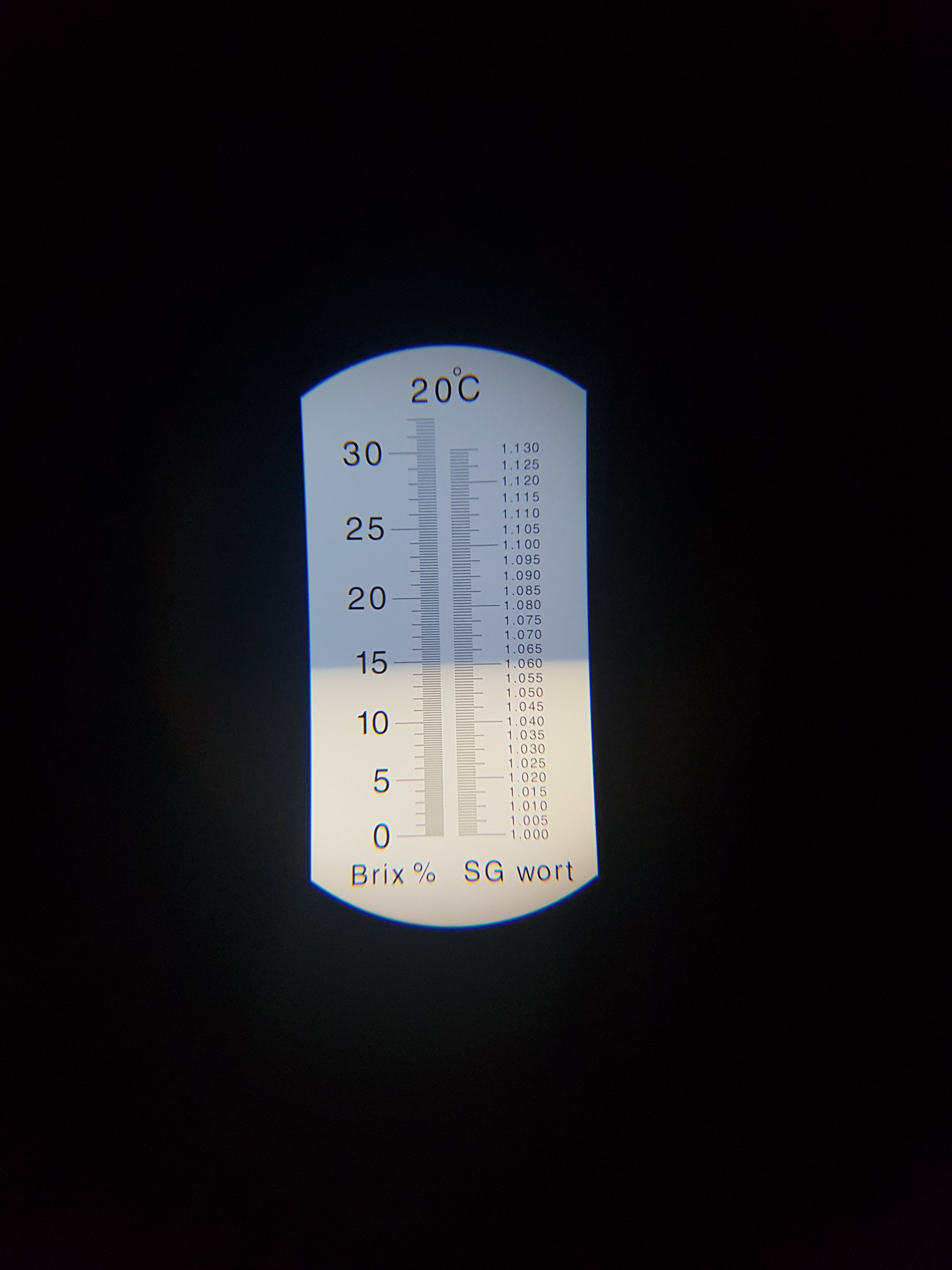

1) I'm going to be changing up my batch sizes because of some work I've been doing on fermentors or rather kegmentors - using kegs as pressurized fermentation, settling and possibly serving vessels, AKA unitanks. Because I won't be brewing the same batch size over and over, I need to get my volumes right when brewing oddball batch sizes. Thus I need a sight glass.

Aside. I've got the ingredients for 2 batches sitting in my basement. I really wanted to brew 2 or 3 batches this weekend, but I was working on fermentors for the batches to go into. Hopefully I brew a couple evenings this week.

2) I can't see into the kettle during the sparge, so I never know how much is actually in the kettle. I've been dipping a SS rod into the kettle during the sparge and calculating the volume based on that, but that is a pain.

3) I want to see how much suction is on the grain bed during recirculation. You can get this by comparing the hydraulic head at the bottom of the kettle (shown by the sight glass) with the liquid level on top of the bed. The difference between the two is the suction on the bed.

Said suction exists even with the standpipe. If there was no suction on the bed, the standpipe would be full to the top of the bed. This happens if you turn the pump off. But when you run the pump, the standpipe level drops because of the suction on the bed.

Now I can throttle the pump so I have a fixed amount of suction on the grain bed. I can also easily measure the recirc flow and calculate a flow parameter for the grain bed and start making educated decisions about mash step times, when to add hulls to improve bed flow, etc.

I've put this off for a while because I didn't want to void the warranty on Thing1. Oh... wait... LOL.

Drill the pilot hole. I put an old furniture moving blanket on my work bench when I work on shiny kettles so I don't scratch them. Plus they don't roll around as much.

Enlarge it with a step bit. Clean it up a bit.

Clean everything up with sandpaper and acetone and bolt it down so it doesn't move while soldering. Apply flux.

I solder stuff that isn't too big, isn't heated by a flame and isn't under pressure. FYI, this is a 1/2" NPT coupler that I cut in half. I don't want anything protruding into my kettle, so it goes on the outside.

Soldered piece, with a compression elbow added.

The solder job isn't artistic, but it works. It looks better than a TIG job where the metal got cooked. It is hard to control where the solder goes. This joint was strong enough that I tightened the pipe thread with a Crescent wrench without holding the coupler with a wrench.

I used 95/5 solder, Stay Brite flux and a simple propane torch. It took 5 minutes to solder this. This is pretty much as soldered with no cleanup. I wiped it with a rag because the flux is nasty.

One of the nice things about soldering a fitting is that it can be easily removed and cleaned up with some heat and a stainless steel wire brush if you change your mind.

Here is how the tube seals in the fitting. You can't use a ferrule because the plastic tube will crack before you get enough force on the ferrule to compress it.

The tube is a 1/2" plastic racking tube. I'm using it because it is cheap, kinda shatter proof, safe it if does "shatter" and my LHBS carries them if I break one. I use 1/2" racking tubes as blow offs on my fermentors, so I have a few around anyway.

I could replace it with a glass tube, but I'd probably have to put a guard on it. With plastic I can pull it off and throw it in the sink to wash with everything else and not have to worry about breaking it. I could also just replace it.

This tube would probably get soft if it was sitting in boiling water. I've mounted it away from the kettle so that it stays cooler. I ran a similar tube as a sight glass on the kettles on my old propane rig. The tubes worked well even though they were also exposed to the burner heat coming up the side of the kettles.

Look, Ma - no leaks !

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)